Welding applications

Optimised metal powder solutions for Reliable and precise welding - Quality and efficiency for demanding production processes.

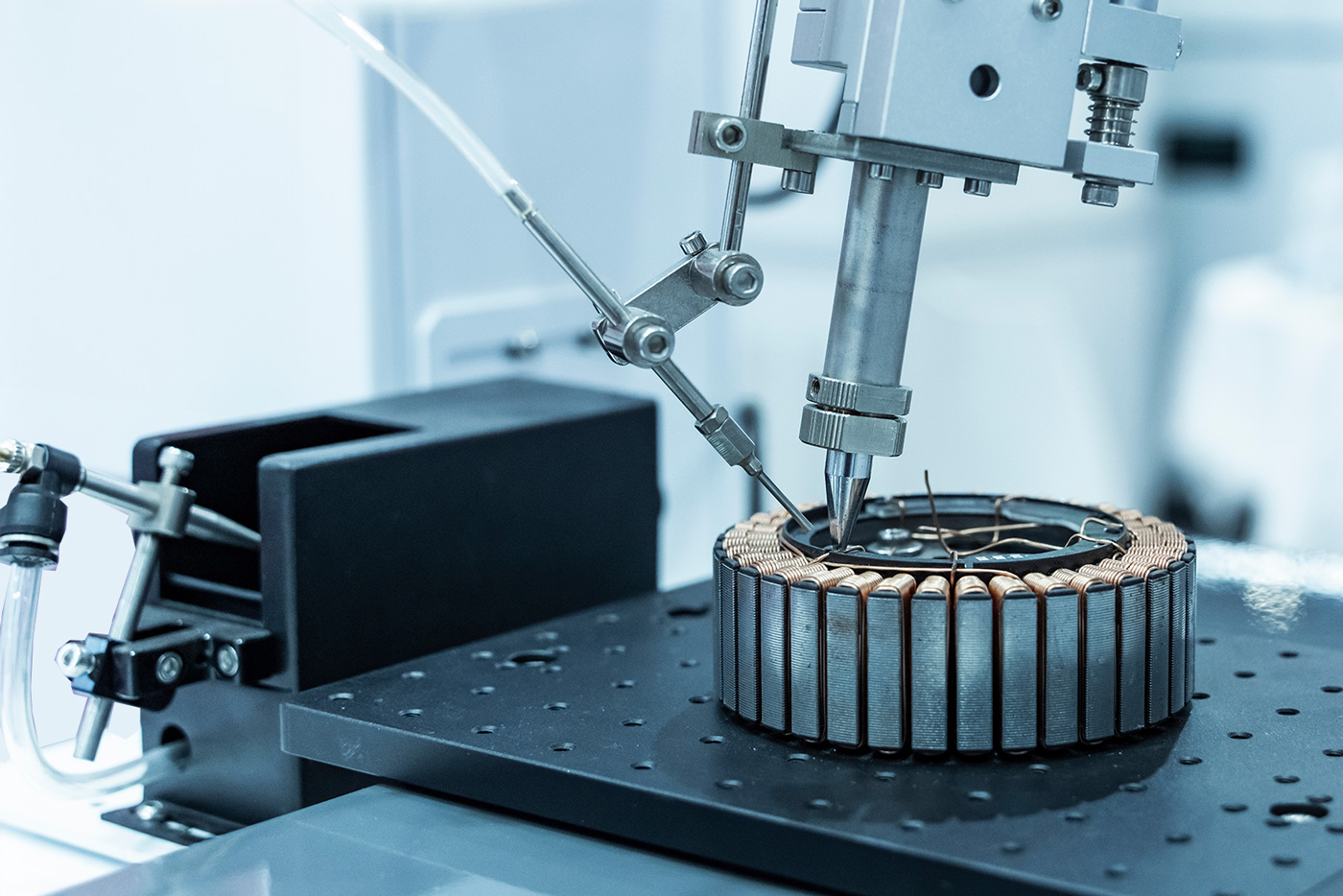

Welding applications - Precise metal powder solutions for reliable welding

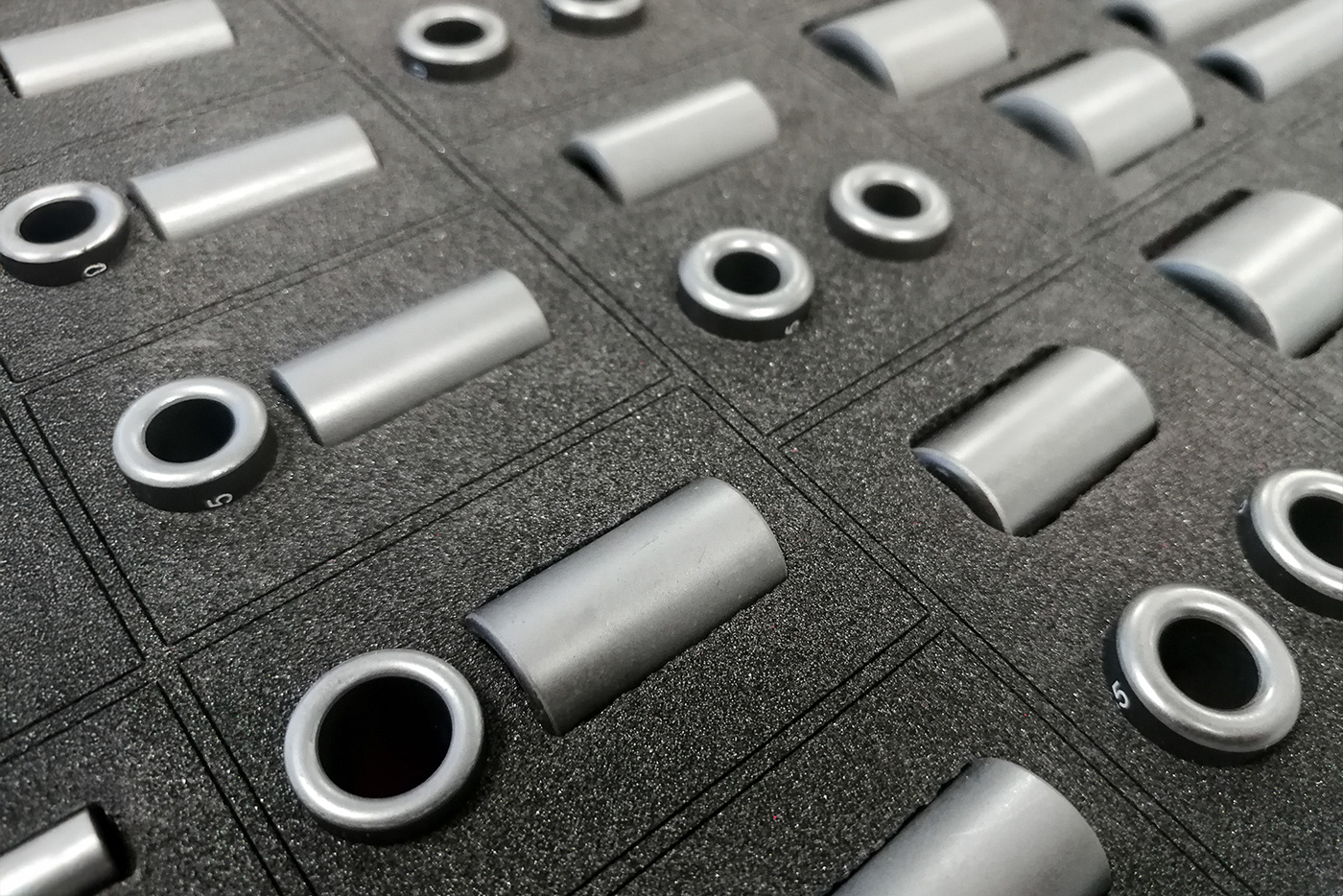

Welding applications are indispensable for joining and manufacturing metal components in numerous industries. Whether in the construction, automotive or aerospace industries, precise and reliable welded joints are crucial for the stability and durability of the end products. Our high-quality metal powders provide the ideal basis for various welding processes by combining outstanding properties such as high melting points, excellent flow properties and optimum particle distribution.

The advantages of our metal powders for welding applications include

- Excellent melting points: Enables the welding of metals with high temperature requirements.

- Optimised flow properties: Ensures even connections and minimises material loss.

- High purity: Reduces contamination and improves the quality of weld seams.

- Precise particle distribution: Ensures consistent results and reliable connections.

- Versatility: Suitable for various welding processes such as MIG, TIG, laser and electric welding.

Our metal powders support a wide range of applications, including the production of robust structures, precise components and durable connections that withstand the highest demands.

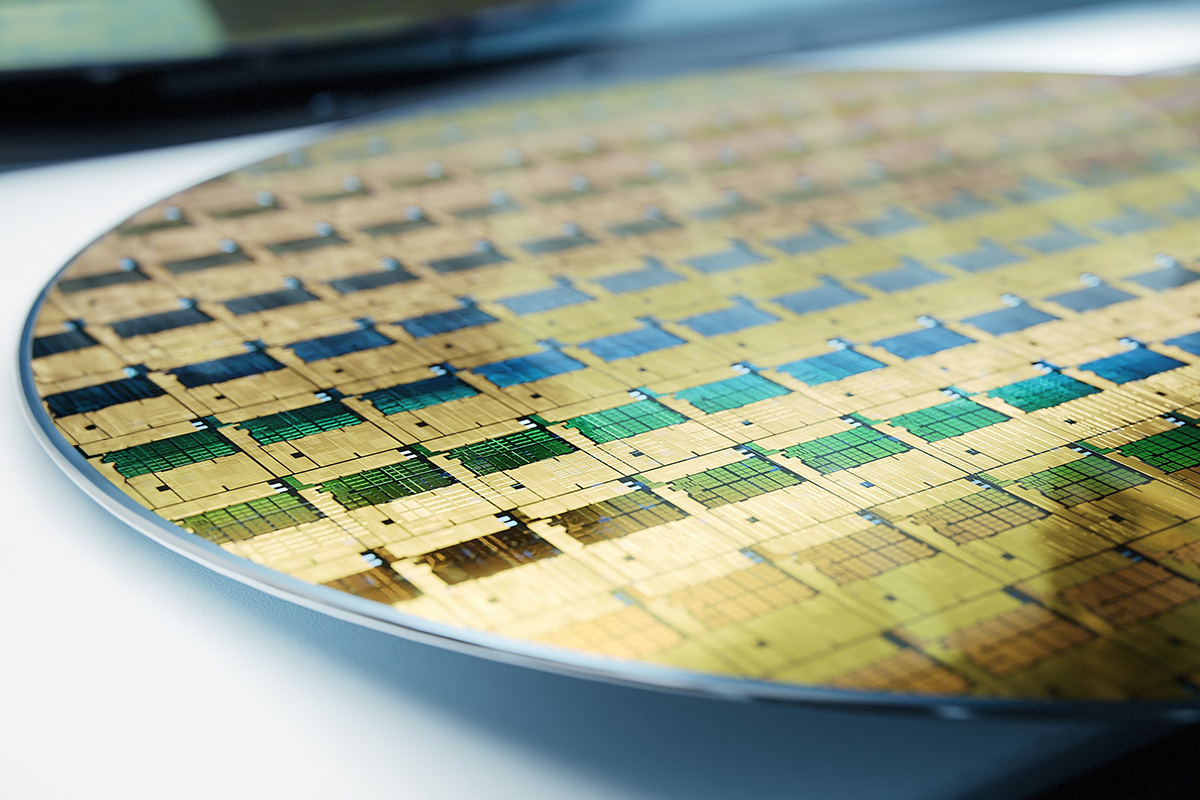

Suitable metal powders for welding applications

We are your reliable source for metal powders such as

- Nickel powder: Ideal for high-strength and corrosion-resistant welded joints.

- Aluminium powder: Perfect for lightweight yet robust welding applications in lightweight construction.

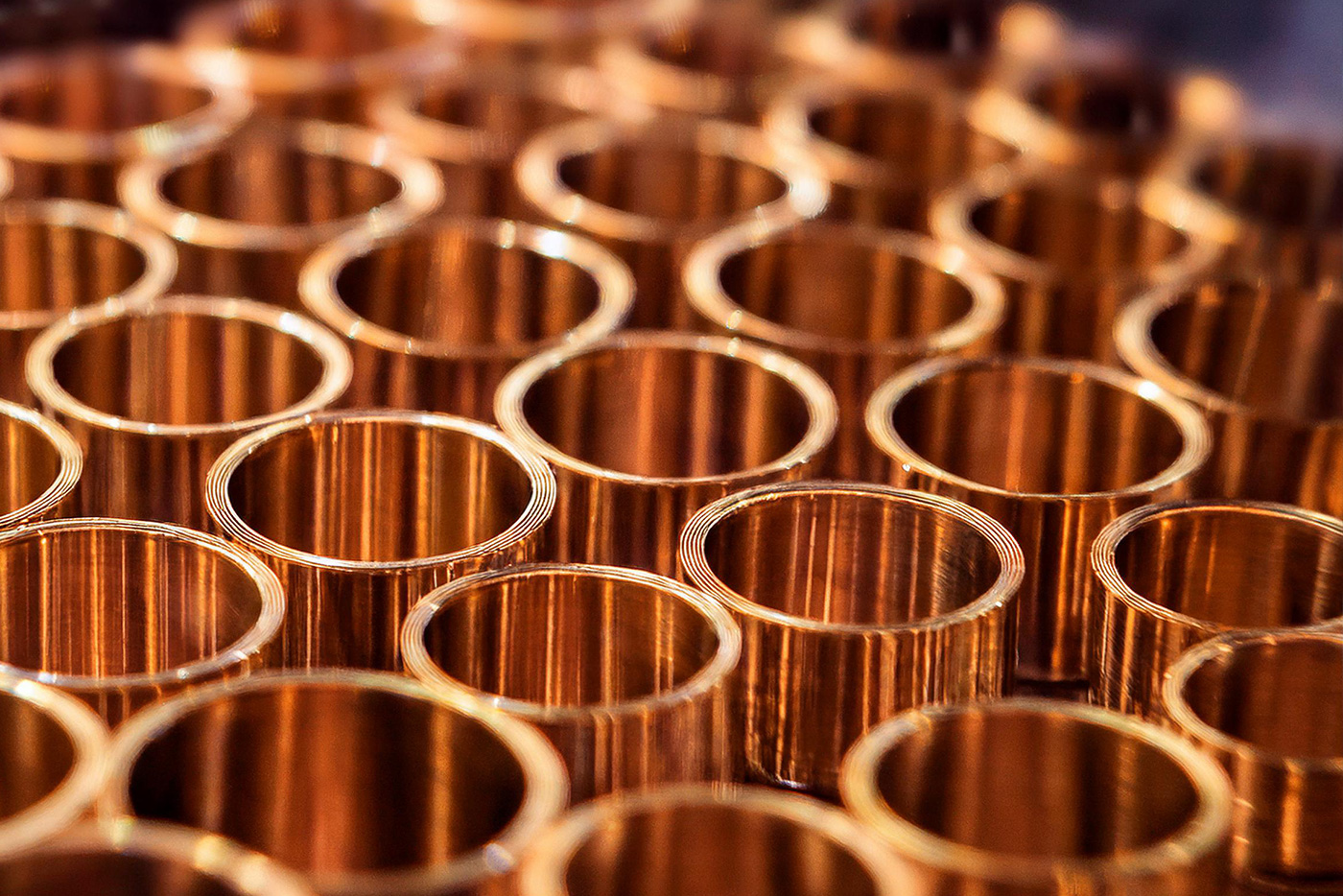

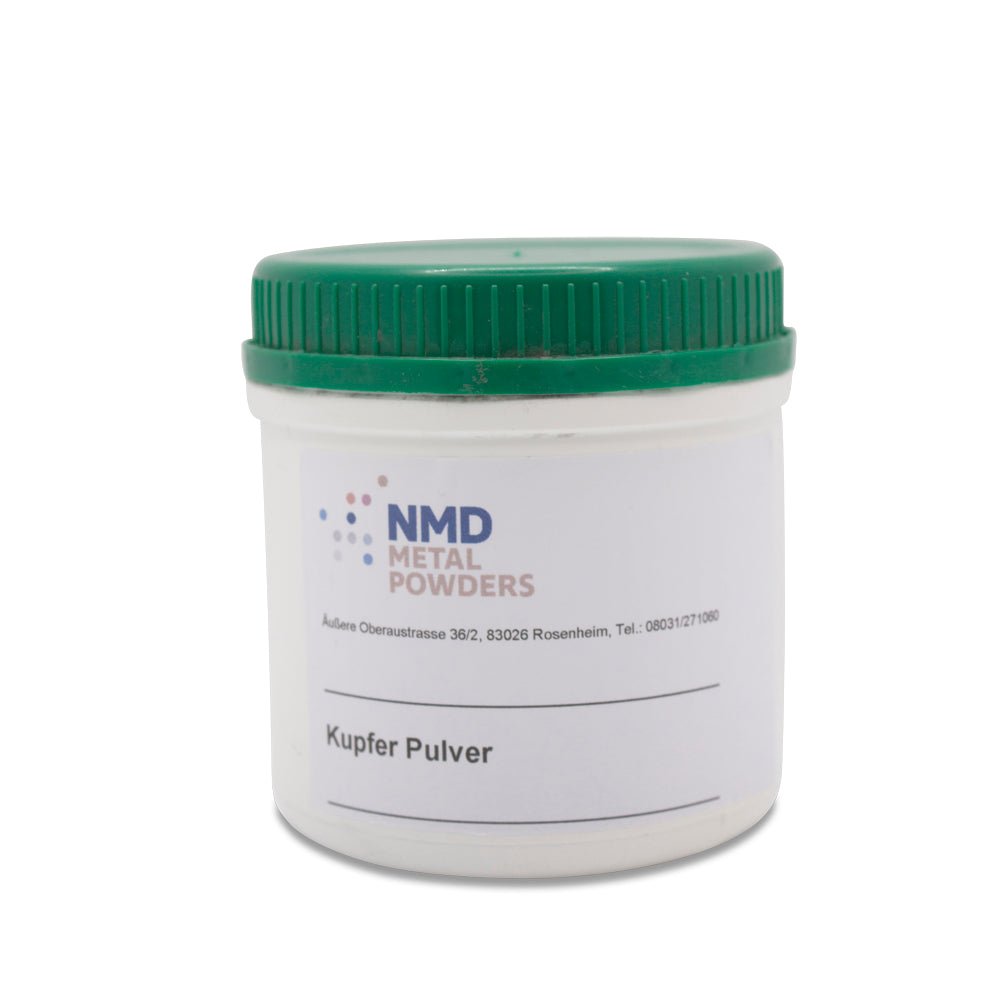

- Copper powder: Ideal for electrical and thermal welding processes.

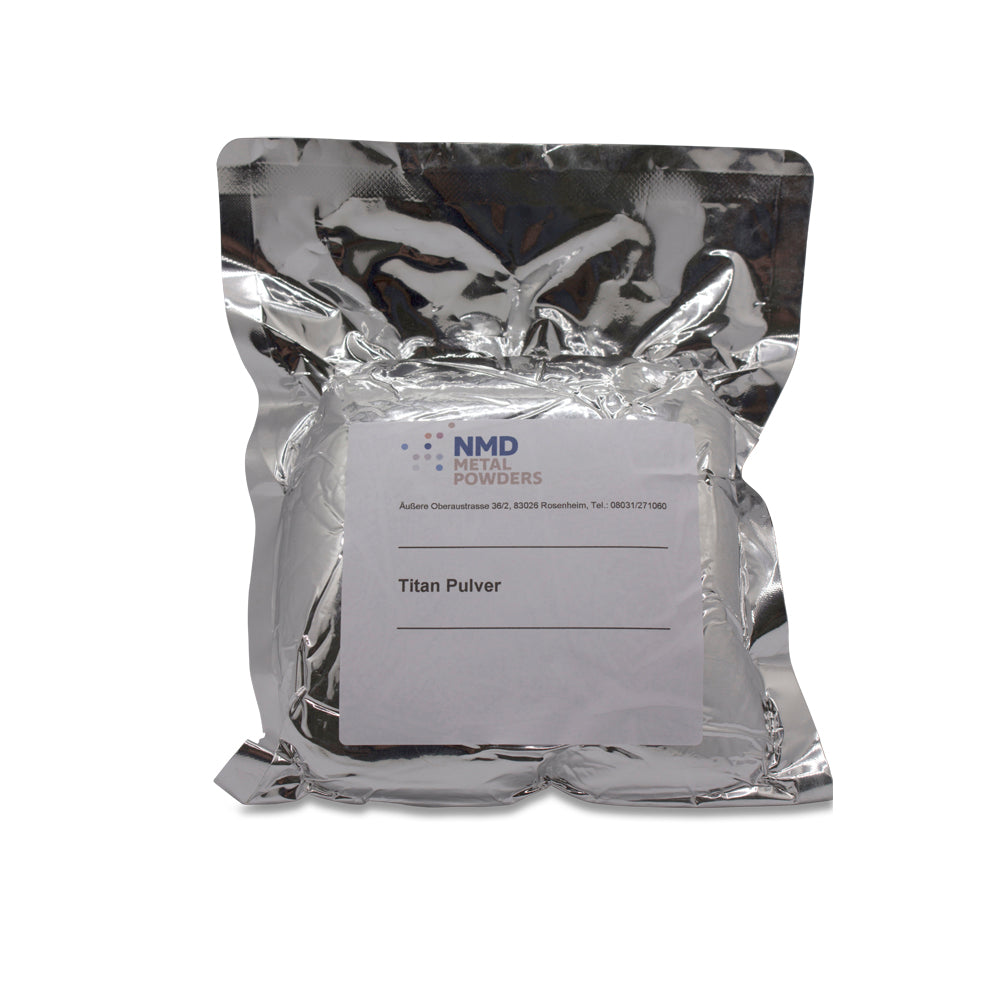

- Titanium powder: Excellent for demanding welded joints in the aerospace industry.

- Steel powder 316 L: For corrosion-resistant and durable weld seams in industry.

- Zirconium powder type 1 CL2: For special welding applications with high reactivity and corrosion resistance.

Customers from these industries benefit from our metal powder solutions for welding applications

Welding applications are used in a wide range of industries, including

- Automotive industry: Manufacture and repair of body and engine components.

- Aerospace: Production of structural components and engines.

- Construction: Construction of buildings, bridges and infrastructure projects.

- Shipbuilding: Construction and maintenance of ships and offshore structures.

- Machine and tool construction: Manufacture of precision tools and machine components.

- Energy generation: Production of turbines, boilers and other power plant components.

- Medical technology: Manufacture of surgical instruments and implantable devices.

Automotive industry

Aerospace

Machine and tool construction

Power generation

Manufacturing industries

Why NMD Metalpowders?

The quality of the metal flux directly influences the efficiency and reliability of your welding applications. Low-quality flux can lead to uneven weld seams, increased wear and shortened service life of your components.

With NMD Metalpowders, you get high-quality metal powders that are specially optimised for welding applications. Our many years of expertise in the development and supply of customised powder solutions ensure consistent and reliable welding results that meet your specific requirements.

Nadine Rajner

Your contact person

The advantages of professional powder coating by NMD:

- Speed: Speed up your production processes with our fast powder procurement.

- Optimisation: Achieve higher quality at lower cost with our customised powder selection.

- Anonymity: Protect your intellectual property and strengthen your market position.

- Savings: Avoid costly bad purchases. Maximise your profits with our expertise.

Machines run smoothly

because you have the right powder.

Consistently high quality

for your products because you can rely on our global supply chains.

Serenity and security

in your work, because you have us at your side as your partner.

Metal powder for welding applications

Not found your metal powder?

No problem! If your specific metal powder for welding applications is not listed here, we are guaranteed to find the right solution for your requirements.

Do you have any questions?

Contact us for individual advice or our customer service on weekdays from 09:00 to 16:00.