Metal sulphides have a firm place in various branches of industry. If you are new to metal sulphides or are considering whether sulphur compounds are an option for your company: Here are five facts about metal sulphides to help you decide and take the next steps.

A true all-rounder

Metal sulphides are known to be particularly useful in analytical chemistry for the separation of cations. However, metal sulphides can also achieve a great deal outside the classic laboratory situation. Their special properties and numerous variants make them true all-rounders with a wide range of possibilities.

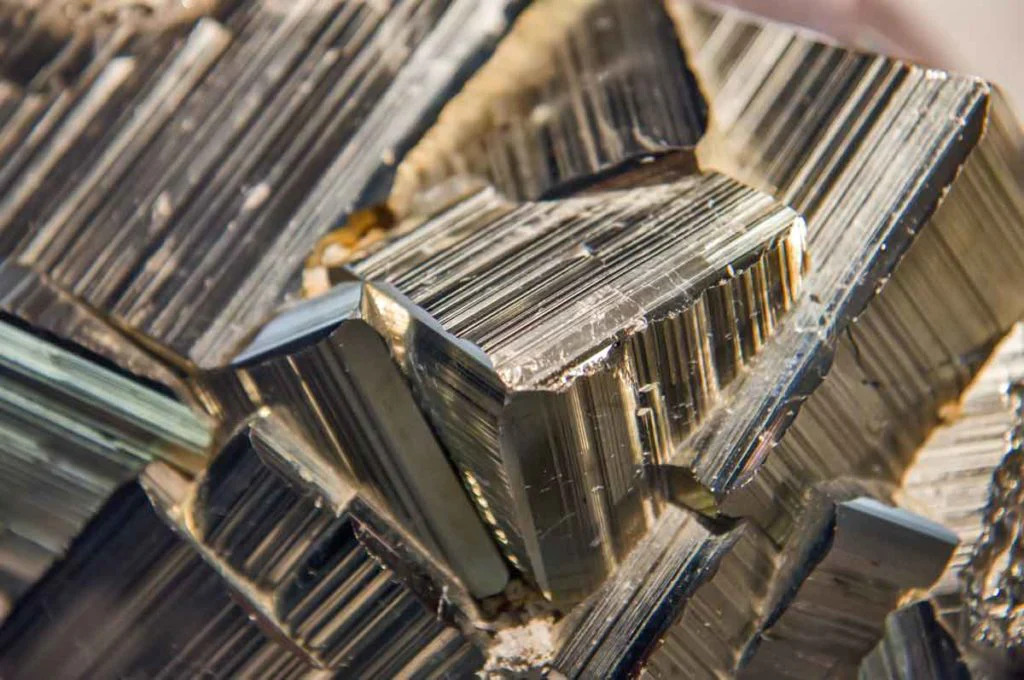

Number 1: Metal sulphides occur in nature

Sulphides and therefore also metal sulphides officially belong to the group of salts. These are always metal-sulphur compounds in a wide variety of forms. These compounds can be produced in the laboratory - but some can also be found in nature. Probably one of the best-known representatives is pyrite, a modification of iron(II) disulphide. The chemical composition of iron and sulphur in a ratio of 1:2 is also known as fool's gold. Molybdenum(IV) sulphide also occurs in nature in the form of the mineral molybdenite. Other metal sulphides such as tin(IV) sulphide are rather rare and are mainly produced industrially by processing the raw materials using the appropriate chemical reactions.

Number 2: Metal sulphides have a low solubility

Metal sulphides have the property of being difficult to dissolve. At the same time, sulphides are highly reactive with heavy metals. This combination of chemical properties makes them the ideal choice for wastewater treatment. The heavy metal ions react with the sulphur to form the sparingly soluble metal sulphides, which do not further contaminate the water. These are then simply removed and processed in the form of the resulting metal sulphide sludge. In this way, valuable resources can be recovered from the industry, which is beneficial both economically and in terms of environmental protection. And the resulting end products can in turn be used by other companies for their products and processes - a win-win situation.

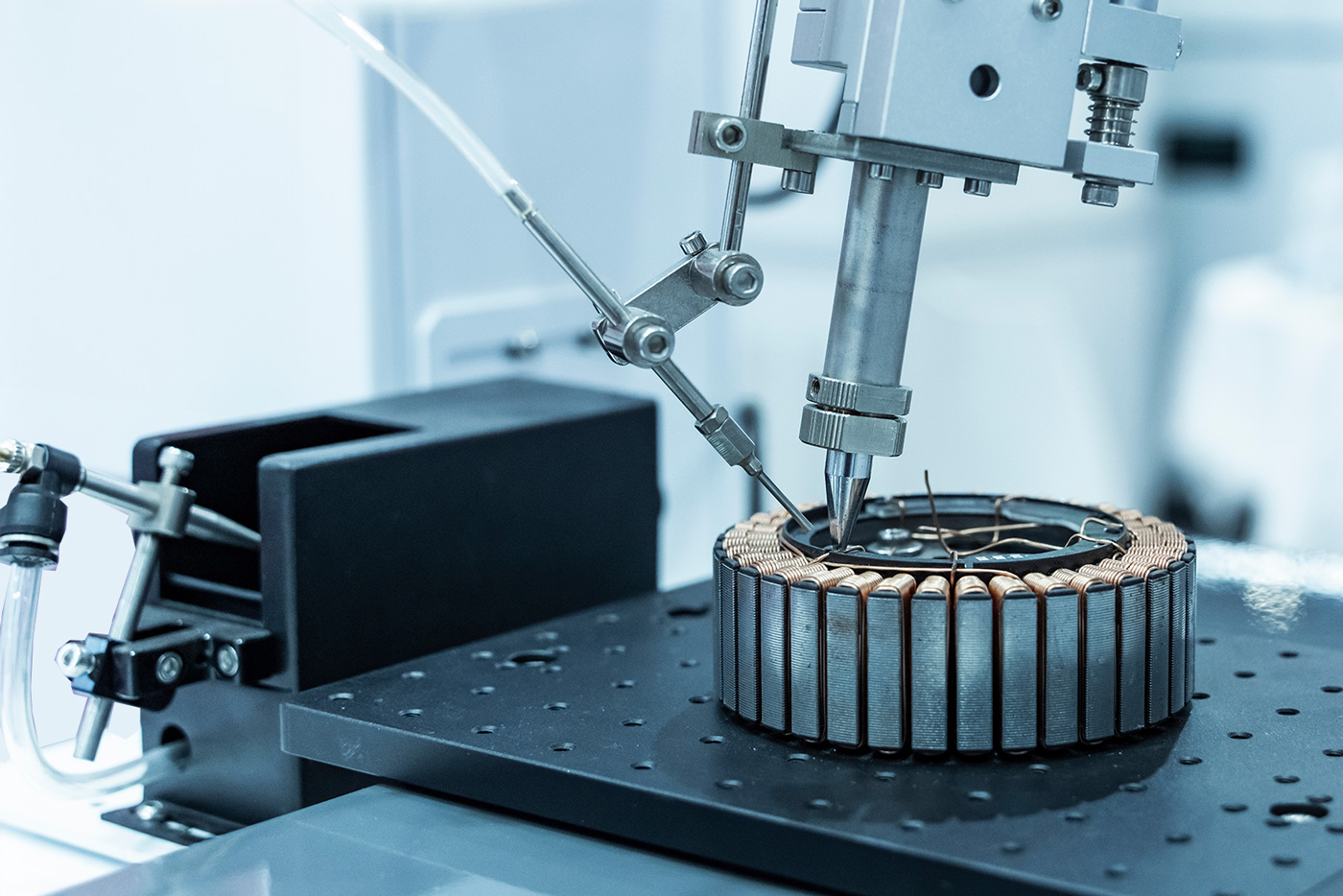

Number 3: Metal sulphides are an ideal lubricant

Metal sulphides in fine powder form are used in industry as lubricants. The particle size of the grains is usually between 1 and 100 micrometres. Molybdenum disulphide, for example, is added to lubricating oils and greases. The additive improves the lubricating effect. As a result, machine components such as engines and centrifuges have a longer service life. In addition, the risk of damage in the event of sudden oil loss is drastically reduced. In addition to mixing with solid and liquid lubricants, metal sulphides are also used in bonding. In this process for treating metal surfaces, corrosion protection is created by using the appropriate metal sulphide. The areas of application in which they are in demand as lubricants include

- Automotive

- Aircraft manufacturing (turbines)

- High temperature applications

- Laboratory technology (ultracentrifuges)

As functional additives, they are not only used in sintered metals, but also in plastics and batteries.

Number 4: Metal sulphides reduce the manufacturing and maintenance costs of sintered parts

Lubricating and oiling complex or difficult-to-access components often increases the cost and time required for maintenance - if it can be done successfully at all. By improving the lubricating effect, metal sulphides can significantly extend the necessary maintenance intervals and thus reduce running costs. The right metal sulphide can also save costs in certain manufacturing processes by simplifying work steps.

Manganese sulphide improves the machinability of sintered moulded parts, for example. If the sulphide is added to the metal powder during sintering, the finished components can be drilled, milled or turned much more easily. This means that less time is required for reworking the moulded parts. The production of large quantities in consistently high quality is no problem. Metal sulphides therefore have a firm place in powder metallurgy as a reliable partner for the best possible results.

Number 5: Metal sulphides can be individually optimised

The various metal sulphides can therefore fulfil a wide variety of tasks - and even within the respective sulphide groups, different areas of application are possible. Very fine tin(IV) sulphide can be used as a colour pigment, but can also reduce wear on stressed components. Bismuth sulphide is used as a component of fluxes for arc welding, but can also be found as a friction material in brake linings and clutch linings. Thanks to the development of multiphase metal sulphide clouds, more and more areas of application are being opened up for metal sulphides and ever better results are being achieved.

Salts for all occasions

If you are looking for new solutions for your company or ways to optimise existing production processes, it is worth taking a closer look at the topic of metal sulphides. These salts are truly multi-talented and have numerous applications. To use them successfully, you need reliable partners and suppliers who can offer you the best solution with their chemical expertise and industry knowledge. This is the only way you can really utilise the full potential of metal sulphides.