Anyone who deals with large or small machines will sooner or later come across the term "tribology". In this article, you will find out exactly what science is behind it and how tribological approaches influence everyday life in industry and mechanical engineering.

What does "tribological" mean? - A definition

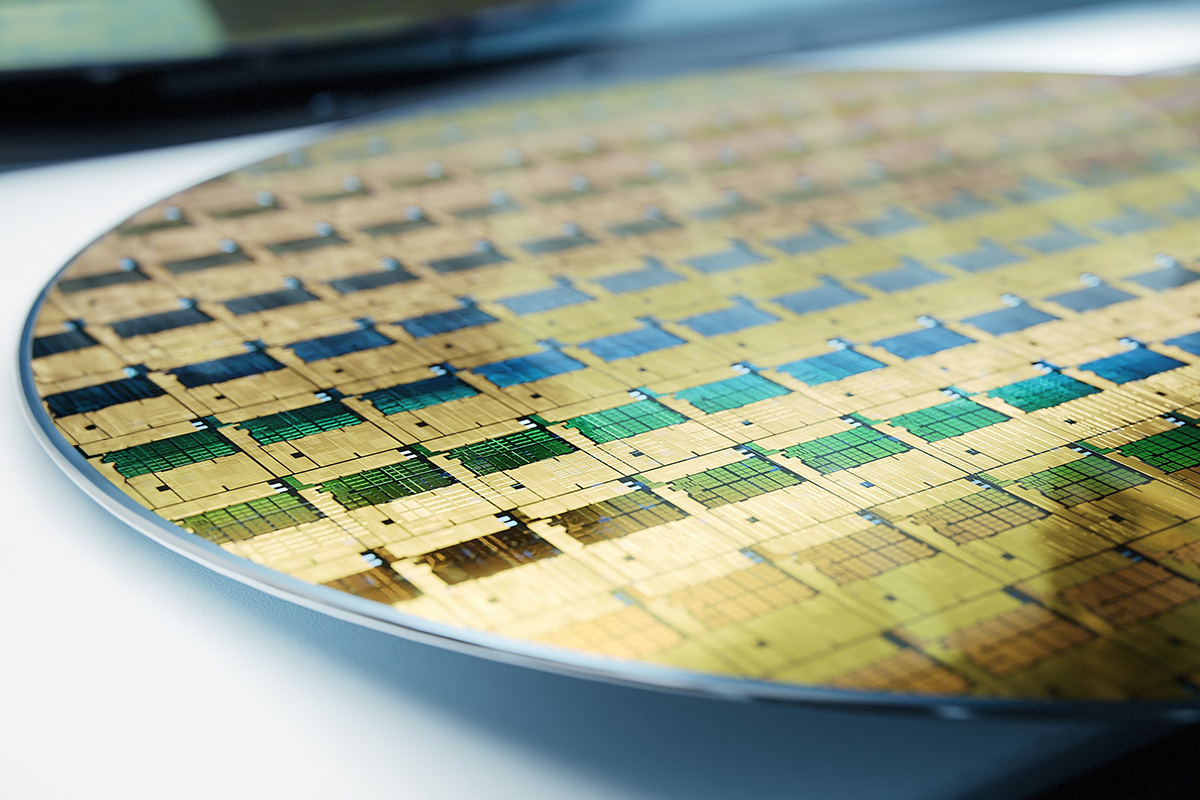

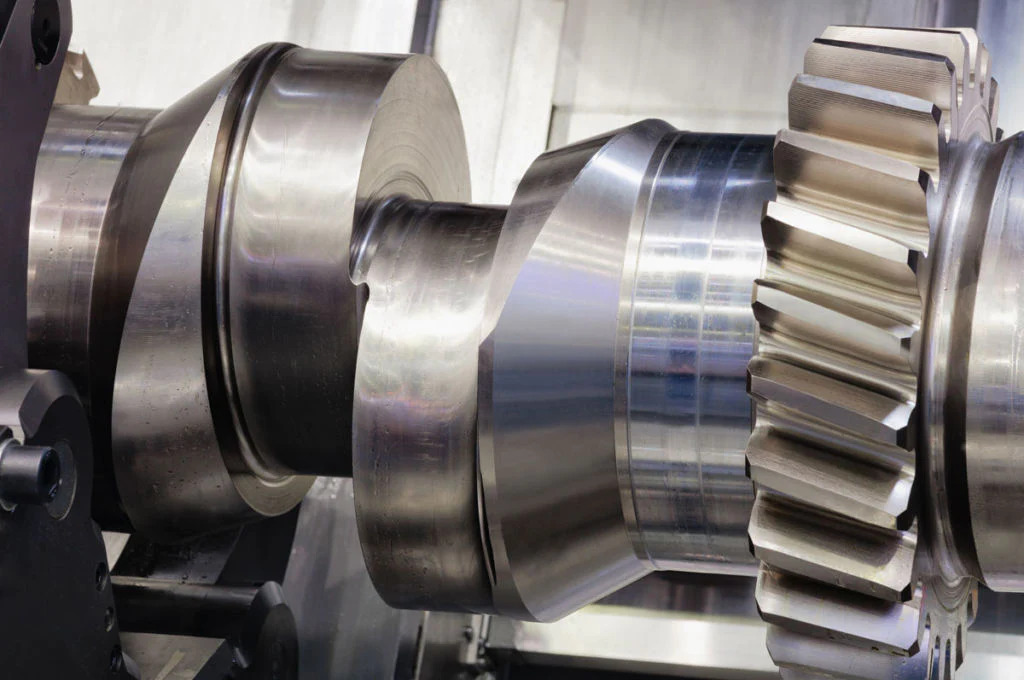

Tribology is about the Friction theory - The scientific study of friction and associated phenomena such as wear or lubrication of bearings, guides, gears, motors and other machine elements. According to this definition, tribology is therefore everything that is considered within the scope of this discipline. Tribology is an interdisciplinary field of study that includes the following specialisms Physics, chemistry, mechanical engineering and materials science investigated. As the external friction between two bodies can never be generated by one object alone, this is also referred to as "tribological systems".

Examples of tribological friction

In addition to more theoretical tests and investigations, friction in the sense of tribology also plays a major role in "real life" - often unnoticed by the user of the relevant parts. Whether large machines in industry and factories or components for everyday use: tribological issues can be found in many practical areas of application.

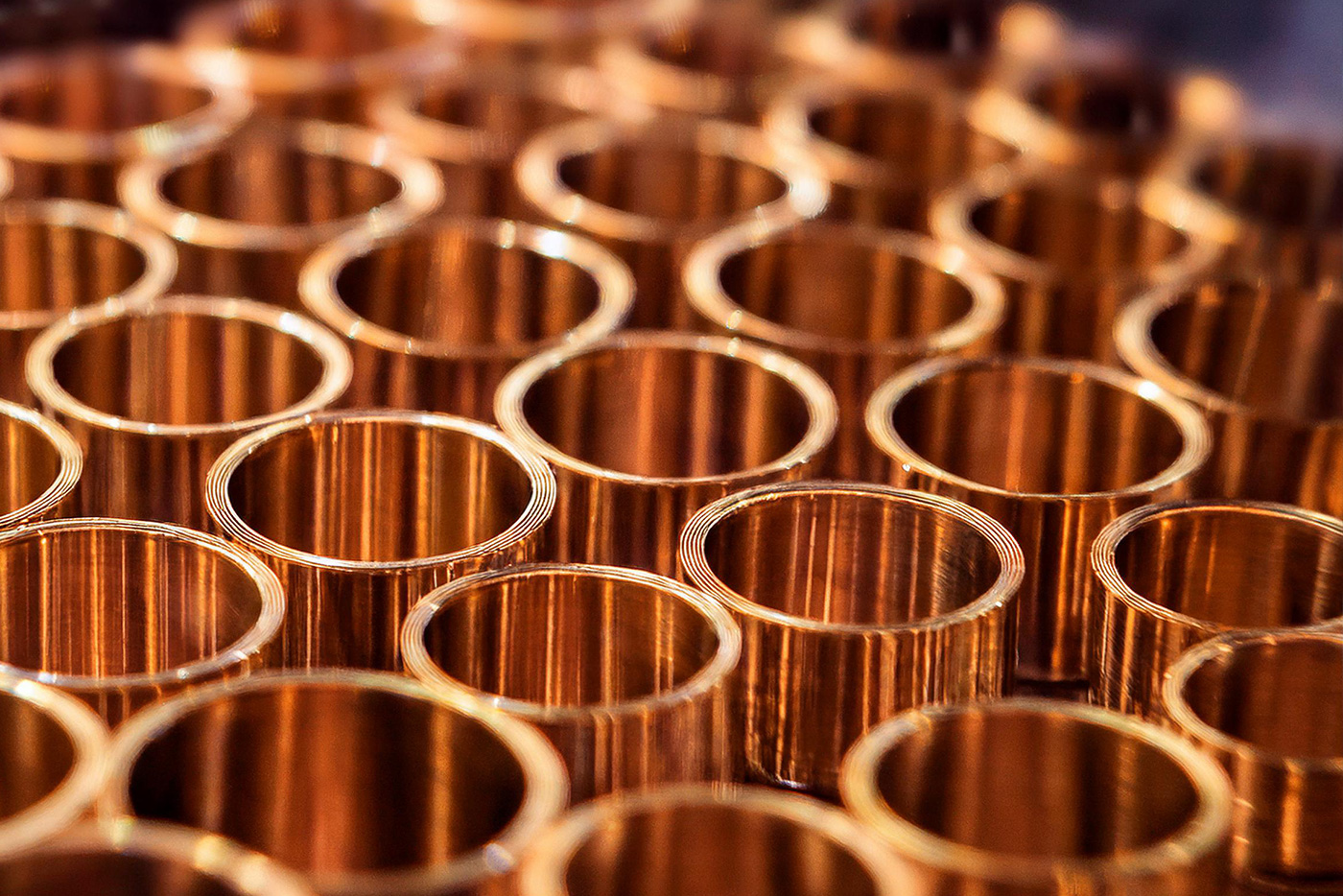

Example 1: Friction between components

Brake linings and clutch linings in vehicles such as cars are permanently exposed to mechanical friction - because this is the only way they can fulfil their tasks. Here, tribology helps to find a compromise between maximum braking effect and minimum wear. Special materials such as metal sulphides ensure that high temperatures under load are avoided and signs of wear are kept to a minimum. Tribological findings can also be used to avoid unwanted vibrations and noise that can be caused by friction.

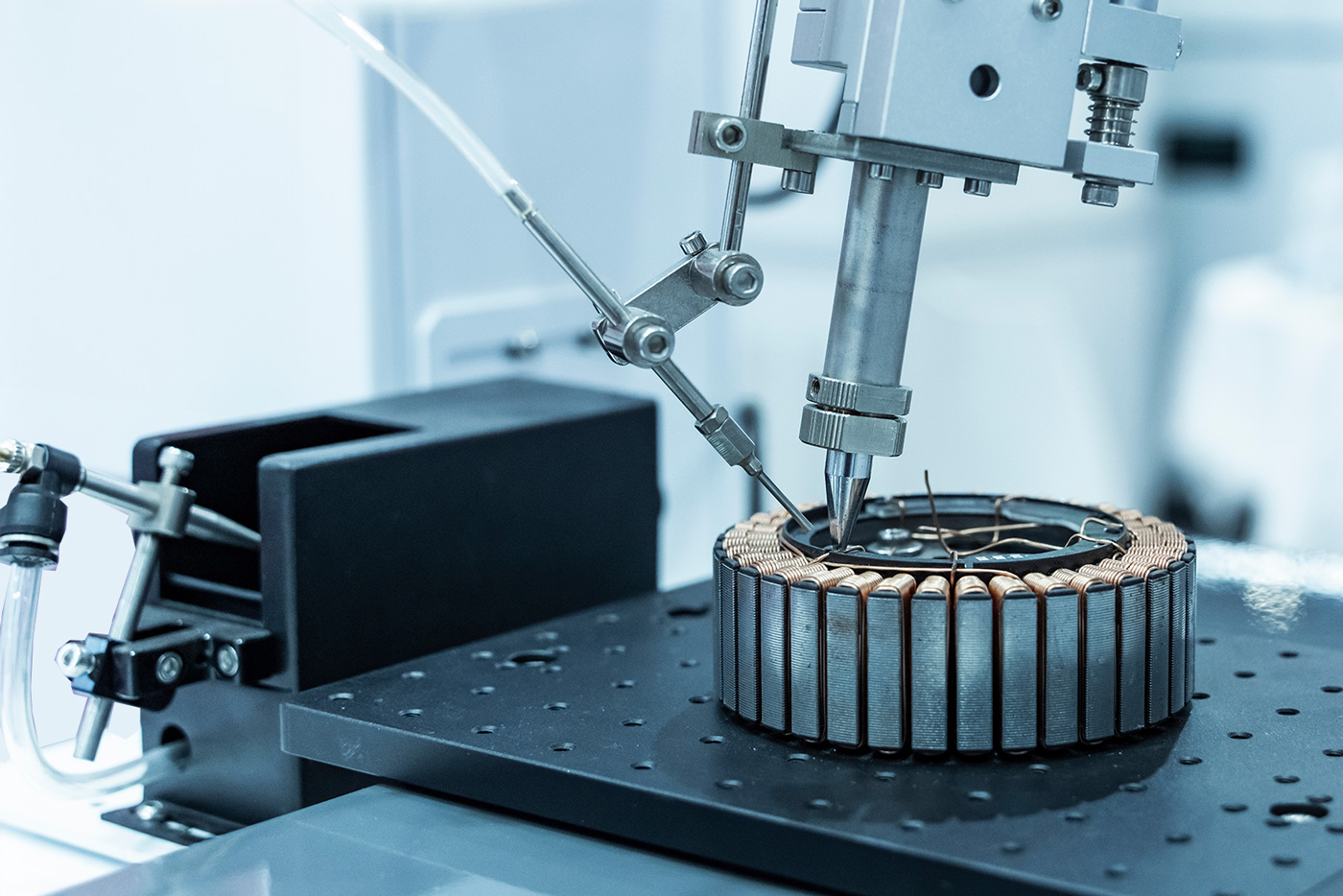

Example 2: Friction between tool and chip

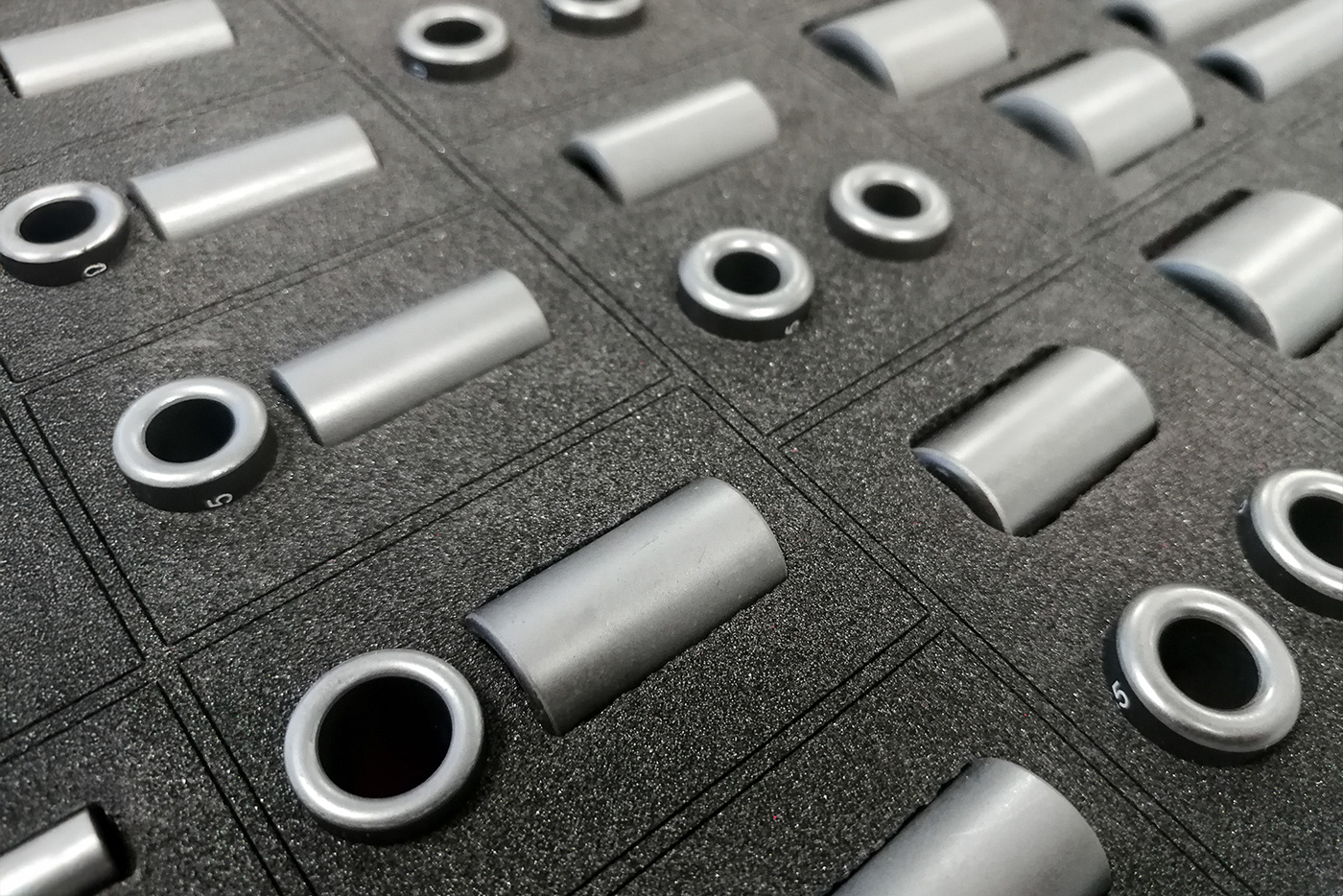

Friction in the tribological sense is also indispensable when it comes to machining workpieces. Tool wear should not be underestimated, especially when particularly hard materials have to be machined. This is primarily a question of machining production processesthat take place within a tribological system, for example:

- Turning

- Drilling

- Milling

- Planing

- Saws

- Files

- Loops

It is often not only the desired parts of the workpiece that are removed. The tools also constantly lose substance due to the resulting friction caused by the abrasive particles. The degree of abrasion depends on the hardness of the workpiece material.

Example 3: Biotribology

Another focus is on the so-called Biotribology. It is particularly concerned with friction phenomena in a biological, natural system - for example in the human body. Among other things, biotribology is looking for ways to make artificial joints more comfortable. For hip joints, for example, titanium is often used, which is considered to be particularly compatible with the human body. The friction that occurs between the hip socket and the femoral head must be minimised as much as possible in order to ensure a high level of comfort. This is where biotribology comes into play, investigating suitable lubricants, coatings and the like in order to find the best solution.

Tribology and sustainability

Scientists and engineers are discovering more and more potential in the field of friction in classic mechanical engineering and in industry in general. This is because the right conclusions, such as the use of suitable lubricants, can not only increase the quality and service life of the various components. Optimising friction and wear also benefits the environment. A 2017 study found that tribology has a significant impact on global energy consumption. According to this, just under 23 % of global energy consumption can be attributed to tribological contacts. With the right tribological technologies, energy loss due to friction and wear could be minimised. reduced by up to 40 % in the long term especially in the areas of transport and energy generation.

By immersing yourself in the subject of tribology, you can not only save money and ensure more satisfied customers, but also have a real impact on our future.

Tribology: An often underestimated speciality

Ultimately, all mechanical friction is tribological by definition. However, analysing tribology offers many opportunities. Those who are familiar with the phenomena surrounding friction can make better material decisions or purchasing decisions, utilise previously unused potential in product development and even make their contribution to sustainable coexistence.