Globalised supply chains have shaped the metal industry for decades. However, few sectors feel the effects of geopolitical tensions, raw material shortages and transport disruptions as directly as the procurement of metal powders. For manufacturers, suppliers and technology companies, it is therefore becoming increasingly important to understand global interdependencies and to future-proof their own supply chains.

1. Geopolitical developments are changing the commodities market

Whether trade conflicts, export restrictions or regional subsidy freezes: political decisions today have a direct impact on the availability of key metals. Examples include the recent Chinese export restrictions on strategic raw materials such as Germanium or Gallium or the unstable situation in resource-rich producing countries such as Myanmar.

For companies, this means:

- Volatile prices for critical and rare metals

- Fluctuating delivery times and temporary unavailability

- Increased planning uncertainty in production and development

Anyone who uses metal powder as the basis for their applications (3D printing, Coating, etc.) must take these political conditions into account more than ever before.

2. Logistics & Transport: A fragile system

In addition to geopolitical factors, a look at logistics also reveals that global transport has become more vulnerable.

These include, among others:

- Container capacity bottlenecks

- Delays at ports and borders

- Rising transport costs due to energy prices

- Risks due to natural disasters or disruptions on sea routes

For metal powders, which often need to be transported in specialised packaging, under protective atmosphere or within specific temperature ranges, any delay can have a direct impact on quality and delivery capability.

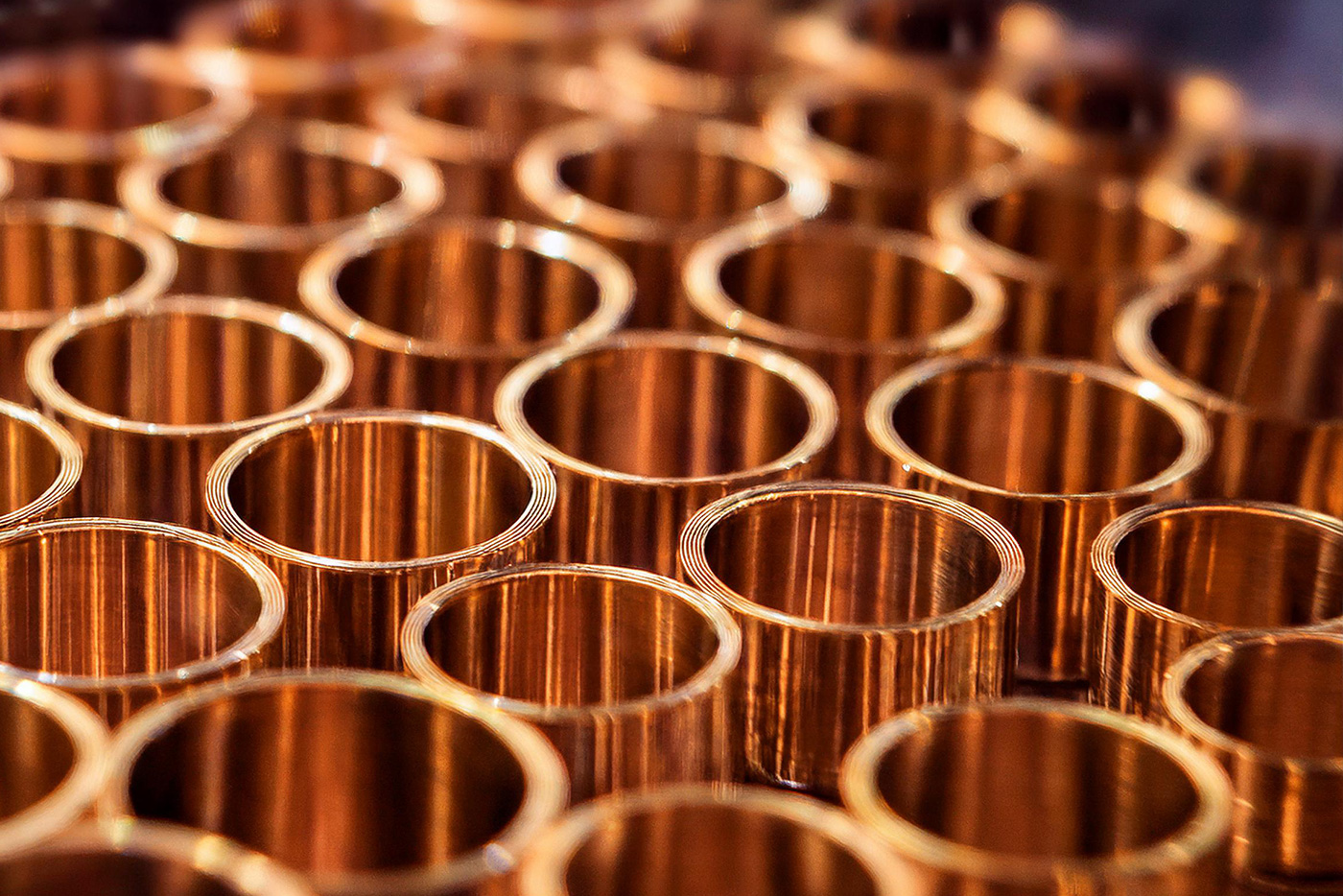

3. Dependence on raw materials and production risks

Metal powders are produced from primary raw materials, the extraction of which is often dominated by just a few countries. This high concentration leads to structural dependencies.

Risks include:

- supply bottlenecks through political intervention

- quality fluctuations, if alternative sources must be used

- Rising production costs due to energy-intensive refining processes

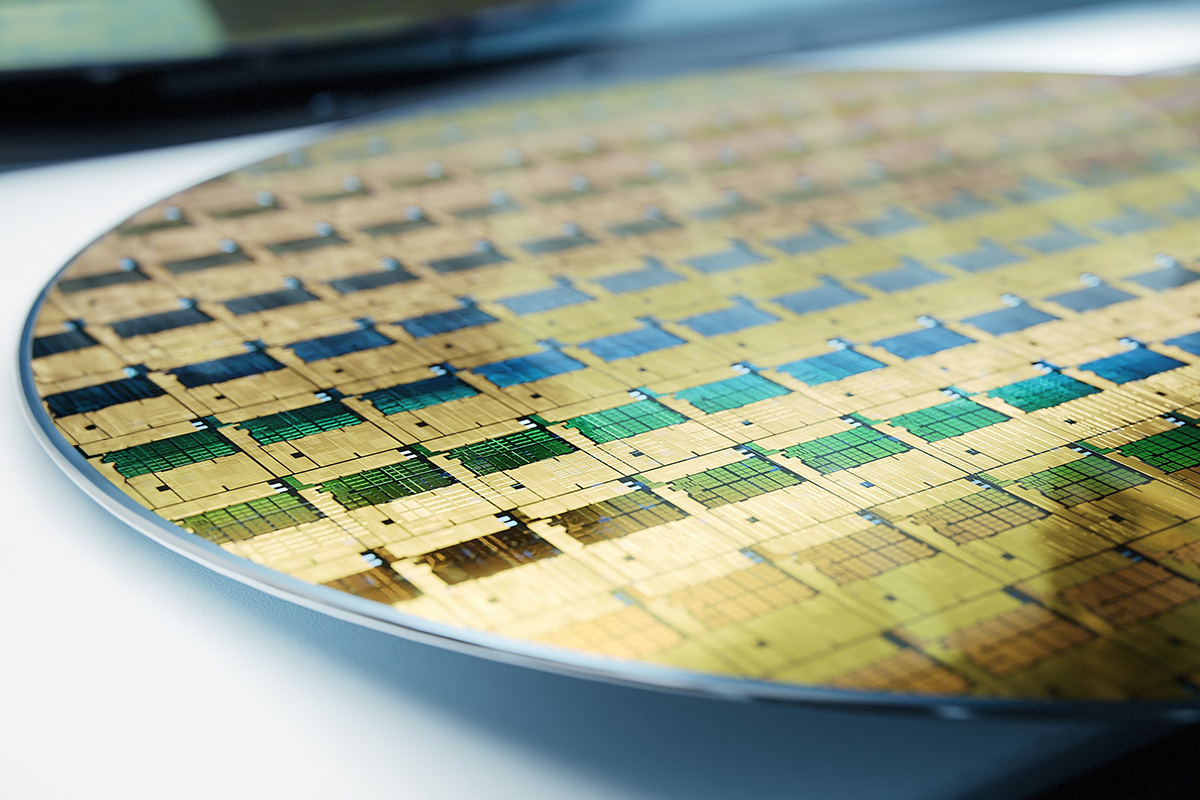

In addition, global demand is increasing, particularly in future-oriented industries such as electric mobility, renewable energies or high-tech components. This intensifies competition for available quantities.

4. Strategic procurement: What companies should do now

Industrial companies are increasingly responding strategically to these developments. The following measures have proven effective:

- Diversification of supplier countries and producers instead of dependence on individual sources

- Early notifications of requirements and longer-term framework agreements

- Building up redundant stock levels for critical powder types

- Partnerships with specialised raw material and powder producers to ensure consistent quality

- Regular monitoring global market trends

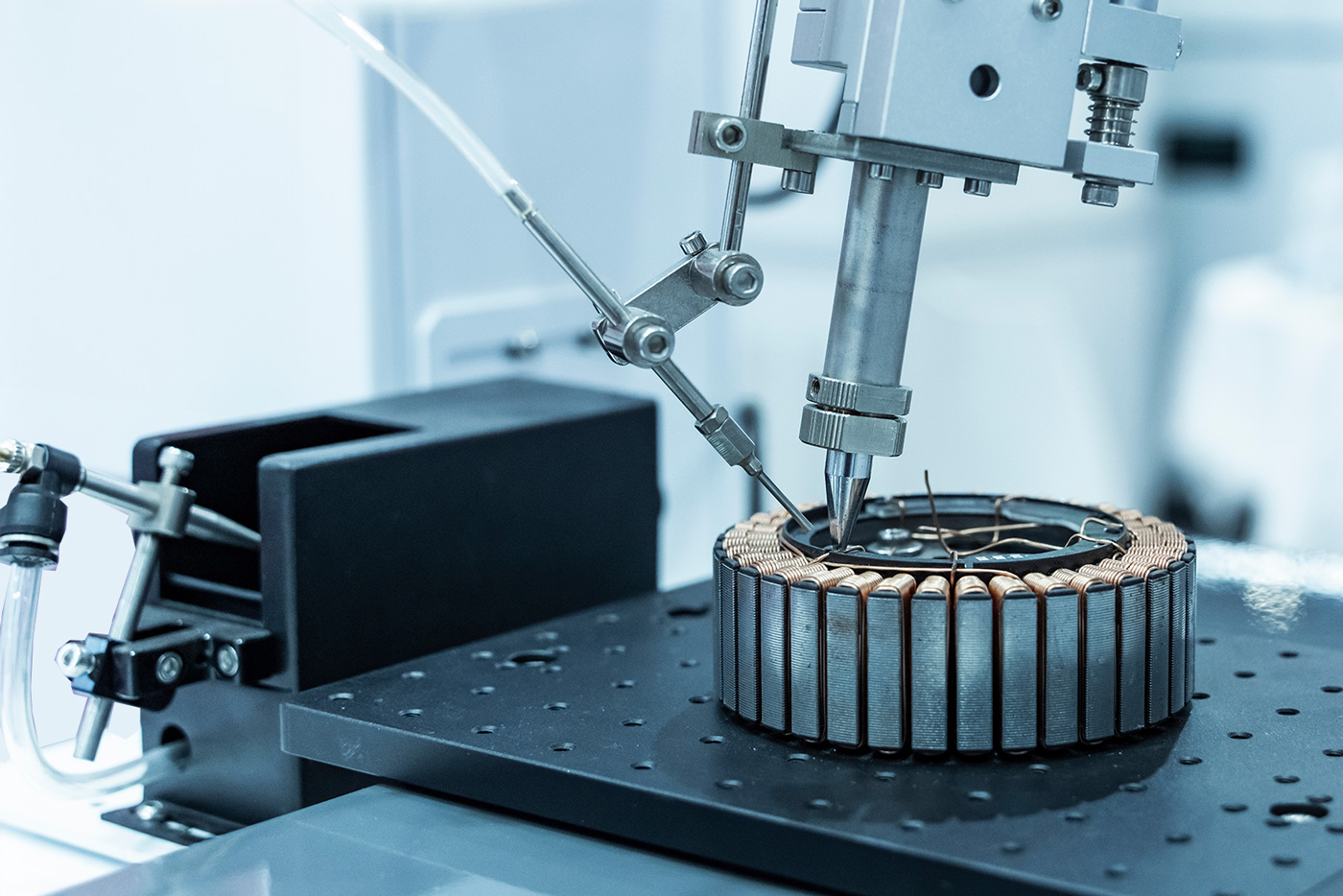

Particularly in the field of highly specialised metal powders (e.g. for additive manufacturing, thermal spraying or special alloys), close technical coordination between the manufacturer and the customer is crucial to ensure security of supply and consistent quality.

Conclusion: Resilience is becoming a competitive factor

Metal powder procurement is currently influenced by numerous global factors. Companies that establish stable and broad supply chains not only benefit from greater planning reliability, but also secure long-term competitive advantages.

Transparent communication, flexible procurement strategies and reliable partnerships thus become key components of a resilient supply chain.