Surface coating

Optimised metal powder solutions for Durable and efficient coatings - Precision and quality for demanding production processes.

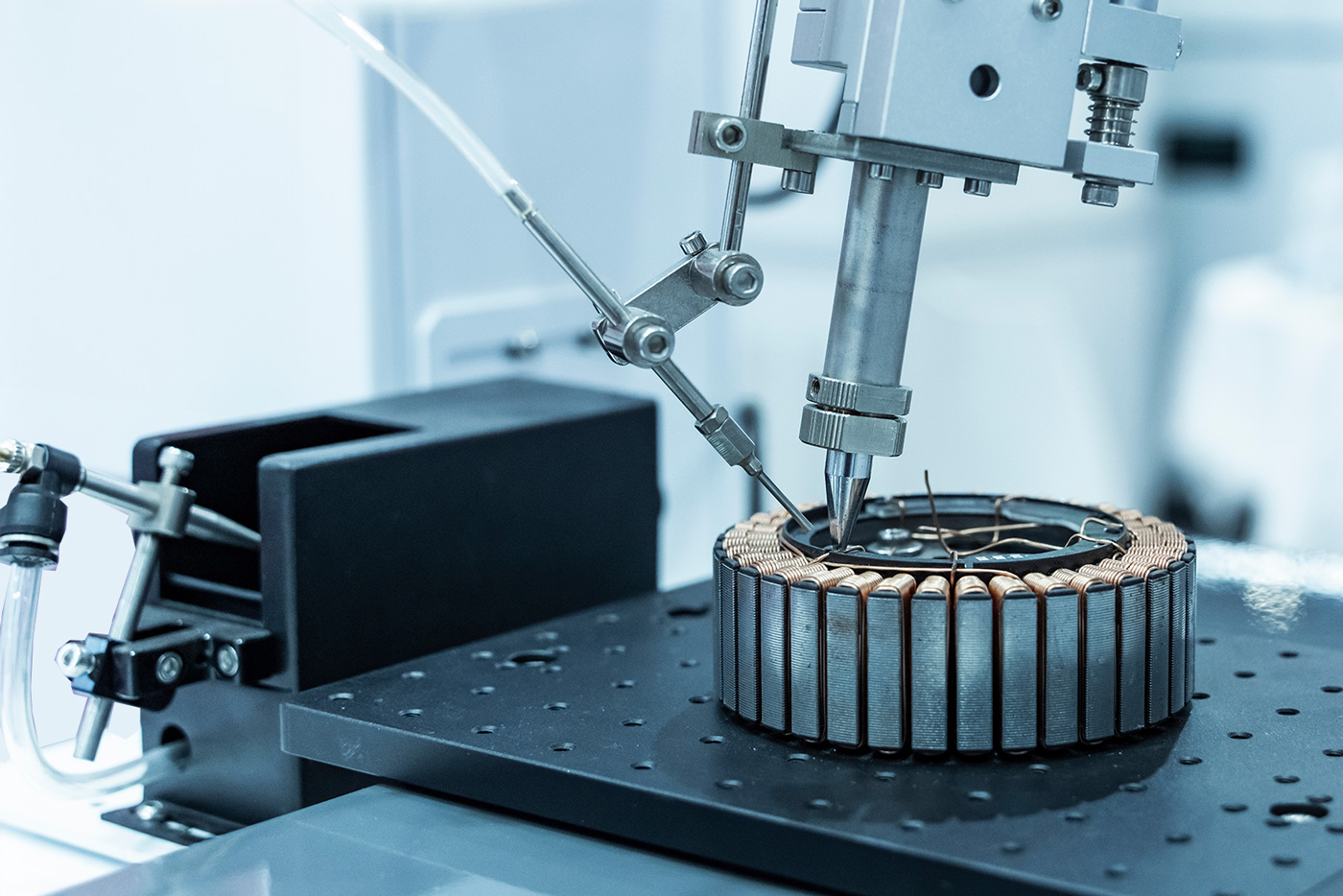

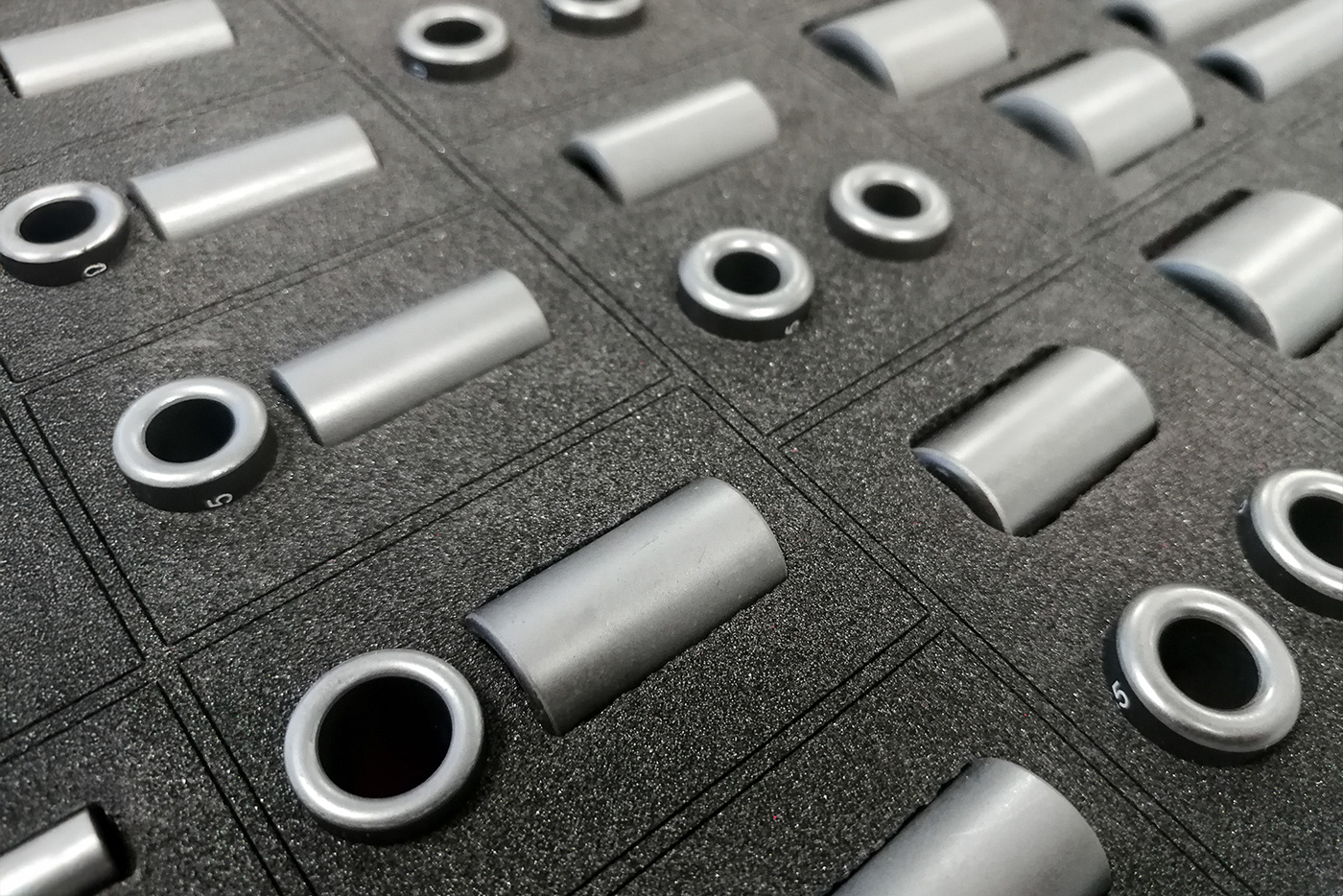

Surface coating - Precise metal powder solutions for durable coatings

Surface coatings are crucial for the protection and improvement of components in various industries. They provide wear protection, corrosion resistance and improve the aesthetic properties of products. Our metal powders for surface coatings are characterised by precise particle size distribution, high purity and excellent processability. These properties ensure uniform coatings and long-lasting results that significantly increase the service life and performance of your components.

The advantages of our metal powders for surface coatings include

- Exact particle size distribution: Ensures even and consistent coatings.

- High purity: Minimises contamination and improves the quality of the final coatings.

- Excellent workability: Enables easy application and efficient coating processes.

Our metal powders support a variety of coating processes, including powder coating, thermal spraying and laser coating, and are ideal for applications that require a precise and durable surface finish.

Suitable metal powders for surface coating

We are your reliable source for metal powders such as

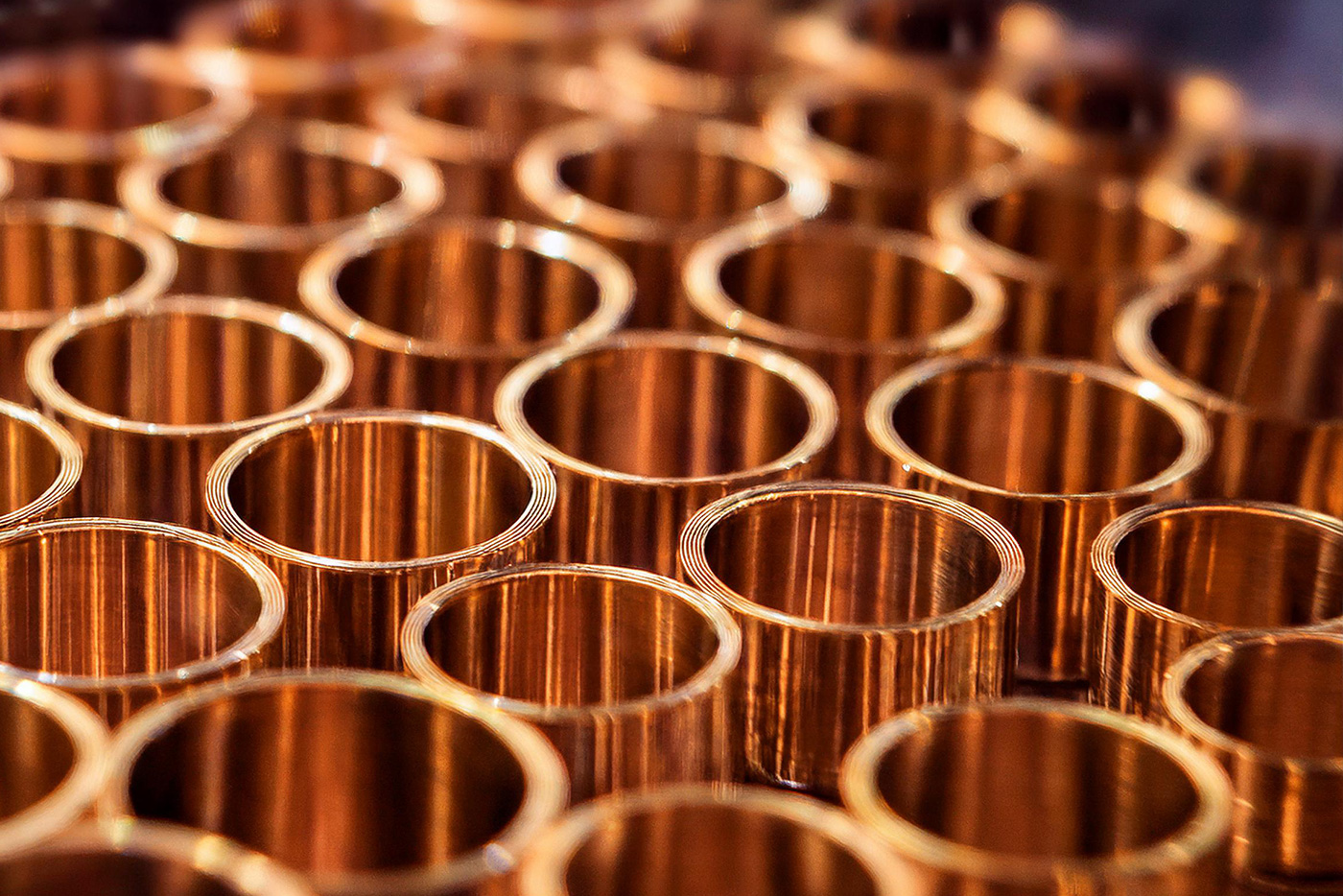

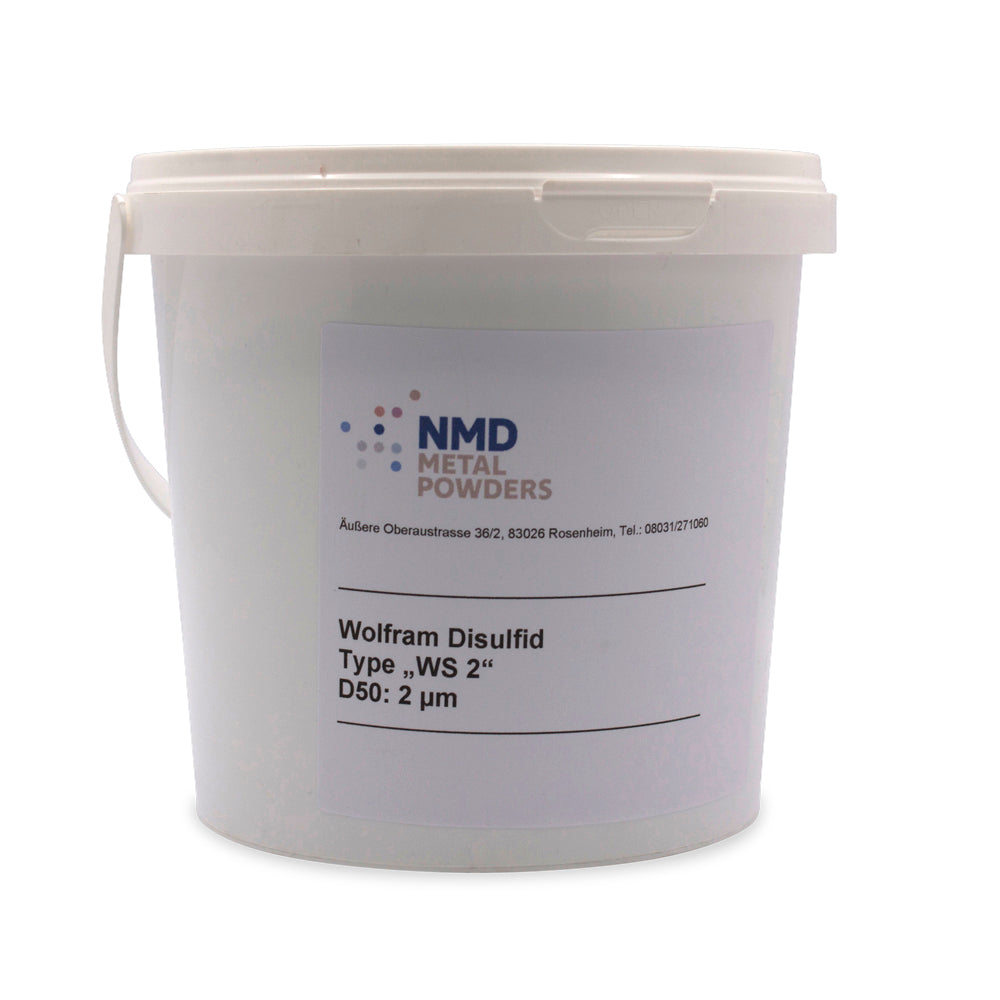

- Tungsten disulphide powder (WS2): Ideal for highly stressed components that require permanent lubrication and wear protection.

- Tungsten disulphide powder (WS5): Perfect for applications with high demands on friction reduction and wear protection.

- Bismuth sulphide: Excellent for environmentally friendly and efficient lubrication solutions.

- Molybdenum disulphide (MoS2) powder: Ideal for applications that require high temperature resistance and friction reduction.

- Manganese sulphide (MnS) powder: Suitable for applications that combine good strength and reliable lubricity.

Customers from these industries benefit from our metal powder solutions for surface coating

Surface coatings are used in a variety of industries, including

- Automotive industry: Improving the durability and appearance of vehicle parts.

- Machine and tool construction: Protection of tools and machine components against wear and corrosion.

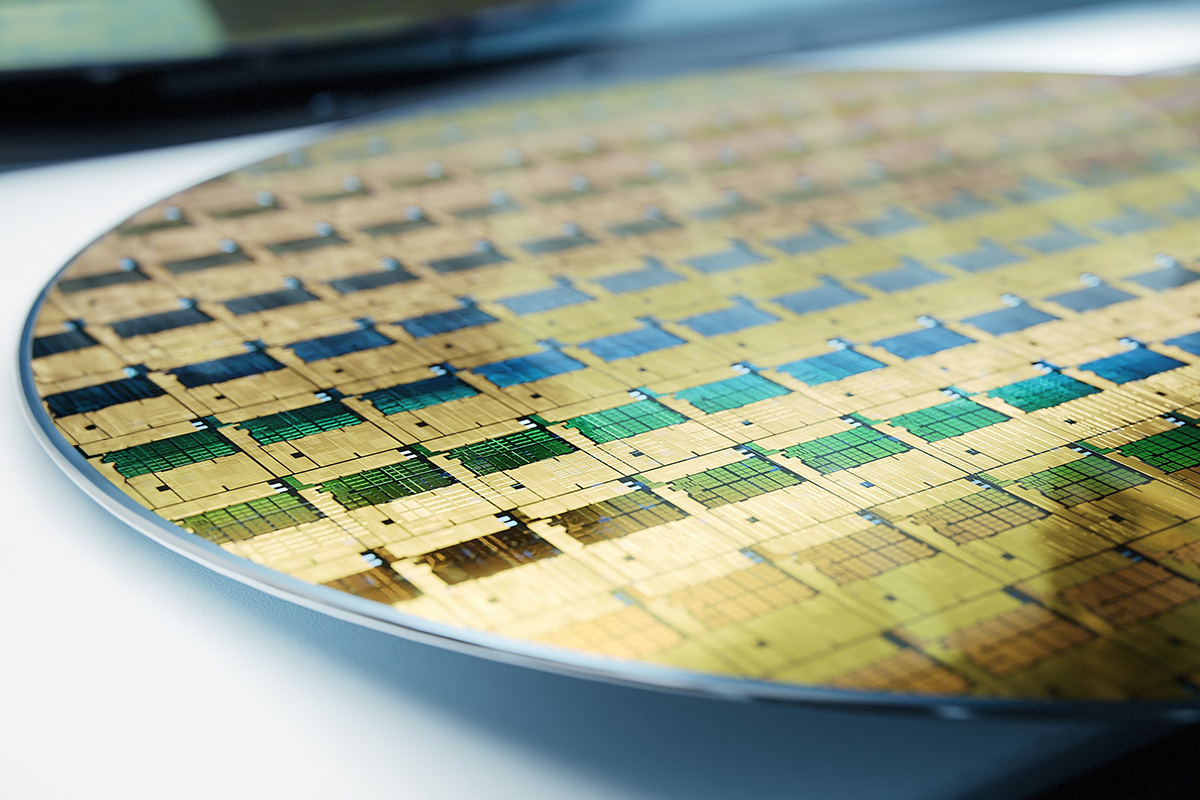

- Electrical engineering: Coating of electronic components to improve heat dissipation and corrosion resistance.

- Aerospace: Protection of aircraft parts against extreme environmental conditions and mechanical stress.

- Energy generation: Coating of components in turbines and energy systems for increased durability.

- Manufacturing industries: Improving the surface quality and service life of production systems.

- Medical technology: Coating of medical devices and implants for improved biocompatible properties.

Automotive industry

Aerospace

Machine and tool construction

Electrical engineering

Power generation

Manufacturing industries

Why NMD Metalpowders?

The quality of the metal powder directly influences the efficiency and reliability of your surface coating processes. Low-quality powders can lead to uneven coatings, increased wear rates and a shorter service life for your components.

With NMD Metalpowders, you receive high-quality metal powders that are specially optimised for surface coatings. Our many years of expertise in the development and supply of customised powder solutions ensure consistent and reliable coating results that meet your specific requirements.

Nadine Rajner

Your contact person

The advantages of professional powder coating by NMD:

- Speed: Speed up your production processes with our fast powder procurement.

- Optimisation: Achieve higher quality at lower cost with our customised powder selection.

- Anonymity: Protect your intellectual property and strengthen your market position.

- Savings: Avoid costly bad purchases. Maximise your profits with our expertise.

Machines run smoothly

because you have the right powder.

Consistently high quality

for your products because you can rely on our global supply chains.

Serenity and security

in your work, because you have us at your side as your partner.

Metal powder for surface coating

Not found your metal powder?

No problem! If your specific metal powder for surface coating is not listed here, we are guaranteed to find the right solution for your requirements.

Do you have any questions?

Contact us for individual advice or our customer service on weekdays from 09:00 to 16:00.