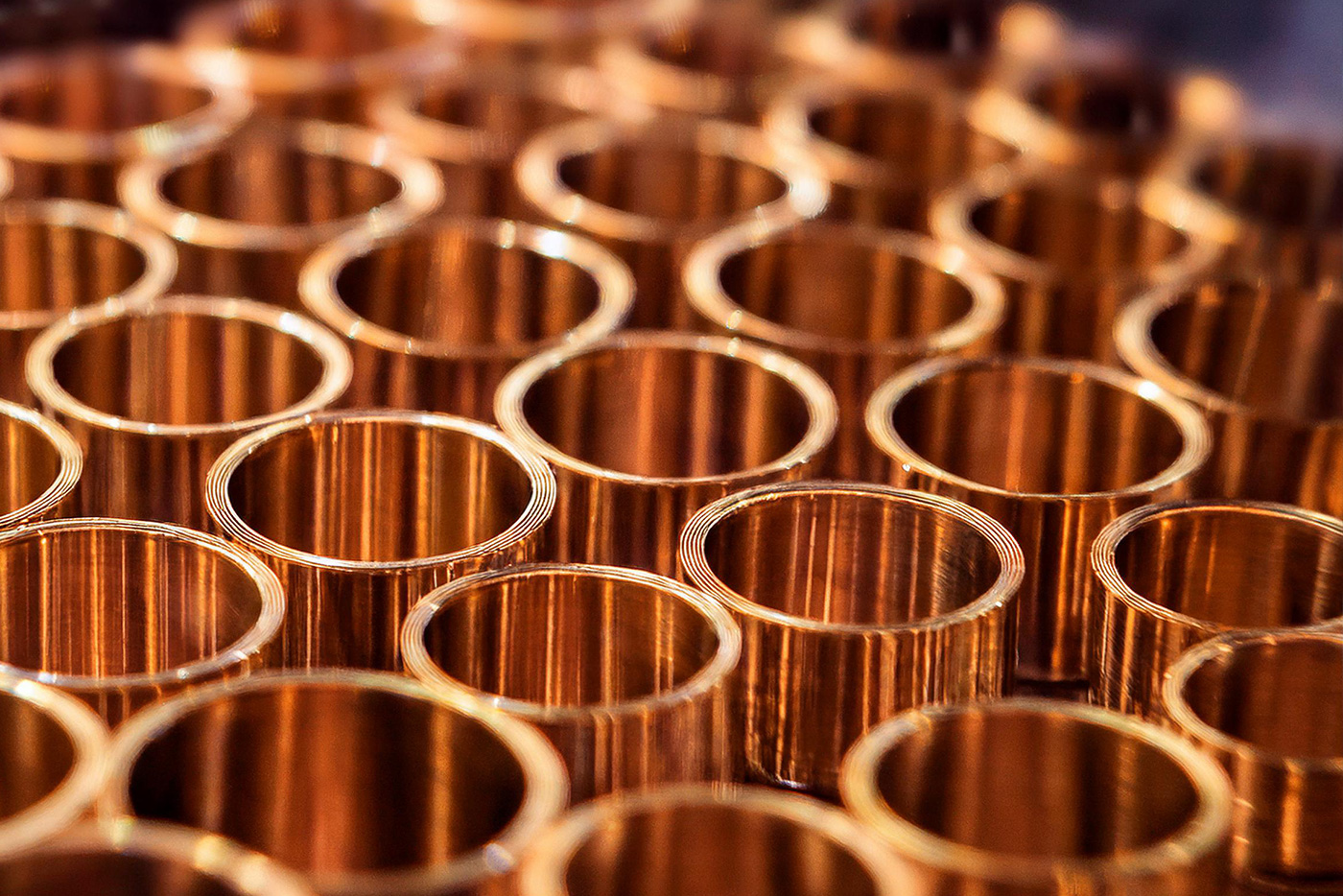

In 2025, ferrites will be among the indispensable materials in the electronics and electrical engineering industry. Especially in powder form, ferrites play a key role as they enable customised and precise magnetic properties that offer a significant competitive advantage in a wide range of applications.

But why exactly are ferrites in powder form more important today than ever before?

Industrial relevance and increasing importance of ferrite powders

As digitalisation and electrification progress, the demand for efficient magnetic materials is increasing enormously. Ferrite powders offer decisive advantages here by combining high magnetic efficiency with low losses.

These properties enable the production of more powerful and more compact electronic components. Ferrite powders therefore make a decisive contribution to further improving the energy efficiency and reliability of modern technologies.

Hard ferrites and soft ferrites - differences and applications

Ferrites are basically divided into two main categories: Hard ferrites and soft ferrites. Each category has specific properties that make them ideal for different applications.

Hard ferrites - permanent magnetisation for long-term stability

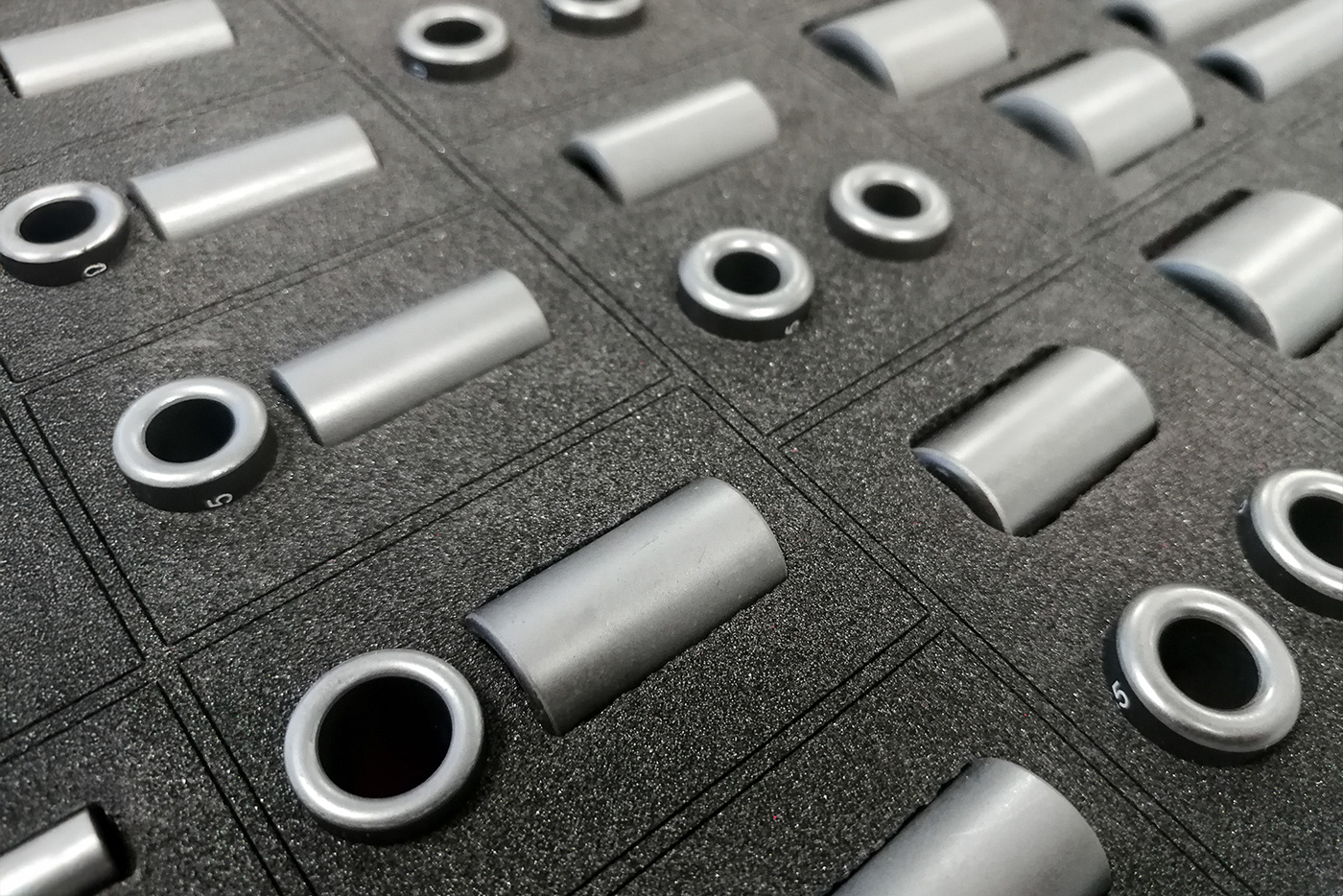

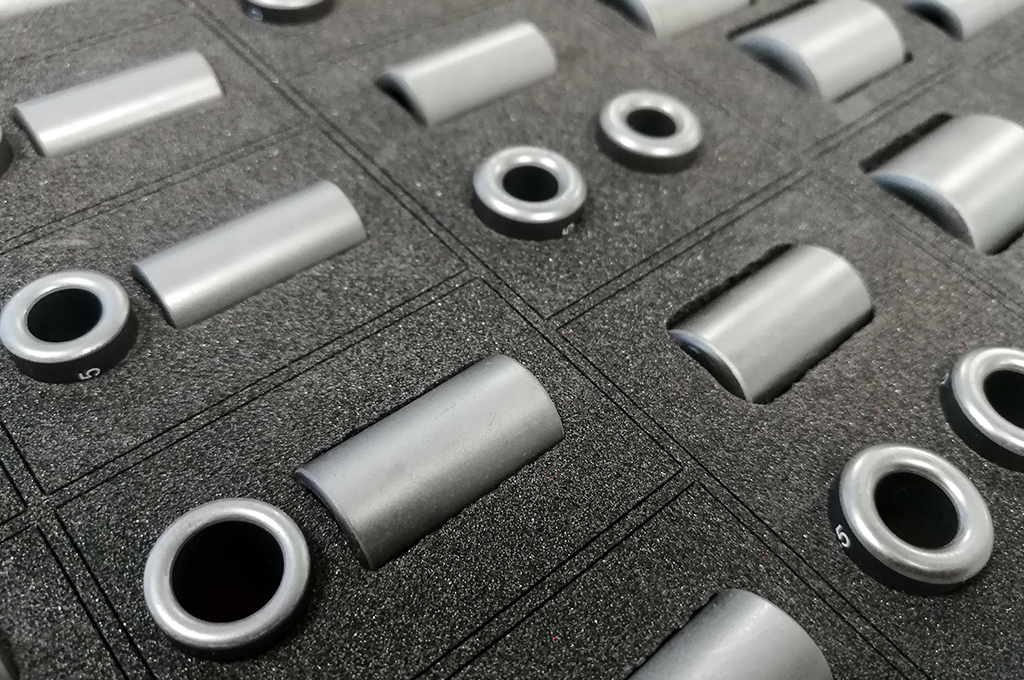

Hard ferrites, such as the Sr ferrite powder from NMD Metalpowders, are characterised by a high coercive field strength. This property ensures that they can retain their magnetic alignment over long periods of time. Typical applications for hard ferrites include

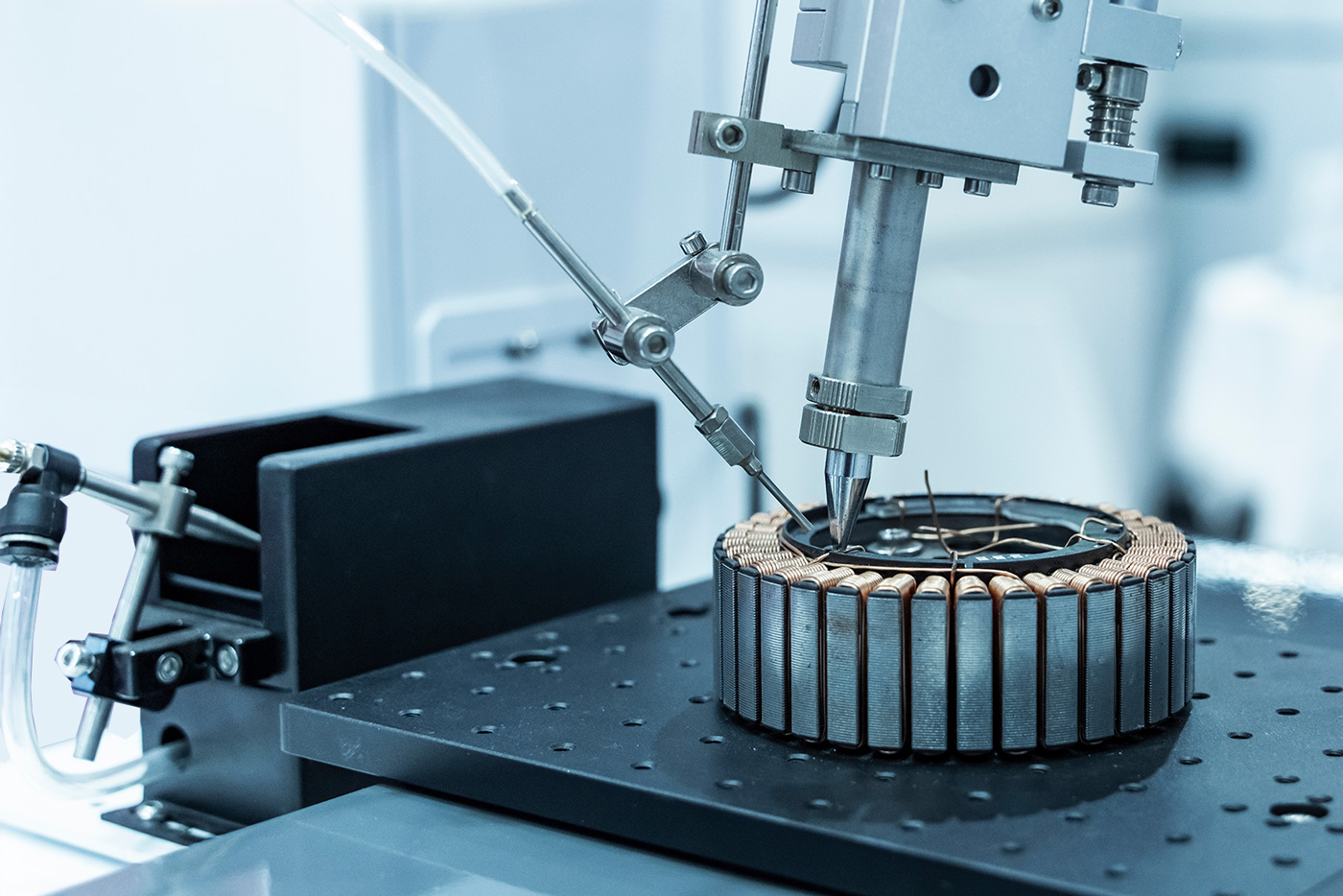

- Electric motors

- Generators

- Loudspeaker

- Magnetic holding devices

The special chemical stability and temperature resistance of the Sr ferrite powder ensures a long service life and high reliability of the components.

Soft ferrites - optimised for high-frequency and electronic applications

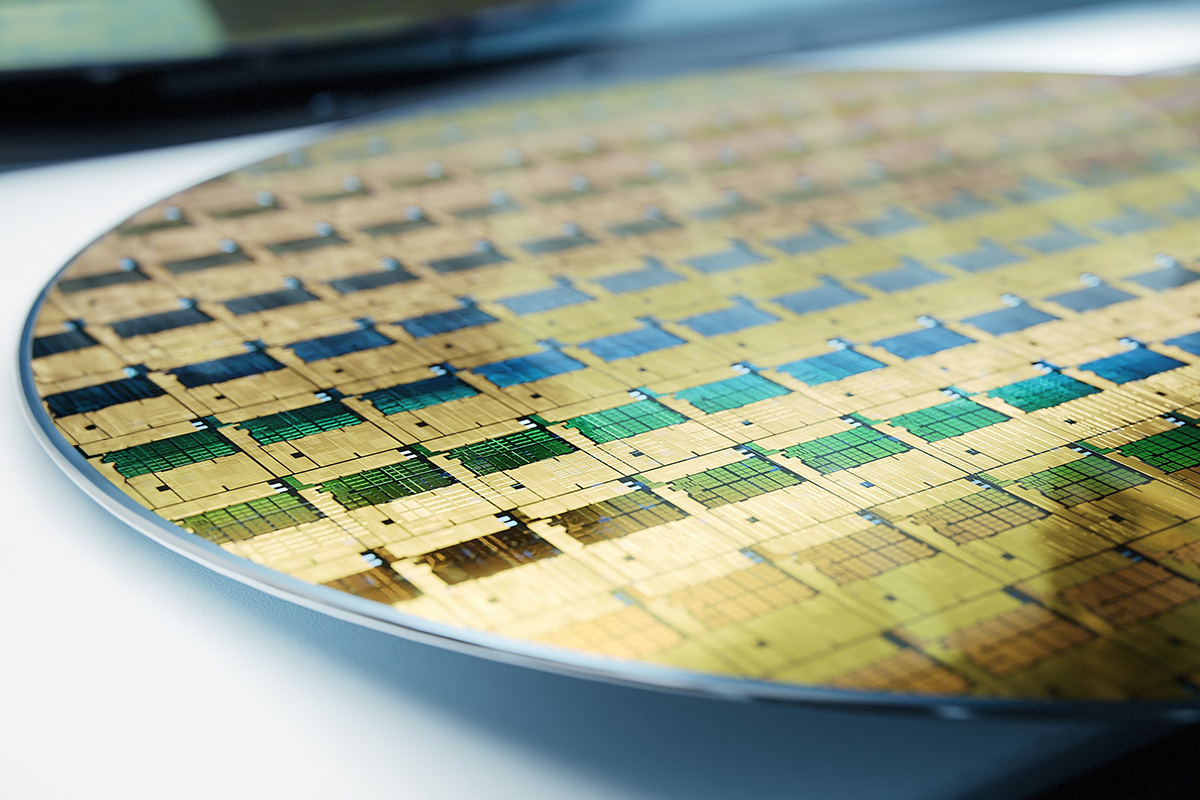

Soft ferrites impress with their low magnetic losses and high permeability, especially in high-frequency applications. NMD offers specialised ferrite powders such as the MnZn ferrite Mf197 and the NiZn ferrite powderwhich have been specifically developed for demanding applications:

- MnZn ferrite Mf197: Specially designed for transformers and high-frequency applications, it offers excellent permeability and low losses, ideal for telecoms equipment and electronic components.

- NiZn ferrite powder: Optimised for applications in power electronics and telecommunications, it guarantees efficient signal transmission and minimised losses.

NMD Metalpowders - Your expert for high-quality ferrite powder

Choosing low-quality ferrite powders can have serious consequences, such as production delays, technical failures and increased operating costs. NMD Metalpowders counters these risks with customised solutions that are precisely tailored to the requirements of modern production processes.

Your benefits with ferrite powders from NMD:

- Highest quality: Careful selection of raw materials and strict quality controls ensure consistently first-class magnetic properties.

- Personalised advice: Thanks to our many years of experience, we offer specific advice to develop exactly the right solutions for your applications.

- Reliable supply: Thanks to stable supply chains, we guarantee reliable and timely delivery of the required ferrite powder.

Mastering challenges - securing competitive advantages

The market for electronic and electrotechnical components is highly competitive. Companies that rely on innovative and high-quality ferrite powders secure decisive competitive advantages here. Ferrite powders from NMD help to make your products more powerful, efficient and reliable.

Conclusion and outlook

In 2025, ferrite powders have become indispensable in electrical engineering and electronics in order to develop innovative products and secure market share. The special properties of hard and soft ferrites in powder form make it possible to manufacture highly precise, efficient and reliable magnetic components. Rely on the expertise of NMD Metalpowders to make your production future-proof and competitive.