Is it running like clockwork? Then solid lubricants could have a hand in it. Anyone who has previously only relied on lubricating oils and greases will be surprised by the benefits of dry lubricants. We have summarised five good reasons for using them here.

Solid lubricants in use: a good idea?

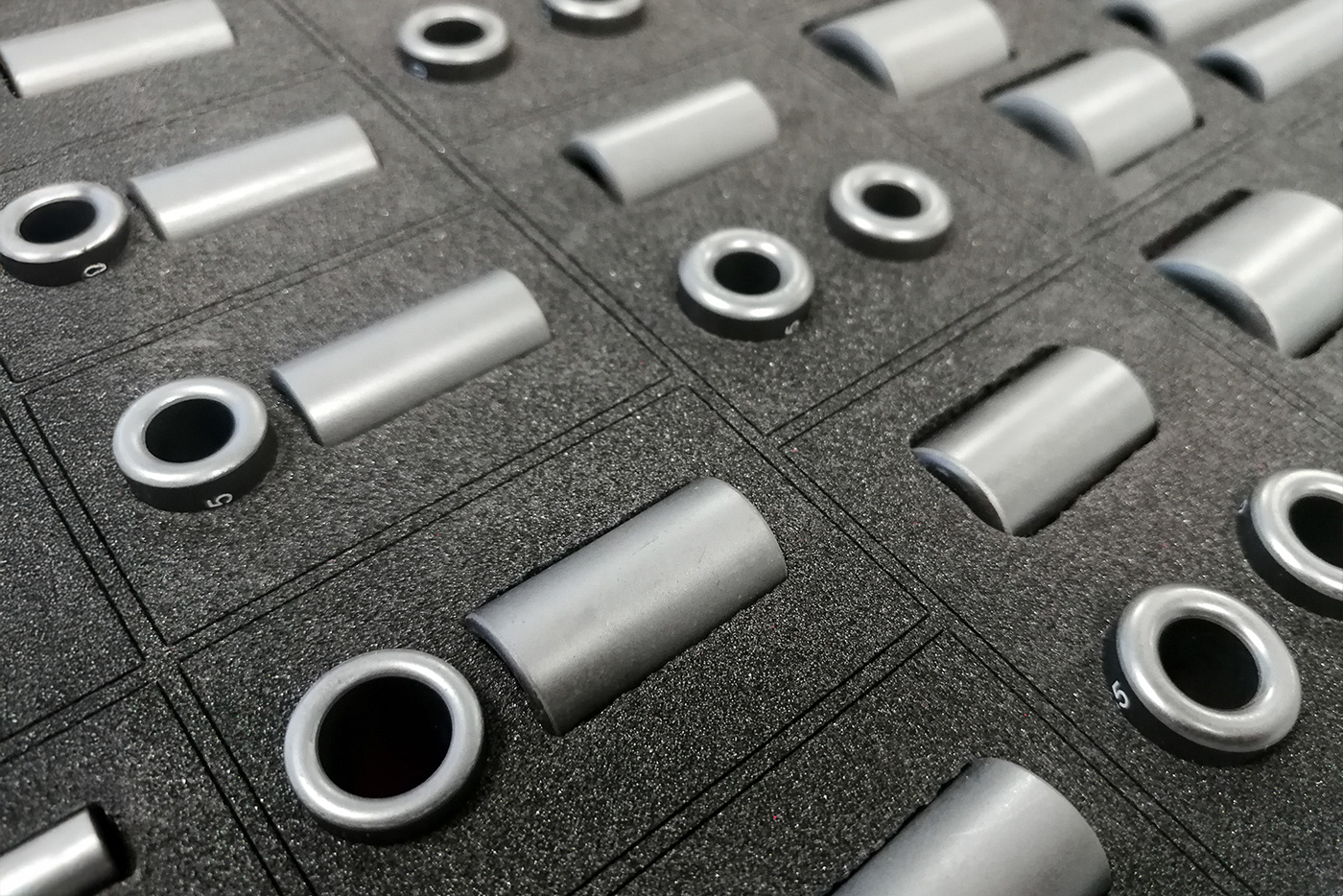

Greases and oils are the main classic lubricants used in industry and in everyday life. However, an alternative has become established in the professional sector in particular: Solid lubricants. The idea of a solid lubricant may seem unfamiliar at first glance - after all, we do not intuitively associate lubricity with small solid particles. However, whether as an additive to typical lubricating oils and greases or as a directly used release agent, there are good reasons to consider solid lubricants for a wide variety of applications.

Reason 1: High temperature resistance and robustness

Solid lubricants are particularly in demand when conventional lubricants reach their limits. Above all, use at extreme temperatures can quickly clog oils and greases and severely impair their lubricity. Depending on the composition of the solid lubricant, temperatures between -180°C and 550°C are no problem.

And other extreme conditions that cause problems for conventional lubricants are no match for the right solid lubricants. These include, for example

- High loads and low speeds (shock load)

- Vacuum

- Aggressive environmental conditions (e.g. acids or alkalis)

- Radioactive radiation

As a result, solid lubricants are not only interesting for standard applications, but are also suitable for special tasks, for example in nuclear and aerospace technology.

Reason 2: Versatile use

Solid lubricants are not only (almost) independent of external conditions in their area of application. There are also virtually no limits to where they can be used. The spectrum ranges from complex industrial applications to the hobby sector. Typical areas of application for solid lubricants include

- Gearbox

- Ball bearings, roller bearings

- Exhaust and spark plug threads (in the form of hot screw compounds)

- Engine oil

- Bullets for sporting weapons

Heavy industry, mining, the automotive sector, aerospace and more: solid lubricants have found their way into a wide variety of industries. Thanks to innovative research and development, the range of applications can be continuously expanded.

Reason 3: Individually customisable

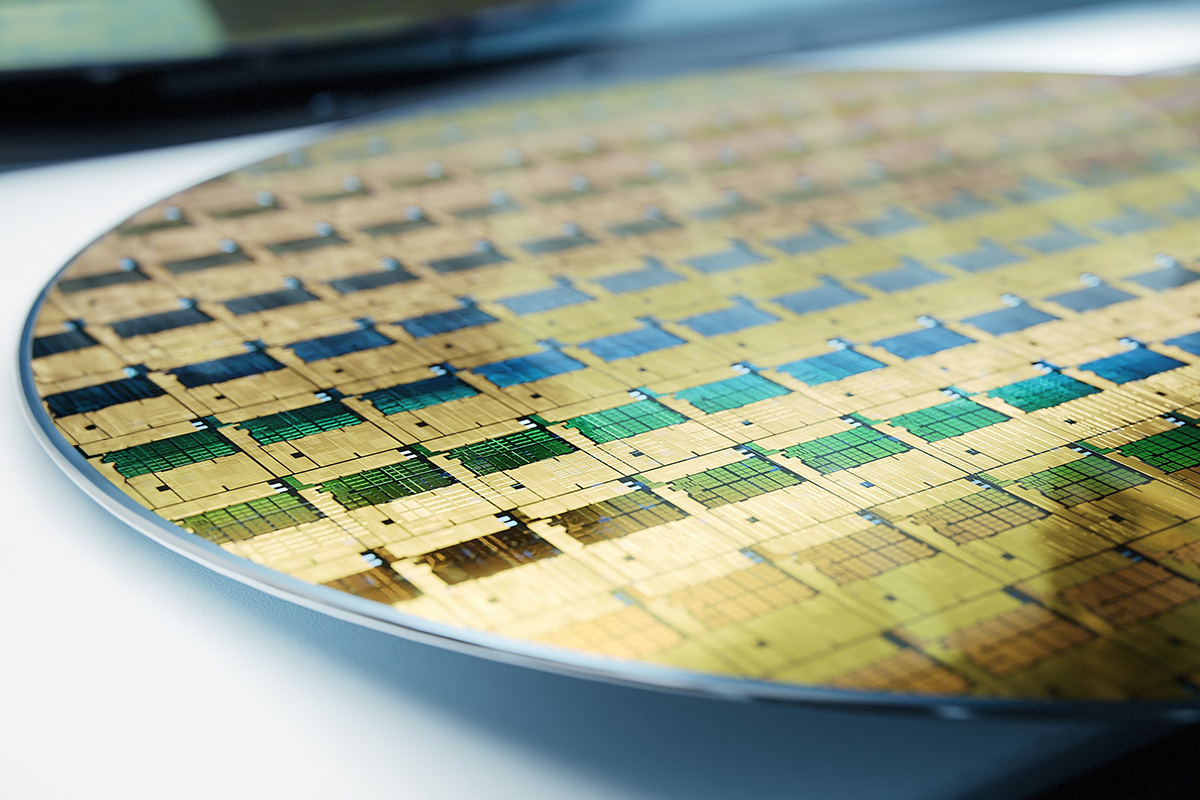

There is a large selection of solid lubricants. On the one hand, this can initially lead to excessive demands when choosing the right substance, but on the other hand it has a great advantage: the right solid lubricant can be found for every application. A variety of robust substances are used - either in pure form or as a sulphide compound. Common solid lubricants include, among others:

- Graphite

- Molybdenum disulphide

- Tungsten disulphide

- PTFE (Teflon)

- Ceramics

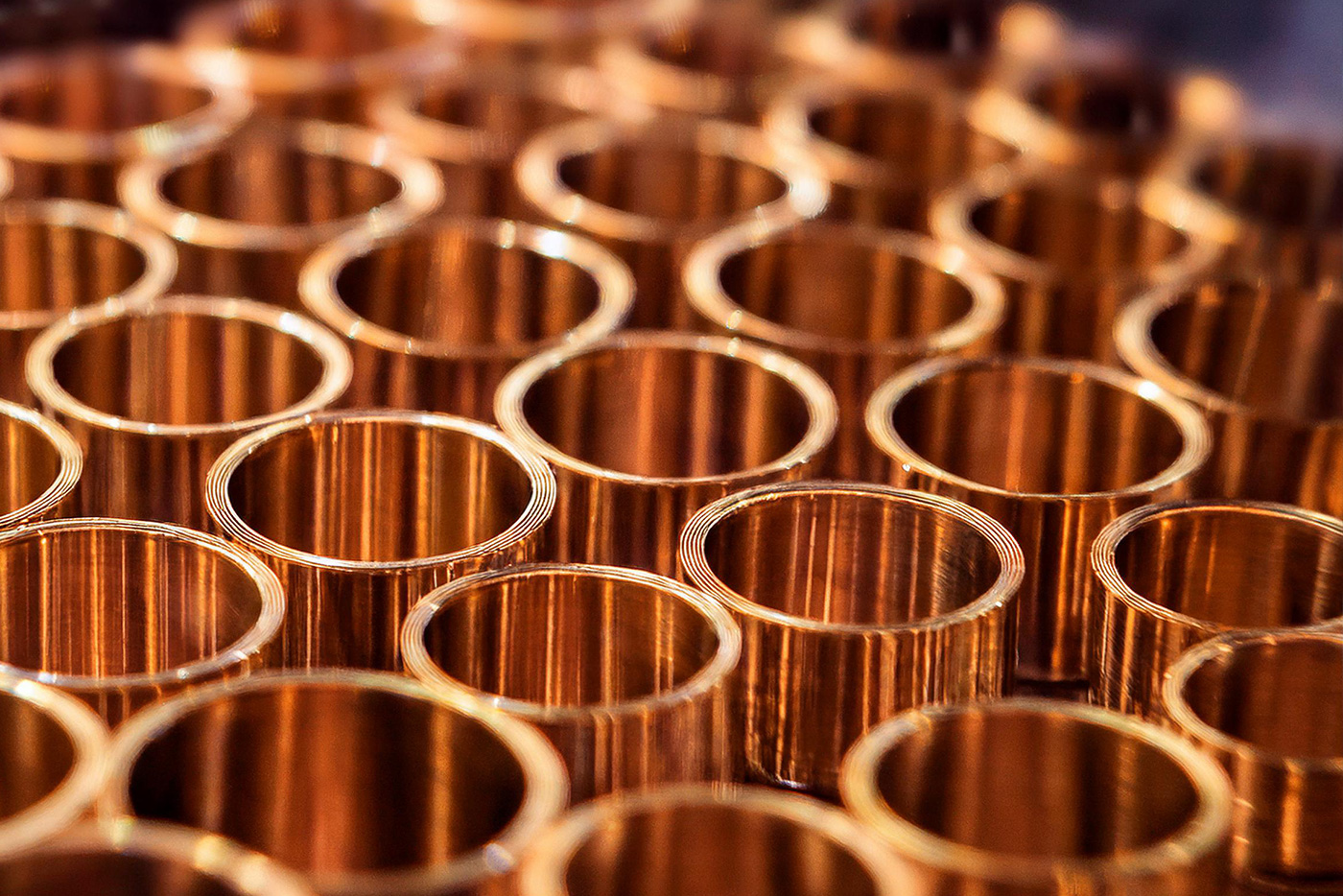

- Soft metals (aluminium, copper, lead, tin)

- Precious metals (gold, silver, platinum)

The materials differ in terms of particle size and structure, corrosion properties, sliding properties, temperature resistance and other characteristics. The right combination of material and lubricants (both in fluid and solid form) is essential for successful use.

Reason 4: Long-term cost savings

The use of solid lubricants has numerous advantages - especially when it comes to the service life and maintenance requirements of machines and components. Adding a solid lubricant to lubricating oils and greases initially means an additional investment. The improved lubricity, both in normal operation and especially during emergency lubrication, significantly reduces wear. Downtimes are minimised and productivity is increased. In general, components lubricated with solid lubricants have a longer service life and can withstand loads for longer. This means that the costs for the possibly more expensive lubricants are amortised in the medium and long term.

Reason 5: Simple application

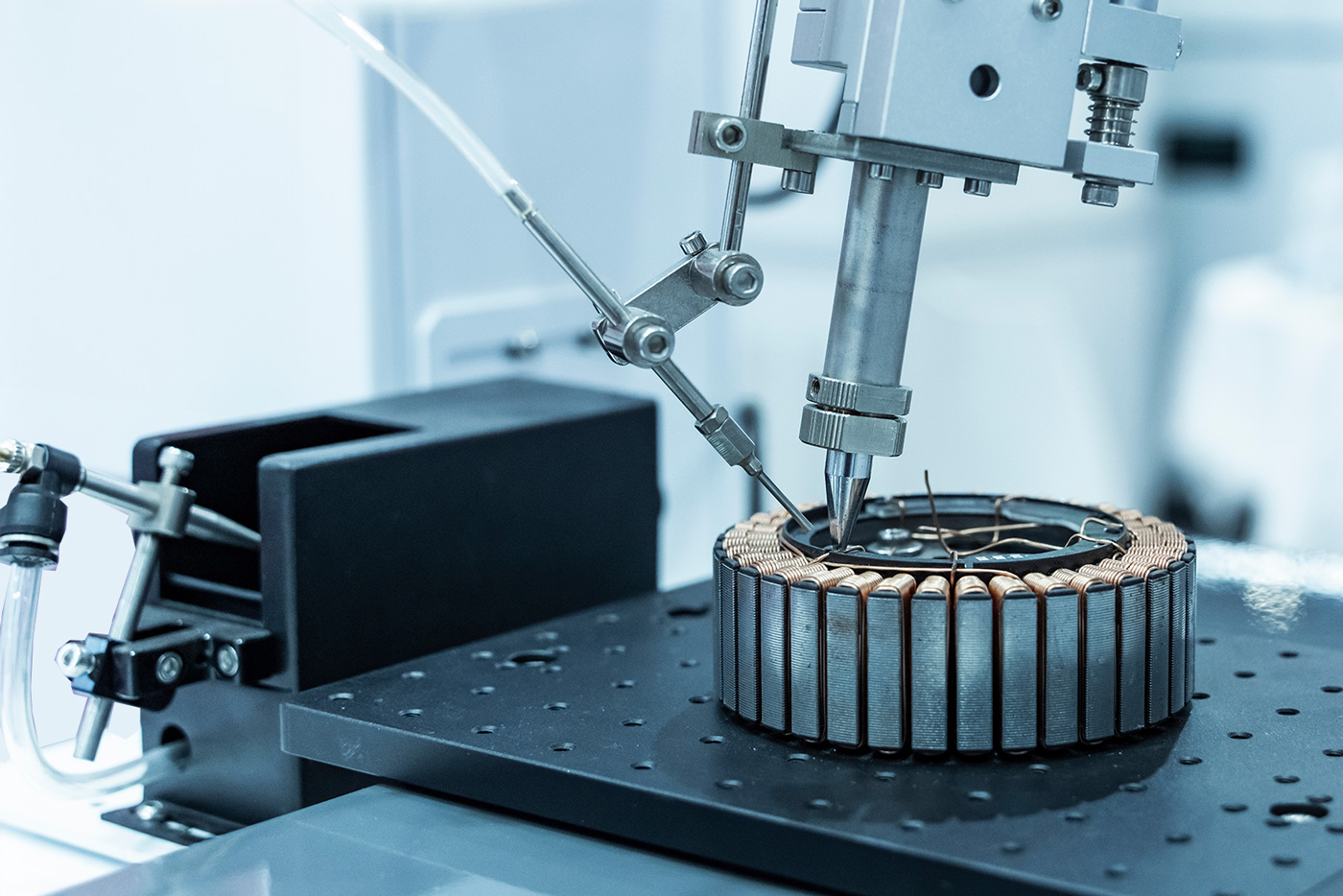

Another special feature of solid lubricants is that they can be bonded directly to the material. Solid lubricant plain bearings, for example, are directly provided with an alloy of a suitable material that gives the component excellent sliding properties. Components like these are practically self-lubricating. No oil or grease needs to be added. Solid lubricants are a simple and reliable alternative, especially for complex components that are difficult to reach or whose lubrication would be extremely costly and time-consuming.

Solid lubricants for industry and everyday life

Even if the drop of oil for the squeaky garden gate or the bicycle chain fulfils its purpose at home: For more complex applications, extreme conditions or the desire for greater efficiency and productivity, it is worth taking a closer look at solid lubricants. As an alternative or supplement, they can develop great potential - and integration usually does not require too many changes.