Diamond cutting tools are not small devices used to give precious stones the proverbial "finishing touch". Rather, the diamonds themselves become part of the tool and do a convincing job. In this article, we reveal where and why diamond grinding tools are used and what benefits you might also be able to derive from them.

What are diamond grinding tools?

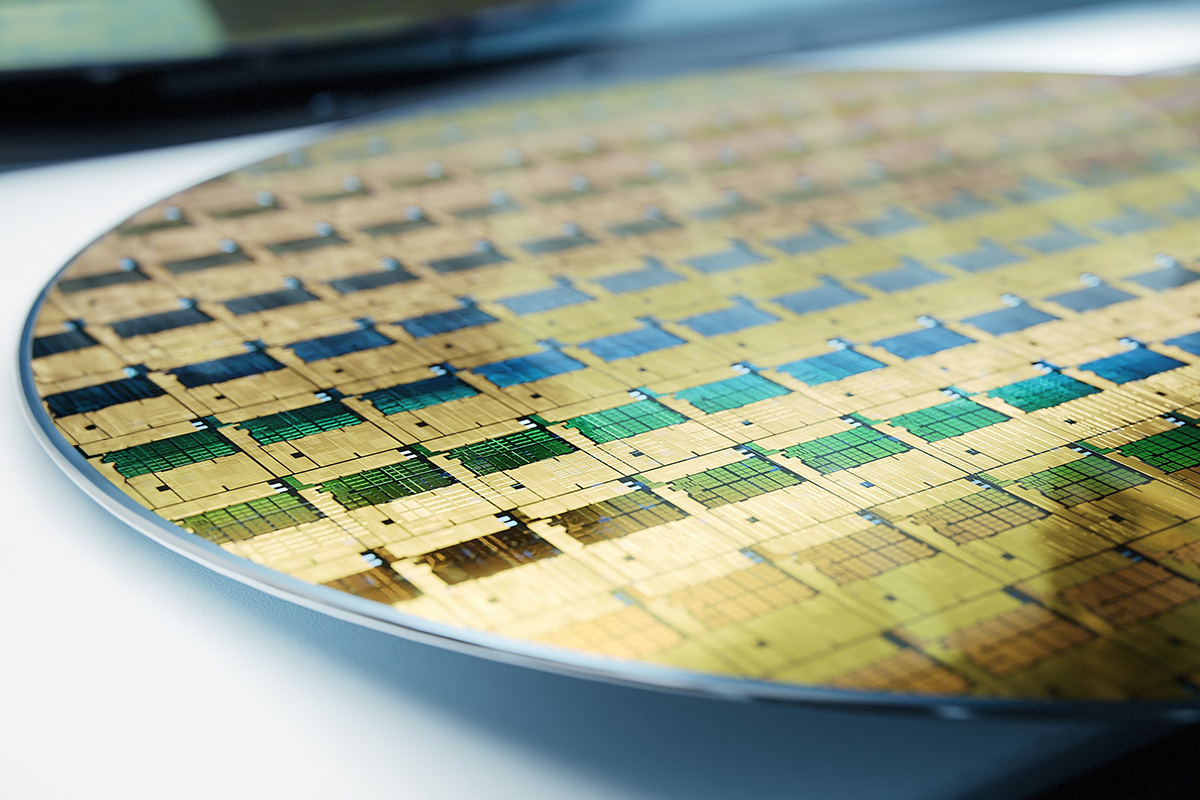

When people think of diamonds, their first association is often with high-quality jewellery. However, fine diamond dust or industrial diamonds (also known as Bort) are not used as decorative and prestigious objects. Due to their special properties, they are primarily used in the production of tools. In addition to the use of diamonds as a cutting material for tools such as drills or milling cutters, diamond grinding tools are also in high demand.

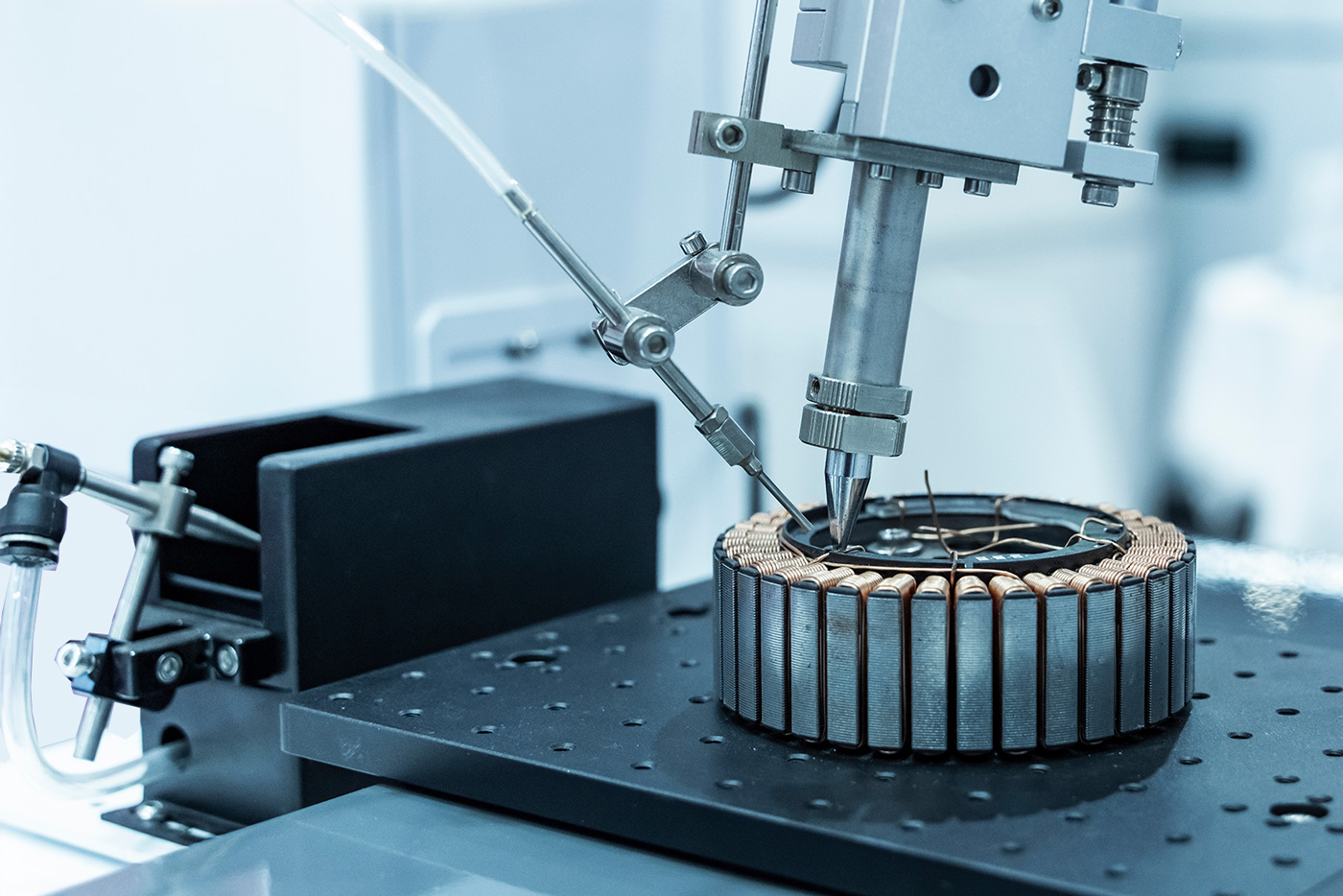

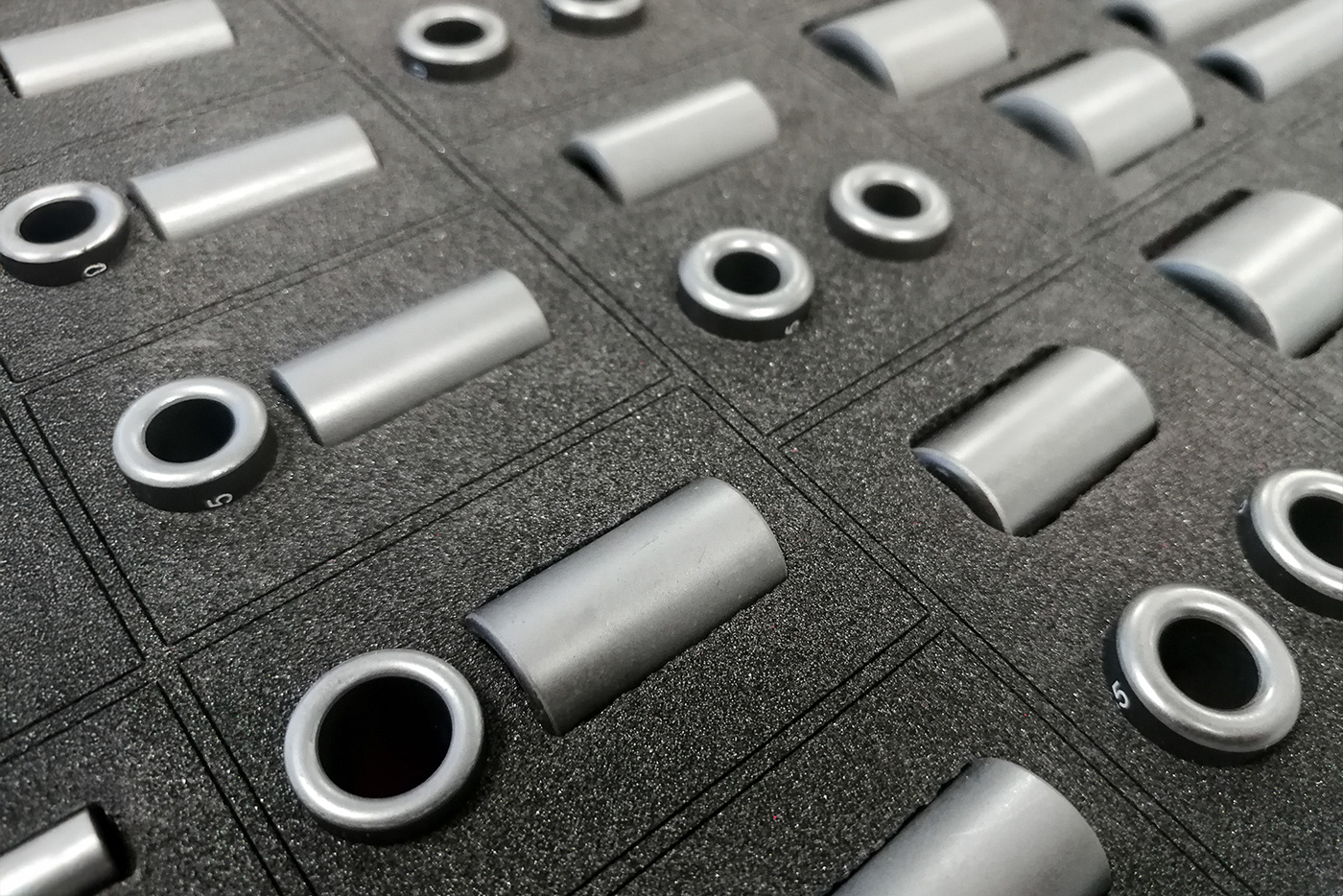

Here, the fine diamond dust is applied to grinding discs as an abrasive. This means that the entire grinding disc is not made of diamond. This production method would be too cost-intensive and time-consuming. Instead, the base body consists of a carrier material to which the diamond powder is bonded. Depending on the requirements and area of application, metals such as steel, synthetic resin mixtures or lightweight materials can be used as materials for the base body.

What are the advantages of diamond grinding tools?

Diamonds are a carbon modification that is characterised by one property in particular: It is the hardest naturally occurring substance. This means that diamond grinding tools can process materials where other tools reach their limits. Wear is relatively low, meaning that diamond grinding tools can impress with a long service life.

Similar to simple sandpaper, the grain size can be customised to suit individual requirements. The diamond powder can be produced very coarsely with a grain size of 1000 micrometres or more. However, very fine variants with a diameter of 25 micrometres or less are also possible. As a rule of thumb, the harder the surface material and the finer the desired result, the finer the diamond powder used should be.

What are diamond grinding tools suitable for?

Due to their particular hardness, diamond grinding tools are in demand wherever particularly hard materials need to be processed and ground. Steel is an exception. Rotating diamond grinding tools cannot be used here as the resulting temperatures are too high. Apart from this, there are virtually no limits to the range of applications for the tools:

- Thermosetting plastics, for example with glass or carbon fibre reinforcement

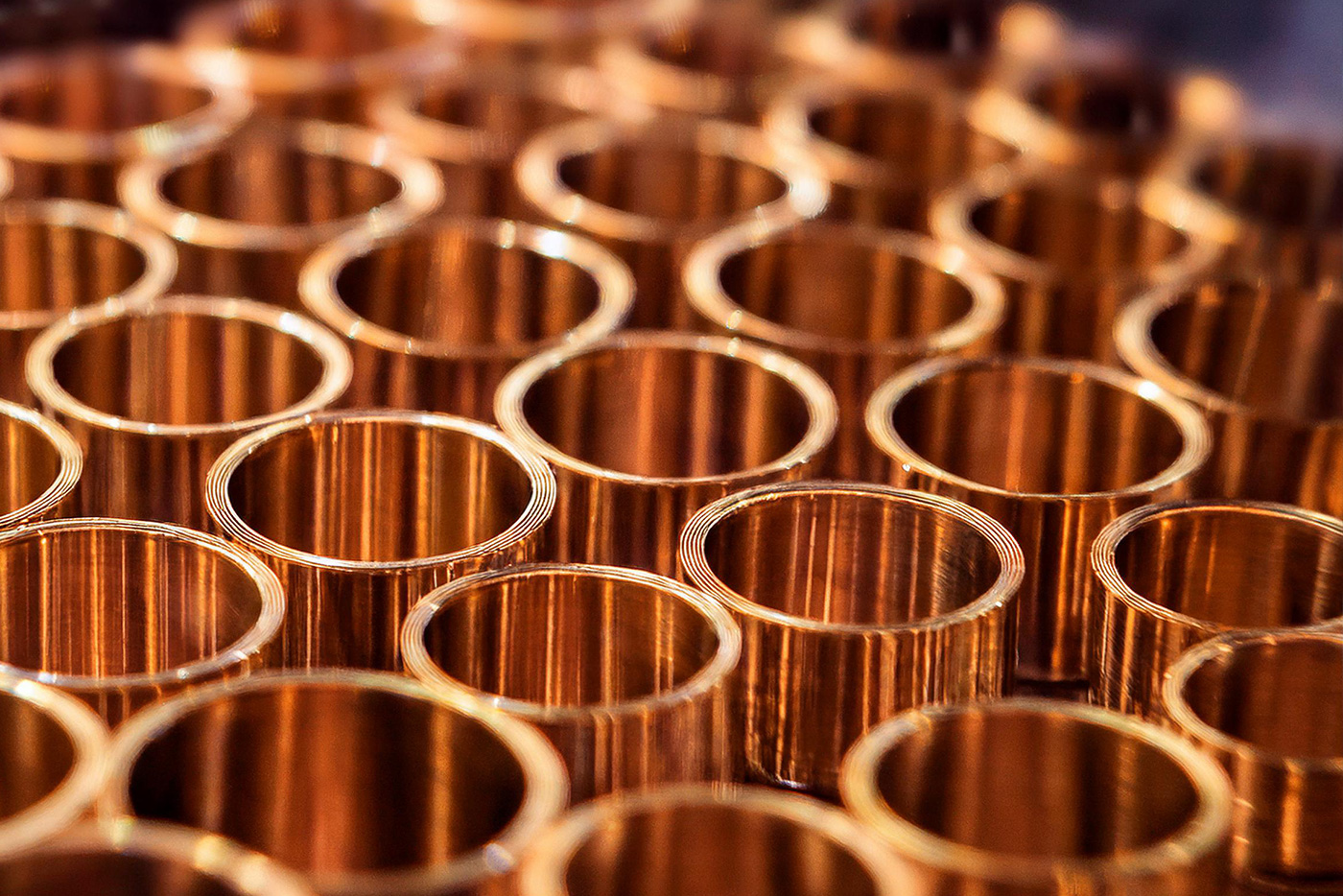

- Ferrite

- Glass

- Graphite and electrocarbon

- Grey and ductile cast iron

- Carbide

- Nickel- or titanium-based superalloys

- Technical ceramics

- Wear-resistant coatings (spray-on and weld-on alloys)

This makes diamond grinding tools an attractive alternative to conventional grinding tools for a wide range of industries - or even the only solution for day-to-day business alongside CBN tools. Areas that benefit from the resistant tools include, for example

- Automotive industry and suppliers

- Energy industry

- Foundries (grey and nodular cast iron)

- Ceramics processing industry

- Plastics processing (GFK/CFK)

- Mechanical and plant engineering

- Medical technology

- Tool and mould making

- Tool industry

What needs to be considered when using diamond grinding tools?

Diamond grinding tools can achieve great things in industrial applications. To ensure that you utilise the full potential of the tools, a few aspects should be taken into account when selecting and using them.

Type of diamond powder

Grinding tools are coated with either monocrystalline or polycrystalline diamond powder. With monocrystalline industrial diamond, straight cutting edges are produced under load - the diamond grain is virtually cut into slices during grinding. This type of industrial diamond is easy and inexpensive to produce.

The production of polycrystalline diamond powder is more expensive. However, this has a clear advantage: it breaks under the stress of grinding in such a way that new sharp corners are created instead of a straight edge. This results in a kind of self-sharpening effect, which enables the long-term and particularly fine machining of even extremely hard materials.

Temperature management for diamond grinding tools

In general, care should be taken not to select cutting speeds that are too high. Although diamonds are considered to be extremely robust, they have a weak point. Above a temperature of 800° C, the material burns. If such temperatures occur during grinding, the diamond grinding tool can no longer be used. This can be remedied by using correspondingly low speeds for dry grinding or by using appropriate coolants for wet grinding.

Choice of connection

As already mentioned, diamond grinding discs are not made of pure diamond, but always consist of a combination of different materials. With electroplated bonds, the metal base body is coated with a layer of diamond grains. These grinding discs are more cost-effective, as the single-layer coating can always be renewed as soon as it has worn off. Diamond grinding tools based on a synthetic resin or metal bond work differently. Here, the abrasive coating is composed of diamond grains, bond and fillers and pressed tightly. This coating is not easy to replace, but is highly wear-resistant and optimised to meet the requirements.

Robust helpers for industry

Diamond grinding tools are indispensable when it comes to processing really hard-wearing surfaces and materials. As a highly hard cutting material, diamond can impress where conventional grinding tools have to give up. And thanks to their durability and the various manufacturing processes, diamond grinding tools are often a good long-term alternative whose costs are quickly amortised and whose results are permanently convincing.