Solder powder or solder metal powder is an alternative to the classic solder in wire form. While hobbyists and DIY enthusiasts have already added solder powder and the pastes made from it to their repertoire, some industrial users are still sceptical about the whole thing. We therefore answer the most important questions about solder powder to help you achieve the best results.

Solder powder: A real alternative to solder wire?

In recent years, solder powder has been increasingly used in industrial applications instead of the typical solder. However, especially if you want to switch existing processes in your company to solder powder or you want to integrate a completely new soldering process, there are some questions about the ideal processing method. Even if the basic principle of soldering remains the same, there are a few things you should bear in mind when switching to soldering powder.

What types of soldering powder are there?

Solder powders are almost exclusively alloy powders. Regardless of the type of soldering, both lead-free and lead-containing solders are used. Typical distinguishing features of solder powders include

Material composition:

Common soldering powders are, for example:

- Sn96.5Ag2.5Cu0.5

- Pb70Sn30

- Pb63Sn37

- Pb60Sn40

- SAC305

- SAC405

Grain size:

Two typical grain sizes < 63µm and < 150µm are common for aluminium-silicon solders. For soft solders such as SAC305, a distinction is made between T3, T4 and T5. T3 ranges from 45 - 25µm, T4 from 38 - 20µm and T5 from 15-25µm. Lead/tin solders are usually < 45, < 63 and < 75µm.

Grain distribution:

A consistently uniform grain distribution helps you to establish a stable soldering process.

oxygen content:

Keeping the oxygen content of the soldering powder as low as possible also contributes to the success of the soldering process. The amount of flux used can be reduced as a result.

The solder powders are not normally used in their pure form, but as a solder paste. This paste is created by adding a suitable flux, which is also required in conventional soldering, to join the parts together as desired.

Where can soldering powder be used?

As with soldering with solder in wire form, solder powder can also be used for both hard soldering and soft soldering. This means that they can be used across numerous industries and areas of application.

Brazing

For hotter brazing with temperatures around 590° C, solder powder based on aluminium is often used. Other brazing powders consist of silver, brass or phosphorus, for example. Brazing with powder is suitable for cooking pots with a stainless steel base or for heat exchangers in the automotive industry, for example.

Soft soldering

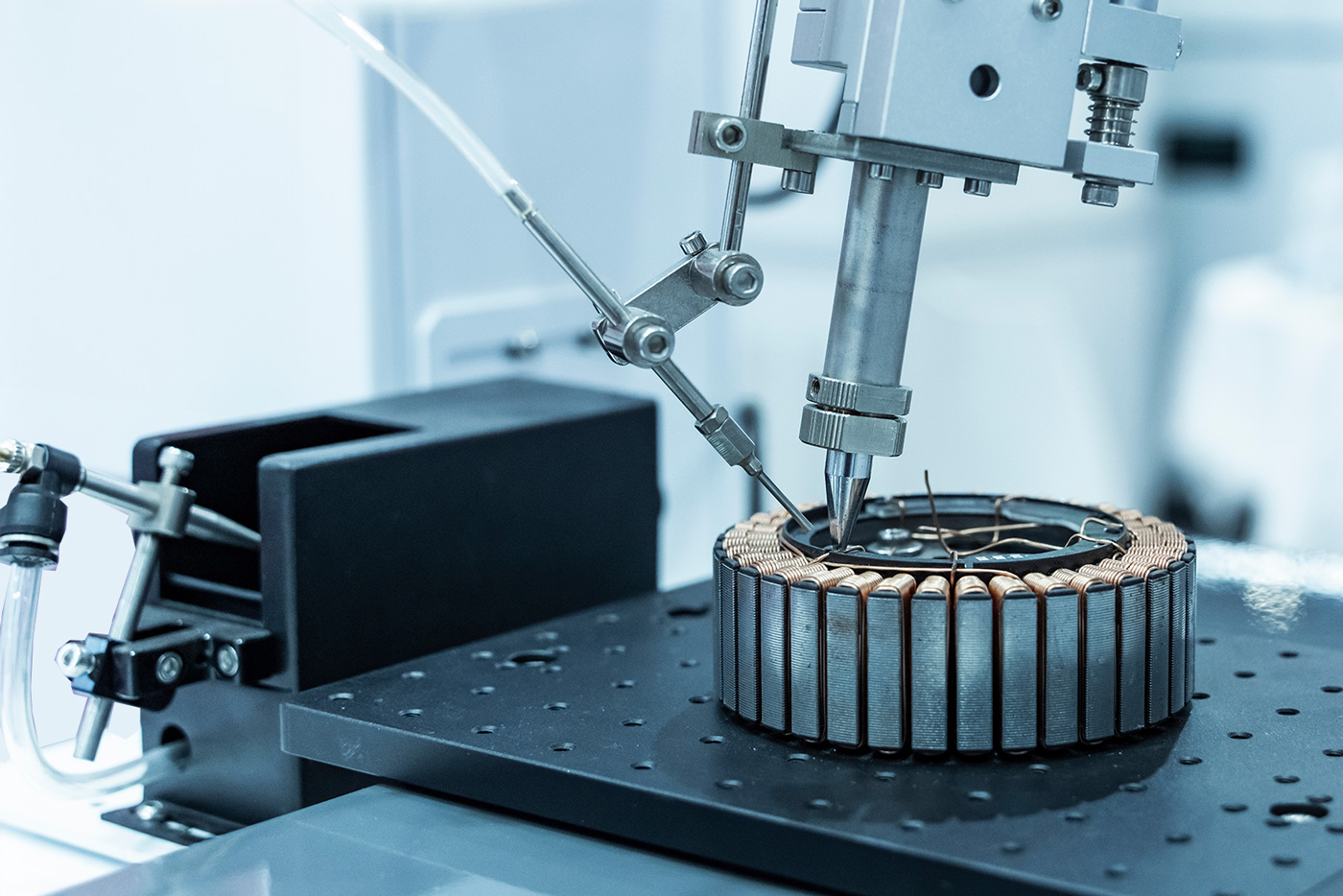

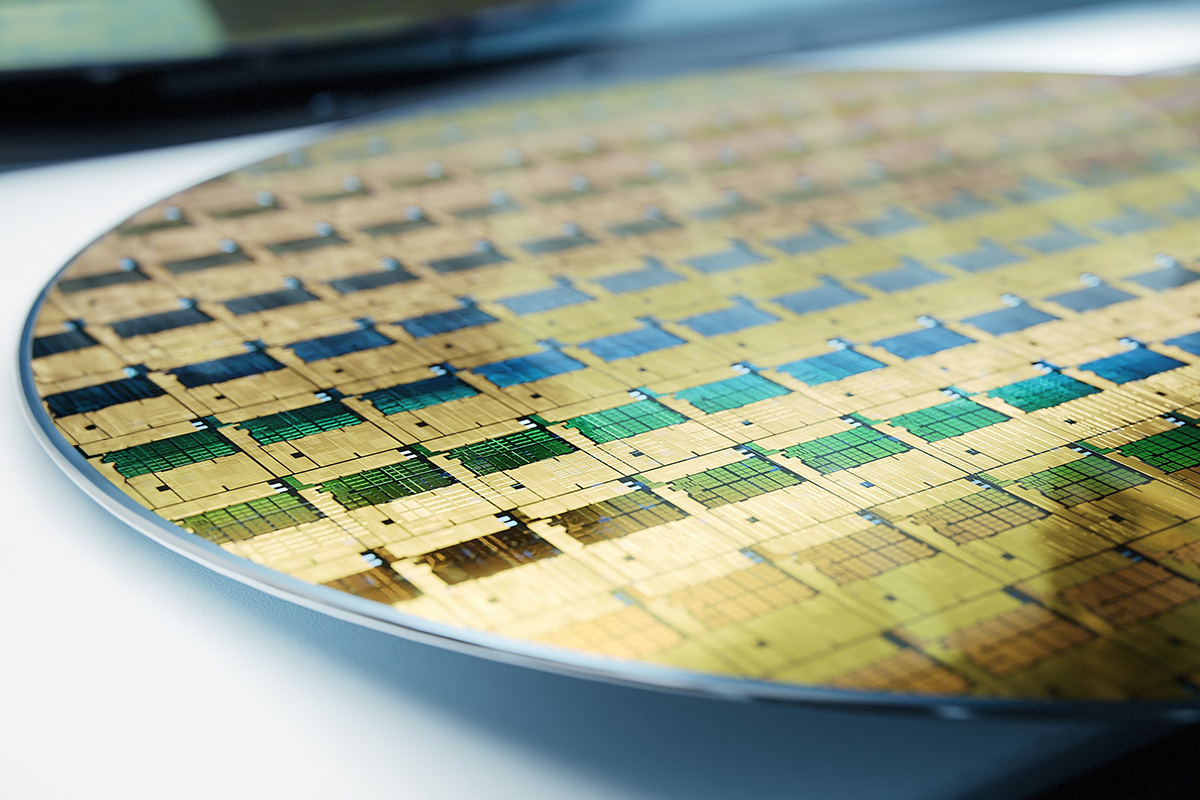

Solder powders based on tin-silver-copper, which melt at temperatures of around 250° C, are popular for soft soldering. These solders are primarily used in the electrical industry for the production of sensitive components in surface mount technology (SMT).

How is the soldering powder used?

Depending on the type and composition of the soldering powder, you must take various aspects into account during processing. Only then are safe working and perfect results guaranteed. The decisive factors include

- Ideal soldering atmosphereWhat does the current soldering atmosphere look like or do you have to adapt the atmosphere to the preferred soldering powder? Under certain circumstances, soldering is possible in a vacuum as well as using inert gases, hydrogen or dissociated ammonia.

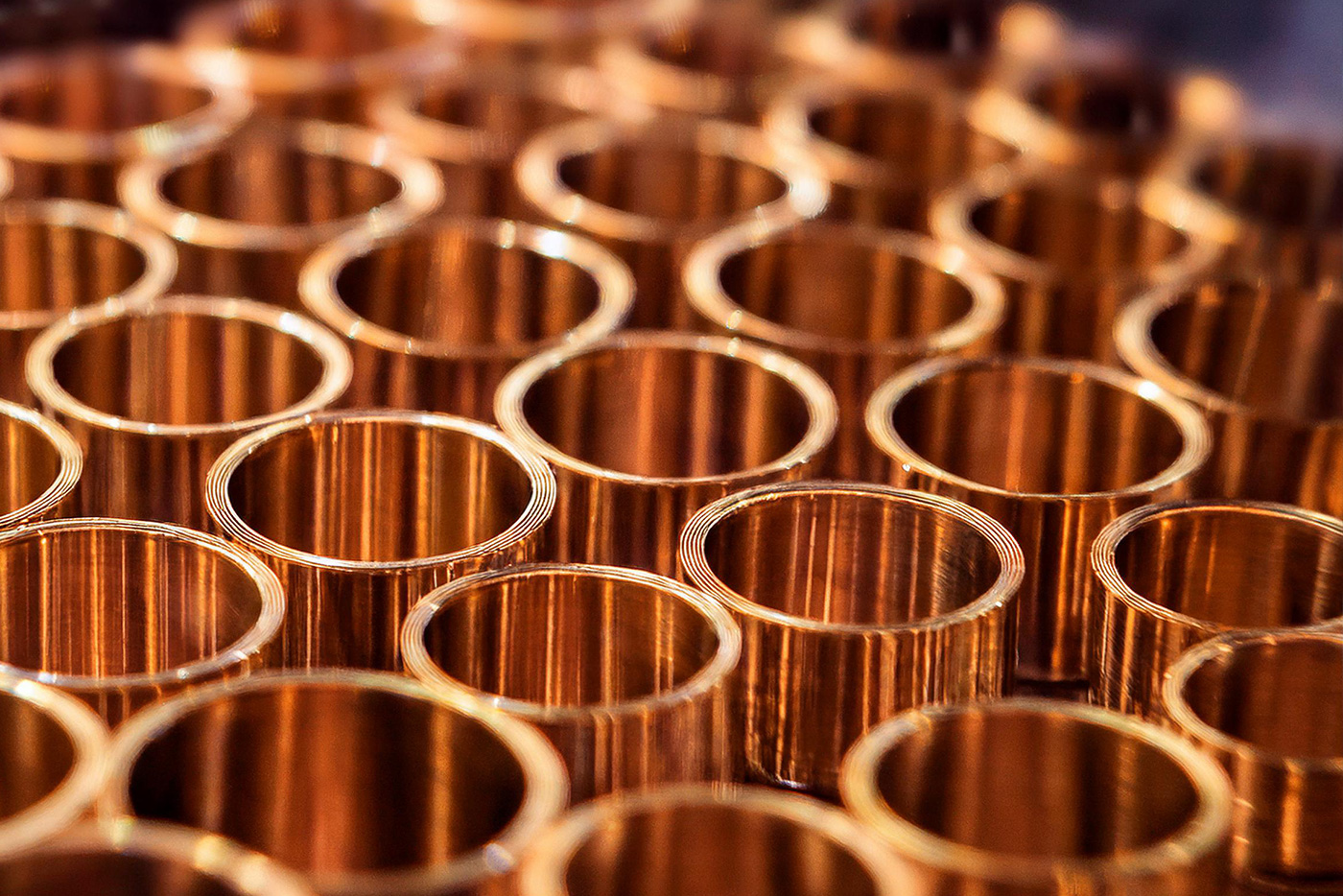

- Type of fluxWhich flux is the right one for the soldering powder and the desired soldering process? In addition to multi-purpose fluxes, there are also special fluxes for tin-aluminium alloys, stainless and high-alloy steel or nickel and copper brazing powder. Some fluxes are only suitable for soft or hard soldering. With some fluxes, the solder joint must be cleaned after soldering, otherwise corrosion may occur and the workpiece may be damaged in the long term.

- Soldering areaIs the desired alloy designed for the required temperatures? If the alloy has to be heated too much, the workpieces can be damaged. The actual advantage of soldering over welding, for example, would then be lost.

What are the advantages of solder powder?

If you take all the important properties of soldering powder into account, there is hardly anything to be said against using it in your company. This is because the use of solder powder has a decisive advantage over classic solder wire. The powder or solder paste makes it easier to automate the soldering process. Soldering material and flux are simply applied in one step in the form of mixed solder pastes instead of one after the other.

The amount of flux is always the same, as long as no mistakes are made when mixing the solder paste. This guarantees consistent solder joint quality without the need for readjustment. The solder paste is easy to dose, making it easier to automate the process. You can therefore use soldering powder to ensure more efficient production in your company. The one-off changeover and possible retooling of the machines quickly pay for themselves.

All-rounder soldering powder

Soldering powder offers you numerous possibilities when it comes to joining workpieces together. It is in no way inferior to its big brother, the solder wire. Whether you use ready-made soldering pastes or put together a customised mixture of the ideal soldering powder and a flux of your choice depends on the individual knowledge, requirements and possibilities in your company. The customised composition of a suitable soldering powder that is precisely tailored to your requirements can raise quality to a new level and open up new possibilities.