Main Menu

Metal powder

High quality Zirconium powder type 1 CL3 with fine particle distribution, ideal for pyrotechnics, precision applications and highly reactive processes.

because you have the right powder.

for your products because you can rely on our global supply chains.

in your work, because you have us at your side as your partner.

The Zirconium powder type 1 CL3 from NMD Metalpowders is a high-quality metal powder that has been specially developed for demanding industrial applications. With its fine particle structure and exceptional material properties, it is particularly suitable for precise and highly reactive processes. CL3 is characterised by its chemical stability, high purity and controlled reactivity, which make it indispensable for a wide range of industries.

The fine particle distribution of CL3 ensures even processing and consistent results in a wide range of manufacturing processes. These properties make it ideal for applications in pyrotechnics, additive manufacturing and surface finishing.

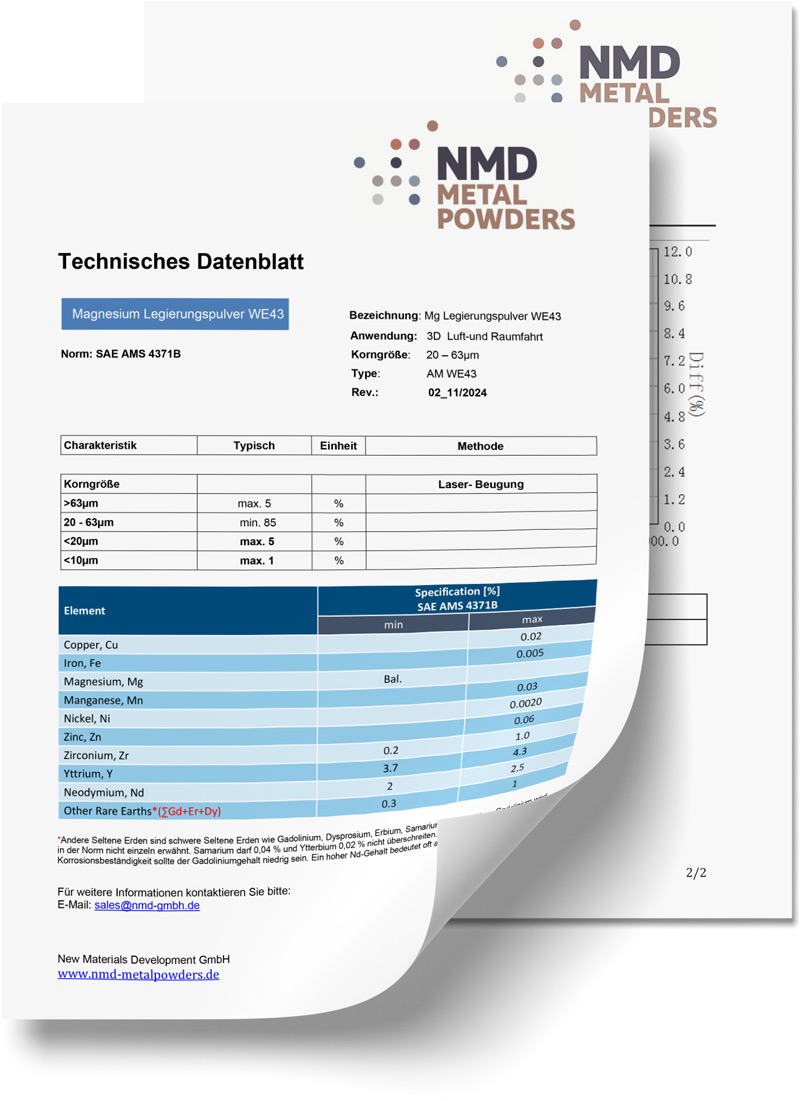

These technical specifications guarantee high process stability and the adaptability of the powder to special requirements.

Type 1 zirconium powder CL3 is known for its high reactivity and is frequently used in pyrotechnics. Due to its fine particle size and even distribution, it produces intense lighting effects and enables controlled explosions. These properties make it an indispensable material for fireworks, signalling lights and ignition systems.

In addition, CL3 is ideal for applications where a fast and consistent response is required. This controlled reactivity is particularly beneficial in safety-critical areas as it delivers reliable and predictable results.

In additive manufacturing, CL3 impresses with its fine particle structure, which enables precise layer formation. The powder is used to produce complex components with high density and strength. It enables lightweight but robust components, particularly in the aerospace and automotive industries.

The use of CL3 in 3D printing offers designers and engineers the opportunity to develop innovative geometries that cannot be realised using conventional manufacturing methods. This opens up new possibilities for the production of prototypes, medical implants and specialised components.

The uniform particle distribution of CL3 zirconium powder makes it the ideal choice for the production of precision components. These are used in aerospace, mechanical engineering and medical technology. CL3 ensures components that remain reliable even under high mechanical loads and extreme temperatures.

CL3 is ideal for coatings that improve the wear protection and corrosion resistance of components. These high-quality coatings are frequently used in electronics, the automotive industry and for specialised tools. The fine structure of the powder ensures uniform layer formation and significantly improves the service life of the coated surfaces.

Thanks to its chemical stability and high reactivity, CL3 is an indispensable material for sintering technology. It enables the production of components with high density and strength, which are used in power generation, aviation and other industries.

Zirconium powder type 1 CL3 is used in power generation, particularly in the manufacture of components for fuel cells and other high-performance systems. Its high chemical stability and corrosion resistance make it an important material in systems that are operated in aggressive environments.

The zirconium powder type 1 CL3 offers numerous advantages:

The zirconium powder type 1 CL3 contributes to resource conservation and energy efficiency thanks to its optimised particle distribution. It minimises material losses and enables sustainable production, especially in additive manufacturing and surface coatings. Its durability and versatility support companies in implementing environmentally friendly production processes.

The Zirconium powder type 1 CL3 from NMD Metalpowders combines excellent chemical stability, controlled reactivity and precise particle distribution. It is the ideal choice for demanding applications that require maximum precision and efficiency.

Whether in pyrotechnics, additive manufacturing, surface coatings or energy generation - CL3 impresses with its reliability, quality and sustainable efficiency. Choose CL3 to optimise your production processes and take your products to a new level.

Contact us for individual advice or our customer service on weekdays from 09:00 to 16:00.

"*" indicates required fields

Contact us for individual advice or our customer service on weekdays from 09:00 to 16:00.

"*" indicates required fields