Metal powder and the automotive industry are now inextricably linked. A wide variety of applications and processes rely on metal in powder form. This article will show you where they are used and what advantages this can have.

Industry in transition

The first cars no longer have much in common with today's modern motor vehicles. Just as the requirements for cars and their equipment have changed, new paths have also been taken in the area of production. The automotive industry is changing and is far from having reached the end of its development - and metal powders are contributing to the success and innovative strength of the industry in various ways.

Where are metal powders used in the automotive industry?

Metal powders are more common in the automotive industry than might be apparent at first glance. Three areas of application are particularly important: sintering, soldering and additive manufacturing.

1. sintering in automotive manufacturing

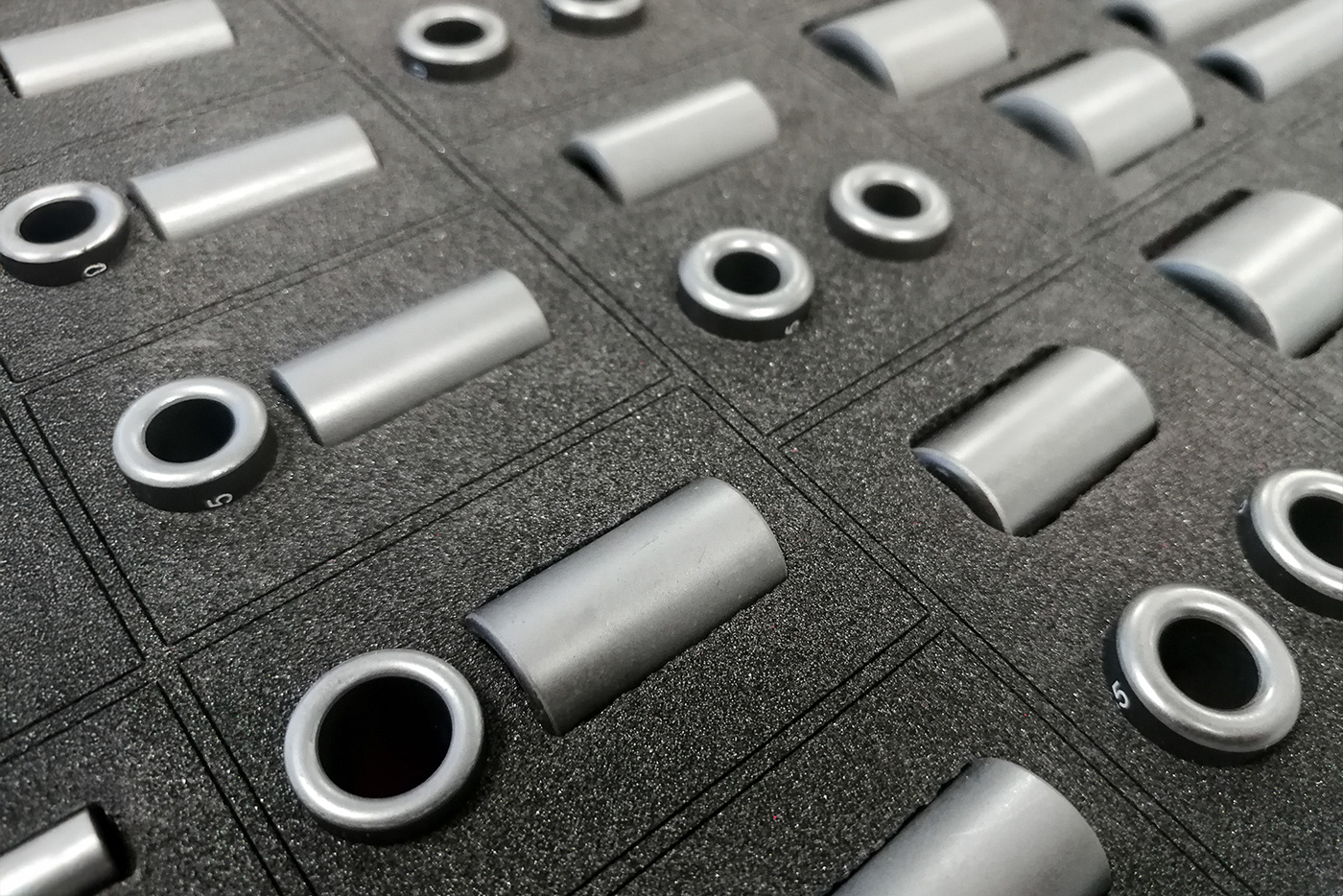

Car manufacturers have been using metal powder for a long time. Sintered or pressed vehicle parts can be found in almost every classic car. Complex moulds and components, such as those found in engines, can be reliably produced in large quantities using sintering. The high dimensional accuracy, reliable reproducibility and not least the lower weight compared to solid components have made sintering and therefore the use of metal powder practically unnecessary in the automotive industry. And sintered metal powder is also used for supposedly simple parts such as friction and brake linings.

These metal powders are suitable for sintering, among other things:

- Steel, stainless steel

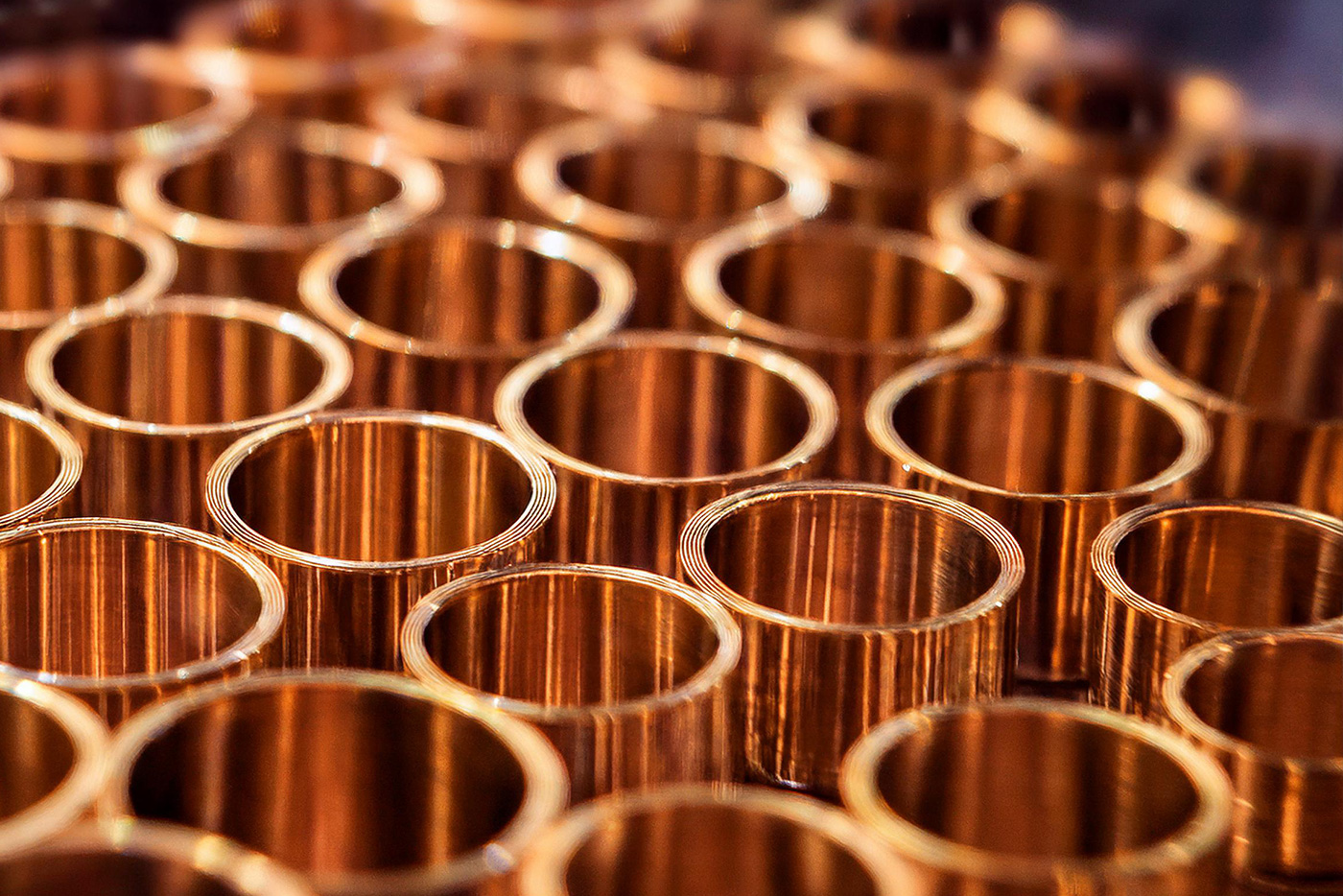

- Bronze, copper

- Aluminium, magnesium

- Titanium

- Minerals

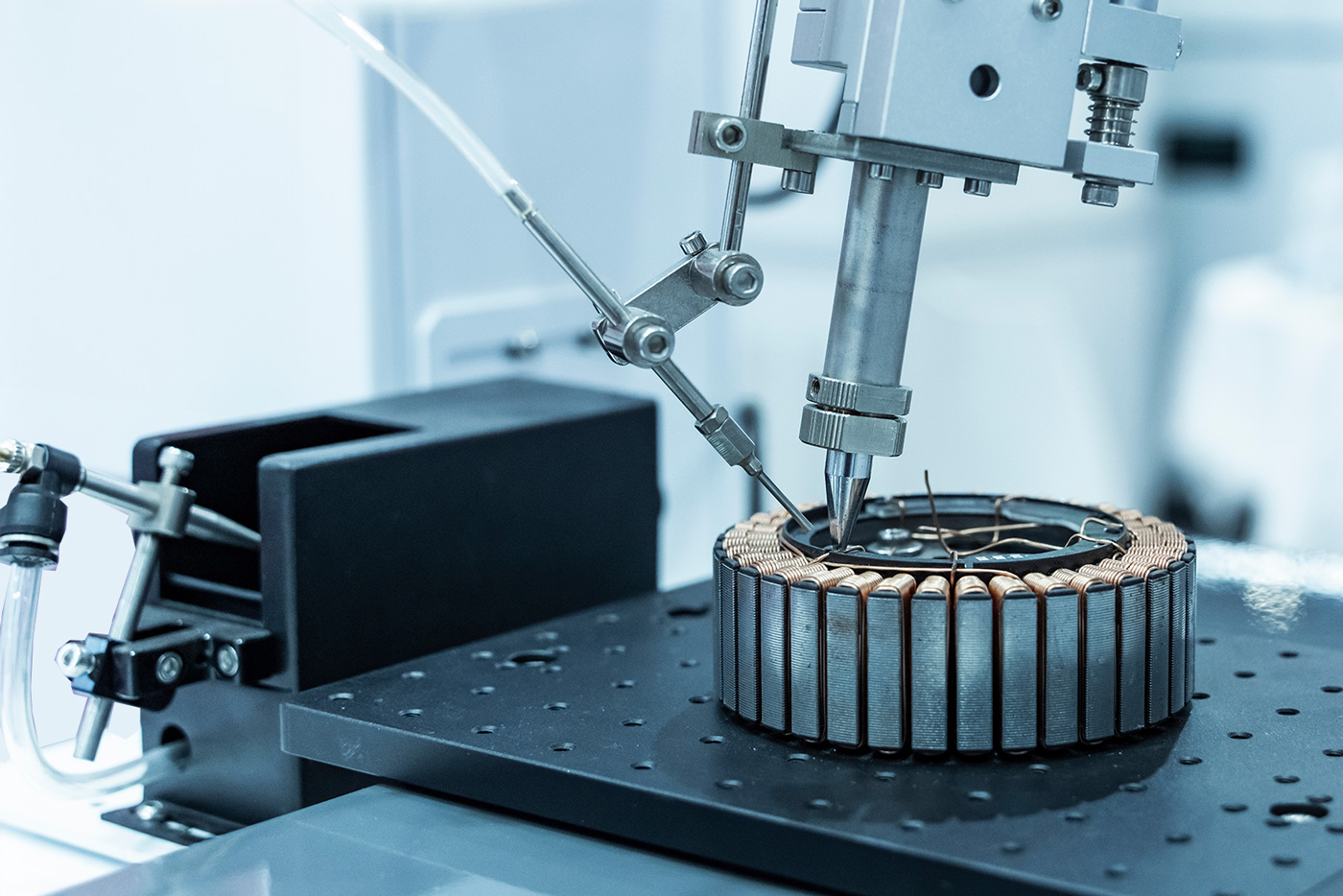

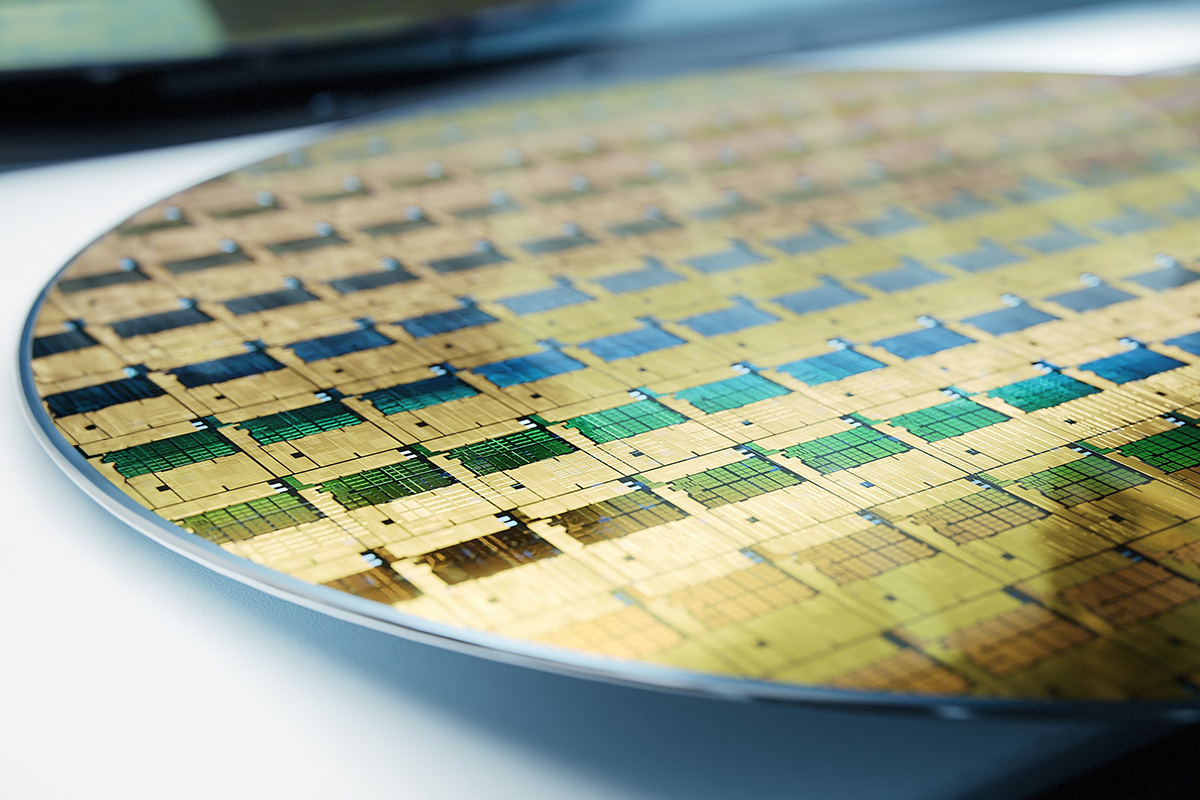

2. soldering in the automotive industry

In addition to the main components in motor vehicles, more than ever before, small-scale work is also part of everyday life in the automotive industry. In particular, the ever-increasing proportion of complex technology requires filigree work. For example, metal powders are used for soft soldering at low temperatures in order to produce the necessary circuit boards and computer chips as part of surface-mounted technology.

But brazing is also used on the car itself. Brazing at high temperatures is used on the radiator of air conditioning systems, among other things. The advantages of soldering powder are obvious. In powder or paste form, the soldering metal is easier to dose and handle. Ideally, the soldering process can even be automated. Metal powder thus saves time, money and resources in the automotive industry.

These metal powders are suitable for brazing, among other things:

- Various aluminium alloys with silicon or stainless steel

- Metal powder with very low oxygen content and narrow particle size distribution

3. additive manufacturing in the automotive industry

The automotive industry is often regarded as a pioneer when it comes to innovation. It is therefore no wonder that new processes are already being tested here as part of Industry 4.0. Specifically, 3D printing and additive manufacturing are becoming increasingly important. To date, metallic 3D printing has mainly been profitable in the field of research and development. However, it is also worthwhile for small quantities of certain components such as spare parts or customised fittings in the luxury segment. The process is not yet worthwhile for large-scale production. However, the development of prototypes and the testing of new ideas can be realised much more easily, quickly and cost-effectively with additive manufacturing than with conventional methods.

These metal powders are suitable for additive manufacturing:

- Nickel, steel, titanium, copper, aluminium, magnesium in pure form or as an alloy

- Stainless steel

4. other areas of application

In addition to the three main areas, metal powders are also used in other areas of the automotive industry. For example, metal powders are used as solid lubricants in gearboxes, usually in combination with the corresponding sintering process. Thermal coatings can also be applied using the appropriate metal powder.

Metal powder and the automotive industry: top performance for today and tomorrow

Metal powders are already an integral part of the automotive industry - and their potential has not yet been exhausted. New technologies such as electric and hybrid cars require new production processes and innovative components that can be realised cost-effectively and reliably with the help of metal powders. The automotive industry can also score points with metal powders when it comes to sustainability: After all, powder processing saves on materials and energy compared to solid processing. In this way, companies can use today's knowledge to shape the future and combine innovation with environmental protection.