Classic galvanising has long been part of the standard repertoire of surface technology. However, the use of ultra-fine zinc dust is also becoming an increasingly common option. Find out here what is behind this and what advantages it has.

Favoured partner in coating technology

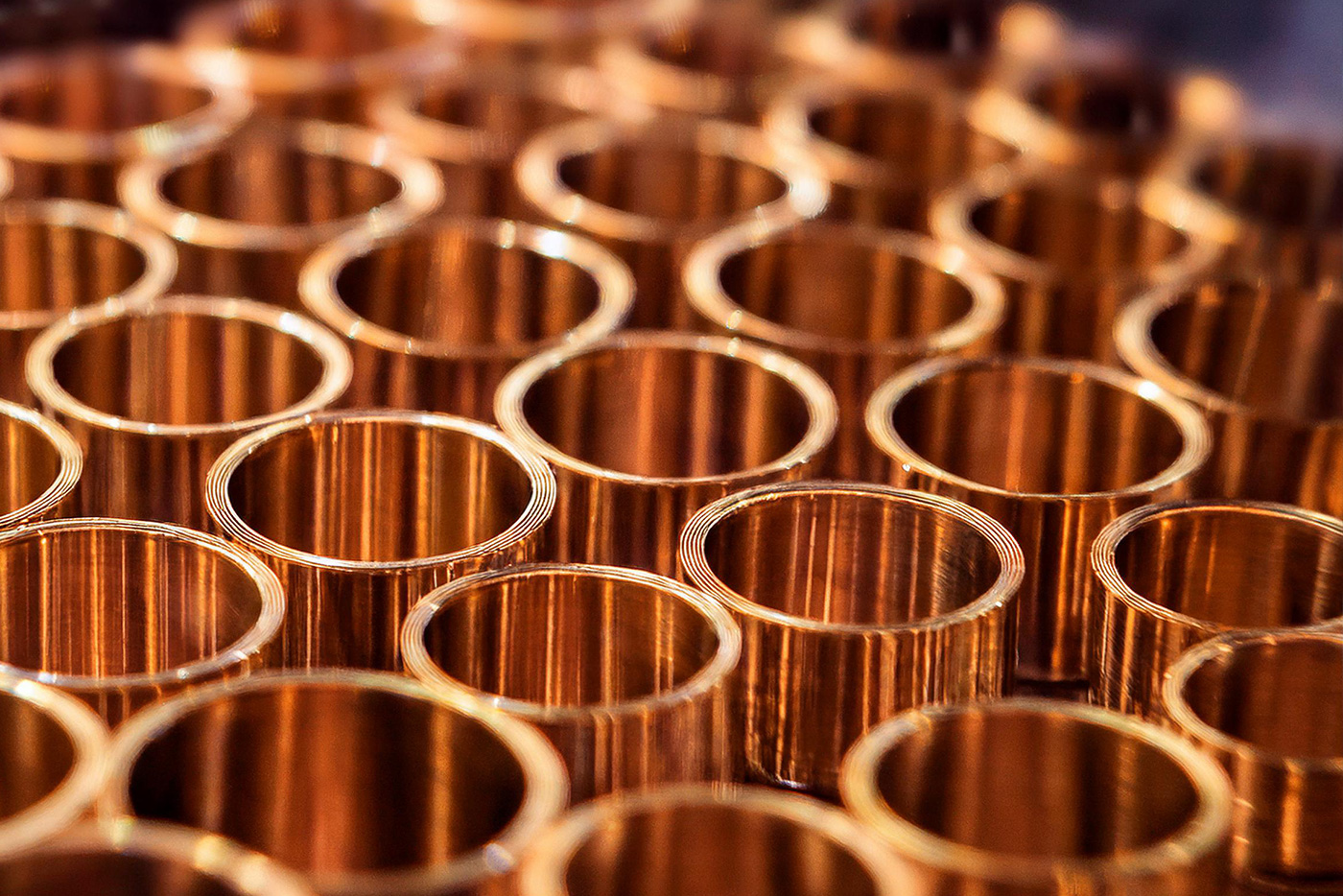

Traditional galvanising is often used to give materials such as steel or iron certain properties. The oldest method is hot-dip galvanising, in which the components are immersed in liquid zinc. However, a modern alternative that has now become established is Use of zinc dust is becoming more and more established. Spherical or platelet-shaped particles are usually used for coating with this dust. The fine metallic pigments are produced by condensation or atomisation.

Both for private use in the form of easy-to-use sprays and for industrial use, zinc dust can offer many advantages in the field of surface technology and coatings.

Reason 1: Zinc dust offers the best corrosion protection

Users rely on galvanising or a coating based on zinc dust primarily because of the reliable corrosion protection. Moisture and humidity cannot attack the material as easily and are better protected against rust and other damage.

Zinc dust can be used for a wide range of surface treatments. The coating can be used wherever metals are exposed to weathering and moisture - for example:

- Mechanical engineering

- Fences and fittings

- Exhaust systems

- Car bodies

- Tubes

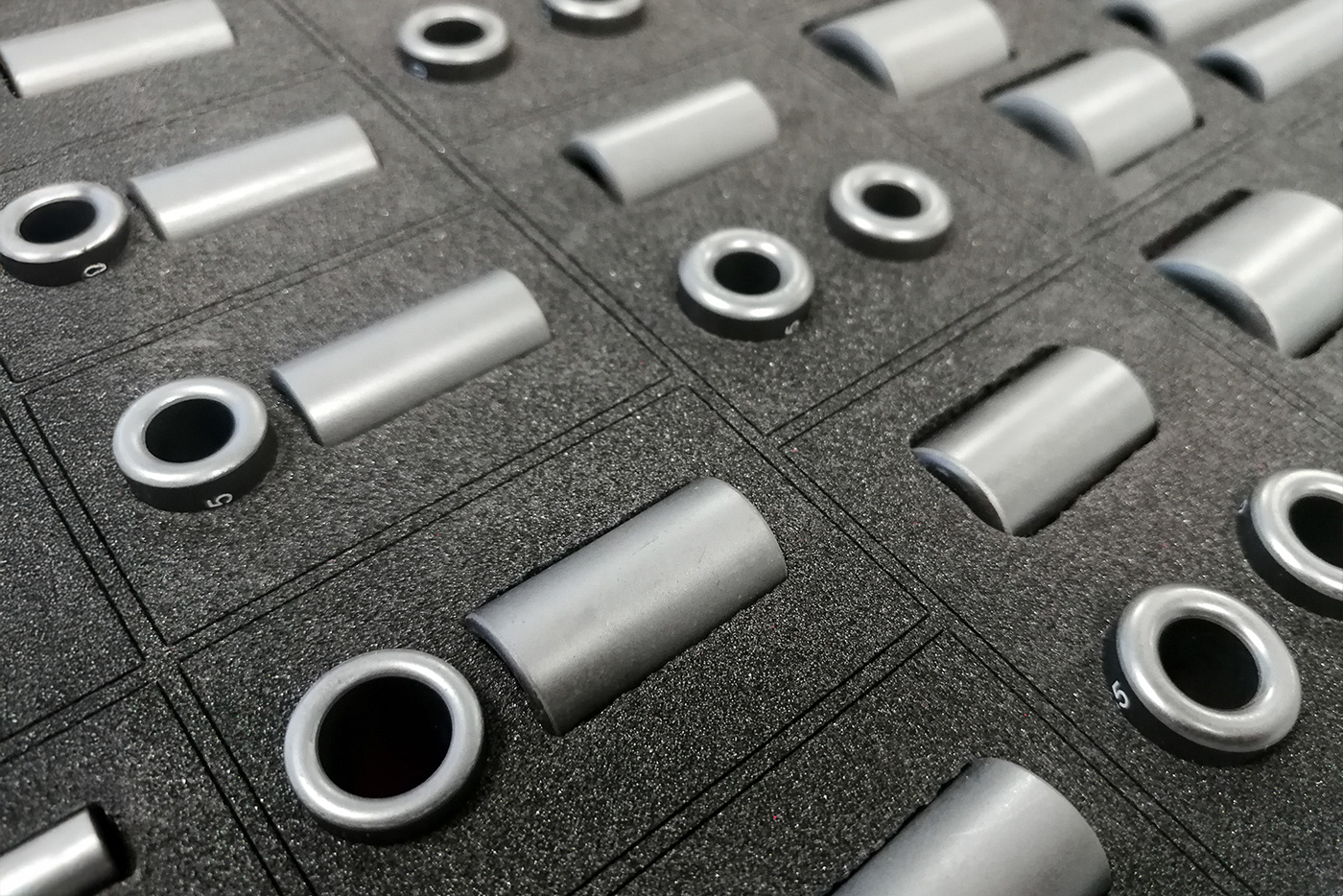

- Special protection for weld seams, drill holes, threads, screws or nuts

- As a primer

- As an intermediate layer for spot welding

- In sectors such as the automotive industry, shipping, bridge construction and offshore technology

Reason 2: The metal dust is easy to use

Coating with zinc dust is relatively easy to carry out and is suitable for many substrate materials. Unlike hot-dip galvanising, for example, the workpiece does not have to withstand high thermal stress. Instead, other processes are conceivable when using zinc dust:

- The zinc dust is used, among other things, as Spray. The basis here is often Synthetic resinswhich ensure even distribution and adhesion to the substrate.

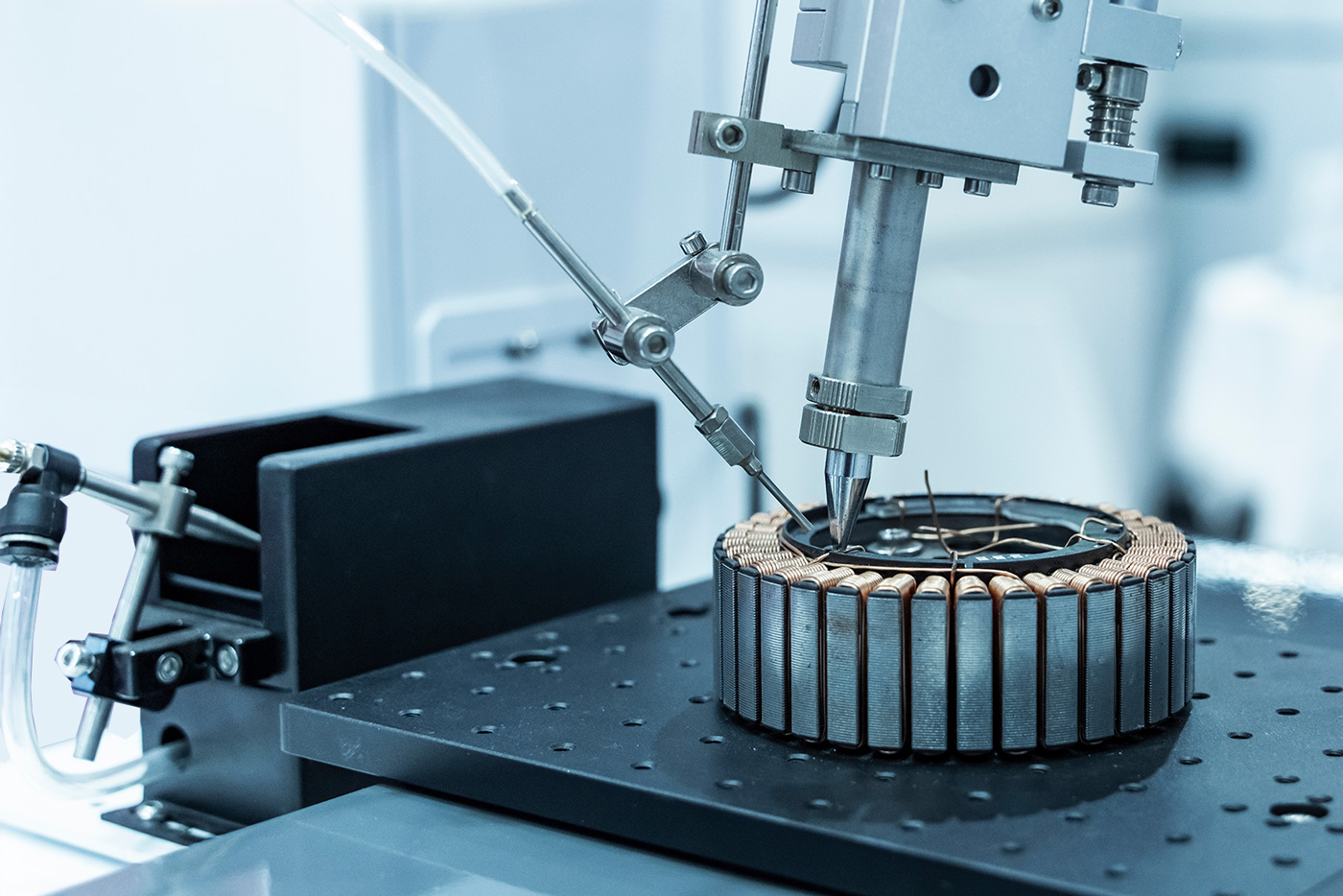

- Alternatively, the procedure of the Spray galvanising a variation of flame spraying. This involves melting the zinc powder, atomising it with compressed air and applying it to the workpiece. However, the substrate material should have a certain structure on the surface - zinc dust tends to adhere poorly to surfaces that are too smooth.

- Even with the so-called Diffusion galvanising zinc powder forms the basis. The fine dust is vaporised at high temperatures of several hundred degrees Celsius and combines with the material to be processed as part of the diffusion process. This process is particularly practical for complex components with hard-to-reach areas.

Reason 3: The look is also right

Zinc dust is often also called Additive in varnishes or paints used. A coating therefore has a 2-in-1 effect here: on the one hand, the positive properties of zinc - such as corrosion protection - can be utilised. On the other hand, the desired appearance is achieved in the same step. With conventional hot-dip galvanising, painting or coating must be carried out in an additional production step, such as powder coating. The use of zinc dust therefore saves valuable resources. It also avoids the problem of blistering that can often occur when powder coating galvanised steel.

Zinc dust is always a good choice

Whether as pure rust protection, as a primer for further processing or in combination with paints and varnishes: Zinc dust has become indispensable when it comes to the surface treatment of materials such as steel or iron. The wide range of possible uses and variations in application make the fine metal powder interesting for a large number of target groups and areas of application. Perhaps for you too?