If you want to buy metal powder, you are faced with a huge selection of different products. Basically, it is probably clear what type of metal powder is required or what the starting material should be. However, it can quickly become difficult when it comes to the details. We have three tips for you to make buying the best metal powder easier.

Buying metal powder: Do you know what's important?

Choosing the right metal powder for industrial purposes is a complex matter. The various powders differ in many respects, such as

- Type of raw material

- Manufacturing process

- Powder particle structure

- Possible applications

- Individual properties

- Storage requirements

- Costs and available quantity

It is therefore essential to take a close look at the different product properties in order to be able to buy the right metal powder in the end. However, you don't have to dive straight into the depths of the chemical details to make a pre-selection. If you are unsure about what to look out for in the first step, the following tips will help you.

Tip 1: Take a close look at the application

The first question is: What do you need the metal powder for? Metal powders are used in numerous industries and for a wide variety of applications. And it goes without saying that you need to buy a different metal powder for an application in the cosmetics sector than for the manufacture of car parts. Some of the typical industries in which metal powders are used include

- Paint and colour industry

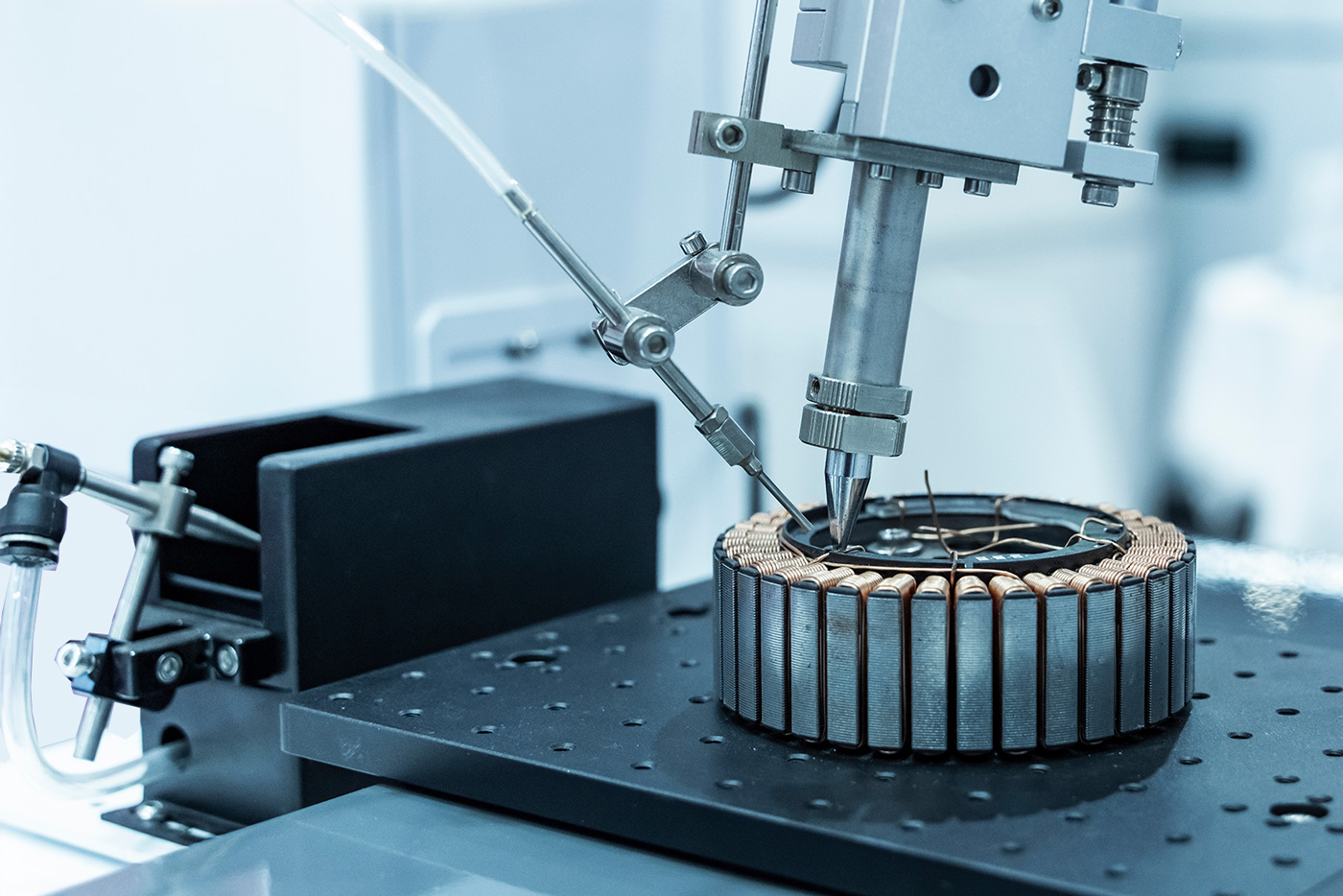

- Electrical industry

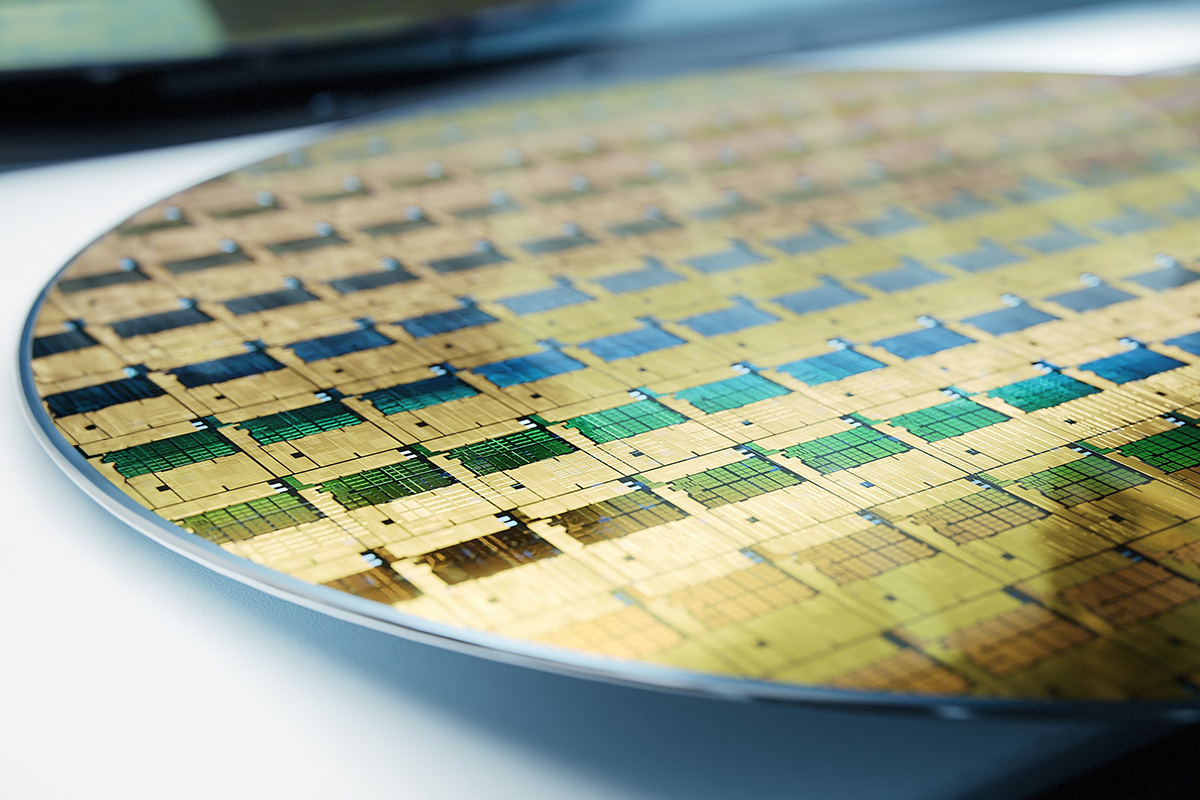

- Automotive industry

- Cosmetics industry

- Printing industry

- Nuclear industry

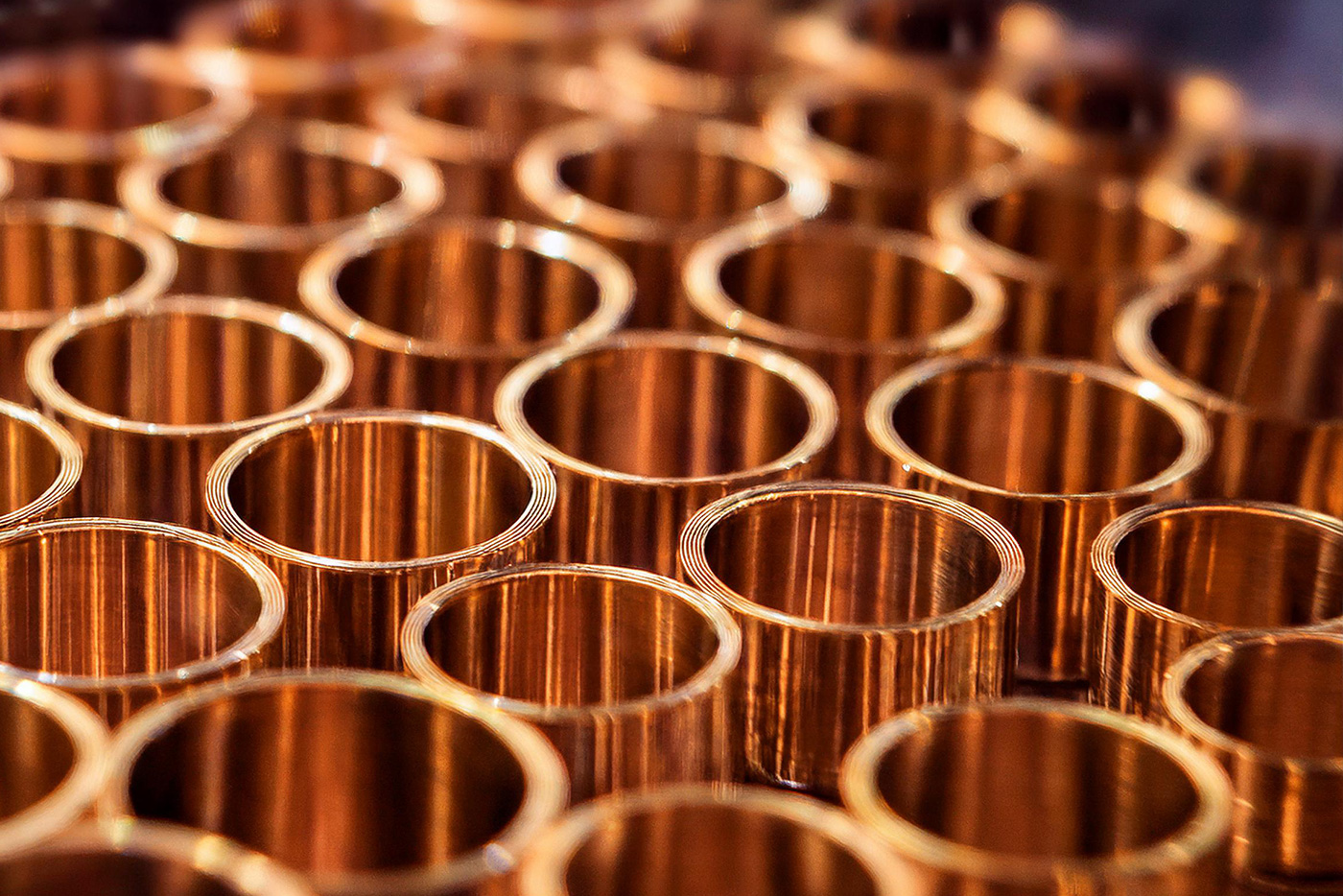

Even if you have had good experiences with a particular metal powder in the past, this does not automatically mean that it is the best choice for another application. The most common metal powders include powders made from magnesium, aluminium, aluminium-silicon, bronze, copper, brass, zinc or iron. Another category includes speciality powders such as solder powder, nickel, titanium, silver, vanadium, germanium and hafnium powder.

Tip 2: Consider challenges during processing

In the next step, turn your attention to the processing. The following applies here: not every powder is ideal for every type of processing.

Common types of processing

- Sintering

- Metal injection moulding MIM

- Additive manufacturing

- Selective laser melting SLM

- Surface spraying process (HVOF, plasma, cold gas, ...)

- Chemical reactants (blue dye for jeans)

This brief overview already shows that there are various ways of moulding the metal powder into the desired shape or integrating it into the respective end product. It is therefore essential that you also consider the type of processing, as it goes without saying: A metal powder that is used in 3D printing must fulfil different requirements than a powder for classic sintering applications.

Also crucial: Consider whether and which additives should be used when you buy metal powder. Metal powders are often mixed, whether with other metals or useful additives that are intended to improve the product properties. It is crucial here that the respective base materials are compatible with each other and that no dangers arise from mixing.

Tip 3: Take advantage of counselling

Regardless of whether you are an old hand in the business or gaining your first experience in powder metallurgy: If you want to buy metal powder, good advice is never a bad idea. Even those who are familiar with the typical applications and characteristics of individual metal powders can benefit from an independent expert opinion. Especially in day-to-day business, it is not always easy to keep up to date with developments in the industry. However, new findings or innovative approaches in the production and processing of metal powders can give you and your company an additional boost. Especially if you are looking for the right metal powder for a completely new area of application.

If you have taken tips 1 and 2 to heart, you are well prepared for a discussion with a specialist. You know what you want to achieve in the end and which process you want to use to get there - and with the right advice, you will also find the most suitable metal powder. Perhaps the discussion will also result in a new, improved approach that will bring long-term benefits. Buying on "good luck" and according to the motto "We've always done it this way" may work for simple standard applications. However, if production is to be optimised, it is worth looking left and right the next time you buy metal powder. If you need support with your purchase, please feel free to arrange a meeting with us!

Many factors play a role when you buy metal powder

"One magnesium powder, please": unfortunately, buying metal powder is rarely that simple. As with all industrial applications, there are numerous aspects to consider in order to turn the starting material into an end product of the desired quality. However, don't be put off by the large selection and proceed step by step. It's like buying a car: there, too, you don't start with the optional extras, but work your way from the broad aspects to the details. This approach also works here. This way, you can buy exactly the metal powder that fulfils all requirements with ease and certainty.