Main Menu

Metal powder

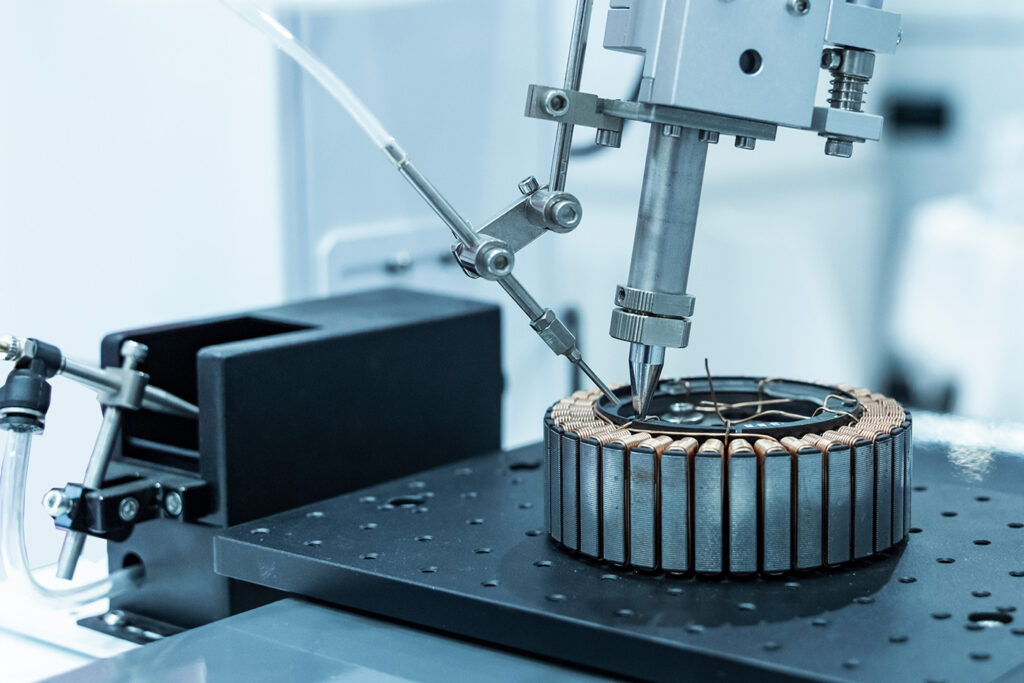

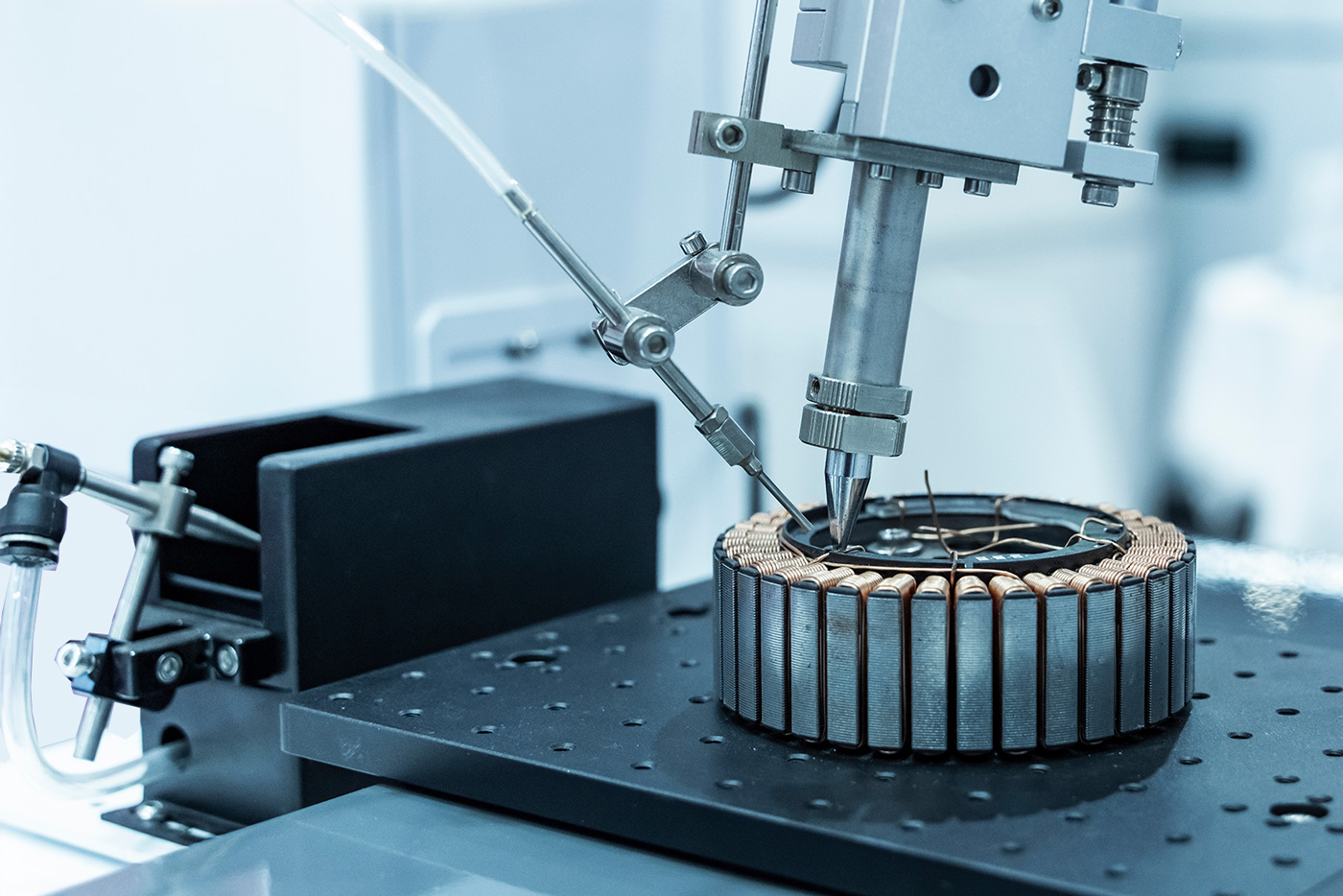

Precise soldering with high-performance soldering powders: With our soldering powders you can achieve Significantly more precise dosing than with soldering wires. A real advantage in the automation of manufacturing processes.

NMD Metal Powders brings over 25 years of expertise to the development and supply of specialised solder powders optimised for precise industrial processes. Our powders are used in numerous industries and applications where maximum reliability and consistent quality are required.

We are your reliable source for industrial soldering powders such as

Download our current overview of all available soldering powders as a PDF:

Our soldering powders are ideal for applications that require maximum precision and reliability, both in the field of soft soldering and hard soldering.

Hard soldering with powder (temperature ~590°C)

Aluminium-silicon alloys such as AlSi7, AlSi10 and AlSi12 are mainly used for brazing, often in combination with stainless steel (CrNi steels).

Our powders are characterised by very low oxygen contents and a consistently narrow particle size distribution - the basis for stable processes in the automotive industry and in machine and tool construction.

Soft soldering with powder (temperature ~ 250°C)

For soft soldering, lead-free SnAgCu alloys such as SAC305 are the standard in electronics production. With their narrow grain distribution and very low oxygen content, they are ideal for SMT (surface mounting technology) processes, where precision and process reliability are crucial.

Our range includes a variety of powder materials for different soldering processes:

Typically used for soft and hard soldering applications with materials such as Sn96.5Ag3.5 or SAC305 in paste form for precise application.

Ideal for fine, detailed soldering work. Frequently used materials are fine SnAgCu alloys such as SAC305.

For more robust, industrial applications, often with high-melting-point solder powders such as AlSi alloys for brazing processes.

Used for mass production, typically with resistant materials such as AlSi10 and AlSi12 as well as SnAgCu alloys for consistent and reliable results.

Used for special applications where no flux is used and the connection must be made quickly. Frequently used materials are pure tin alloys such as SnCu.

Industrial soldering offers great potential in the production of components that place high demands on precision and material properties. Our specialised soldering powders make it possible to realise even complex and demanding production tasks efficiently and reliably. By selecting specific soldering powders for hard and soft soldering processes, you can significantly improve the quality and performance of your products.

Automotive industry

In the automotive industry, solder powders are used for control units, sensors, e-mobility components and cooling modules. The narrow grain distribution ensures vibration-resistant, durable connections.

Aerospace

In the aerospace industry, our powders enable reproducible reflow profiles and reliable solder joints in highly integrated assemblies.

Machine & tool construction

Mechanical engineering and toolmaking benefit from brazing with AlSi systems - for high-strength and dimensionally stable joints.

Electrical engineering

Low-resistance solder joints are indispensable in electrical engineering. Our powders ensure clean print images and precise wetting.

Power generation

In power generation, soldering and coating powders ensure durable, resilient components in renewable energy systems.

Semiconductor Technology & Electronics

In semiconductor technology & electronics, our powders are used for SMT, BGA and fine-pitch designs where maximum precision is required.

Choosing the wrong soldering powder can lead to production downtime, loss of quality and high costs. With NMD Metalpowders avoid these risks. We offer:

With over 25 years of experience, we not only supply you with powder, but also customised solutions that increase your production efficiency and ensure reliable results.

Nadine Rajner

Your contact person

because you have the right powder.

for your products because you can rely on our global supply chains.

in your work, because you have us at your side as your partner.

No problem! If your specific metal powder is not listed here, we are guaranteed to find the right solution for your requirements.

Contact us for individual advice or our customer service on weekdays from 09:00 to 16:00.