Powder metallurgy describes a Innovative manufacturing processwhere Metal powder is transformed into solid and extremely robust components by pressing and subsequent sintering. This technology opens up new possibilities for the industry, as it allows, Components with complex geometries and exact specifications that are difficult or impossible to realise using conventional methods.

The use of metals in powder form is by no means coincidental, but has clear advantages:

- Significant cost savings compared to alternative manufacturing processes, for example through reduced material loss and simplified process steps.

- Specific material propertiesthat cannot be achieved with conventional manufacturing processes. These special properties include controlled porosity, optimised mechanical properties, precise magnetic and electrical properties and special high-temperature resistance.

Metal powders are produced using various processes, including Mechanical shredding, Electrolytic deposition, chemical reduction or Atomisation of liquid metal.

The properties of the powders, in particular Grain size, Grain size distribution, Shape, Surface finish and inner structurehave a significant influence on further processing and the quality of the final components.

Powder metallurgy has become an indispensable technology in numerous industries. Its strength lies in particular in the Efficiency, Precision and Sustainabilityas there is virtually no material waste and resources can be optimally utilised.

Industrial applications of powder metallurgy

Powder metallurgy is used in a wide range of industries and enables high-quality solutions for demanding production requirements.

Automotive industry

The Automotive industry benefits particularly strongly from powder metallurgy processes. Through Sintering process The result is components that impress with their low weight and high strength - such as gear wheels, control elements or complex engine parts.

Metal powder from Magnesium alloys or aluminium alloys enable the production of lightweight, resilient components that contribute significantly to fuel savings and increased efficiency.

Aerospace

In the aerospace industry, high demands are placed on Material strength, reliability and Low weight decisive. Powder metallurgy enables the production of high-precision components such as turbine blades or parts made from Titanium alloyswhich can withstand extreme loads and reduce weight at the same time.

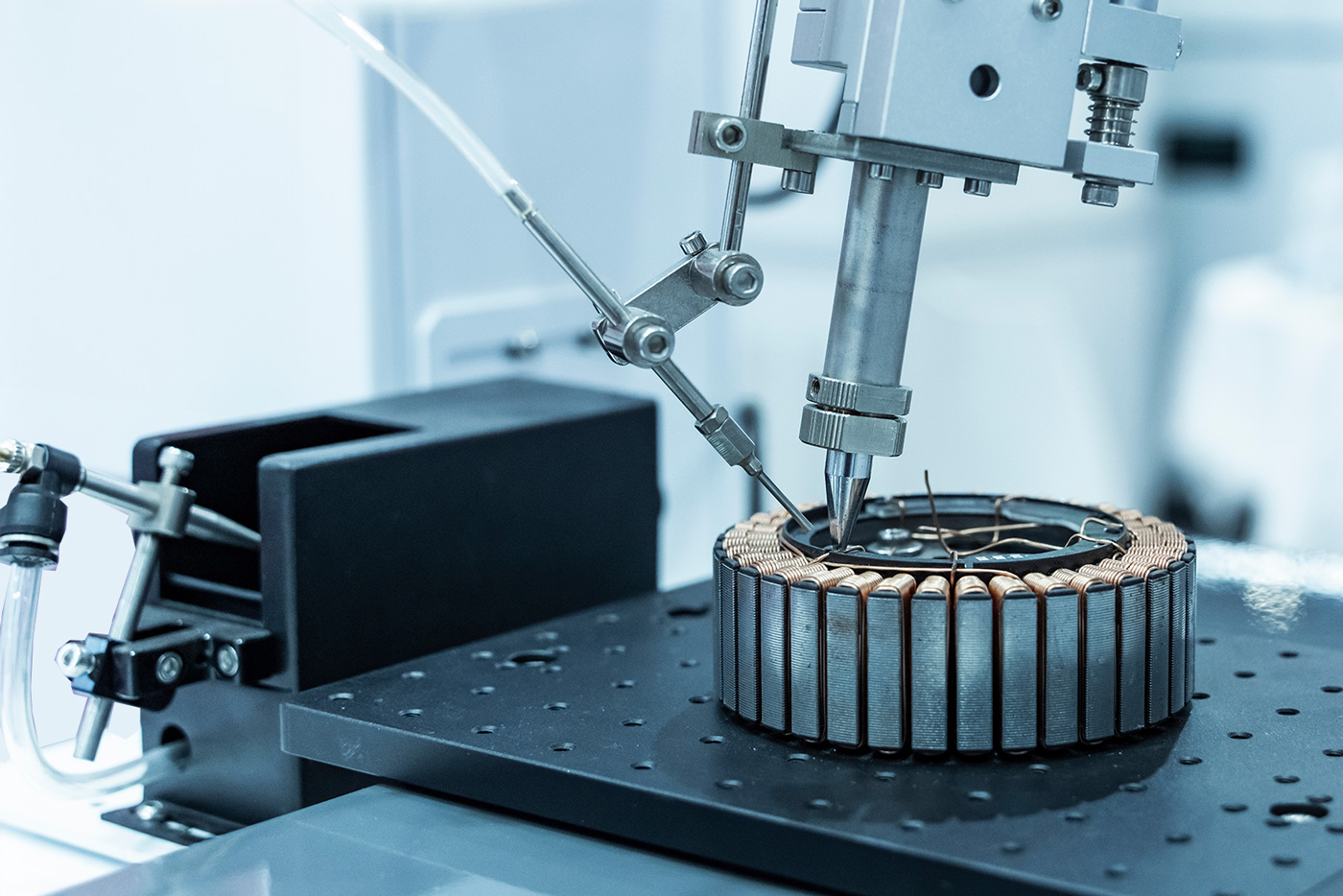

Machine and tool construction

Powder metallurgical processes are used here primarily for the production of complex Sintered moulded parts used. High-precision and wear-resistant components such as Gear wheels or Guide elements benefit from the precise shaping and mechanical properties of powder metallurgy.

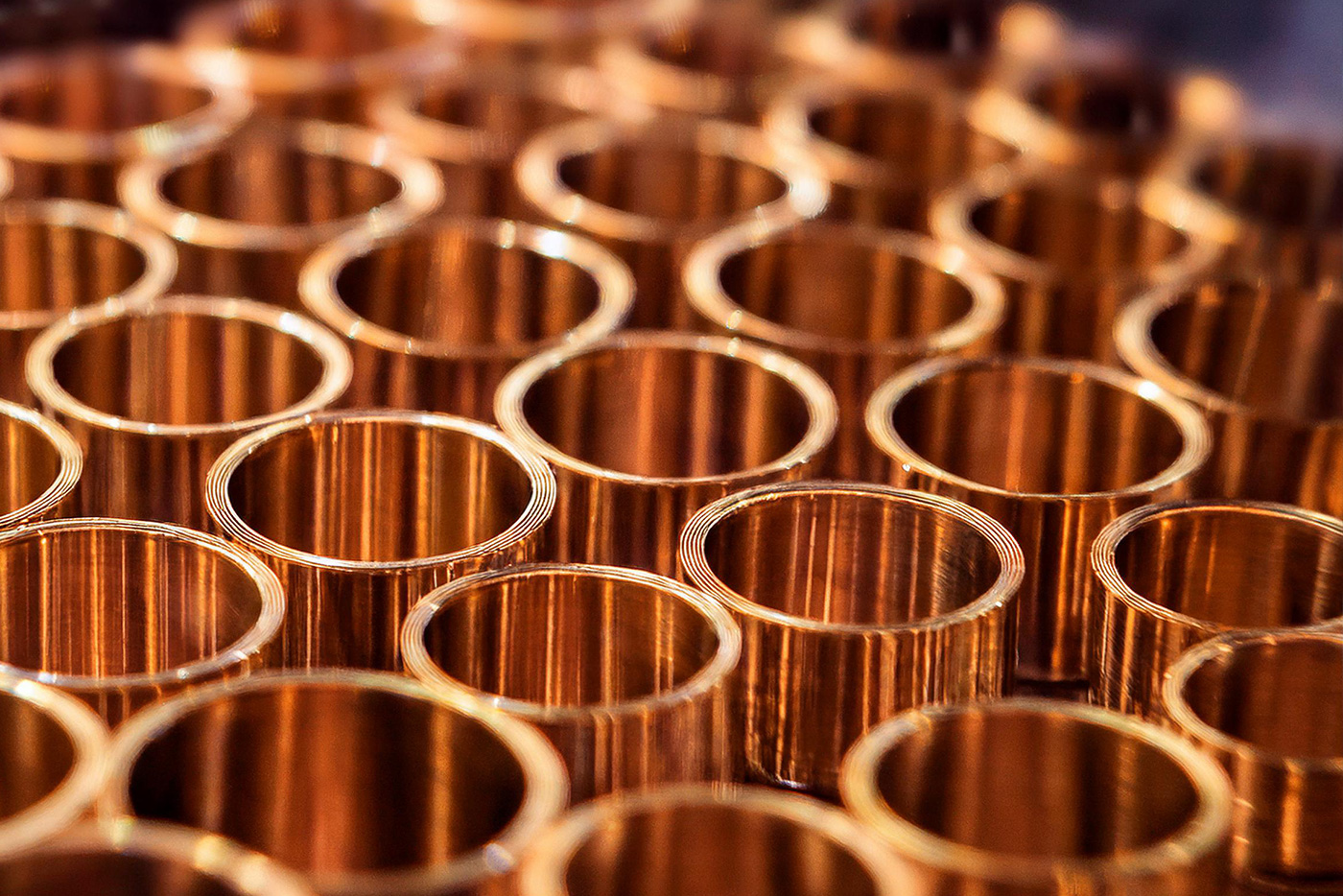

Electrical engineering

In electrical engineering, metal powders, especially ultra-fine copper powderare of central importance. They enable Excellent electrical conductivity and are used in printed circuit boards, switches and electrotechnical contact components.

Power generation

Powder metallurgy is also essential in energy generation. Specialised powder solutions enable Durable and reliable components in wind turbines, gas turbines or solar technology. Nickel and aluminium powder play a central role here, especially in energy storage systems.

Manufacturing industries

The manufacturing industries benefit from the Flexibility powder metallurgical processes. Whether in the field of metal processing, the plastics industry or chemical process engineering - customised metal powders such as Ferrites or Nano metal powder specific production requirements can be optimally fulfilled.

Diverse areas of application for powder metallurgy

Powder metallurgy opens up a multitude of specific fields of application:

Additive manufacturing

In the additive manufacturing (3D printing) complex metal components can be manufactured quickly and precisely. Titanium Grade 5 powder, ultra-fine copper powder UF2 or Aluminium silicon powder are ideally suited for this purpose.

Hard and soft soldering

Soldering powder such as SAC 305 or Sn63Pb37 guarantee high-quality soldered connections. They offer excellent mechanical properties and are used for demanding connections in electronics and industrial applications.

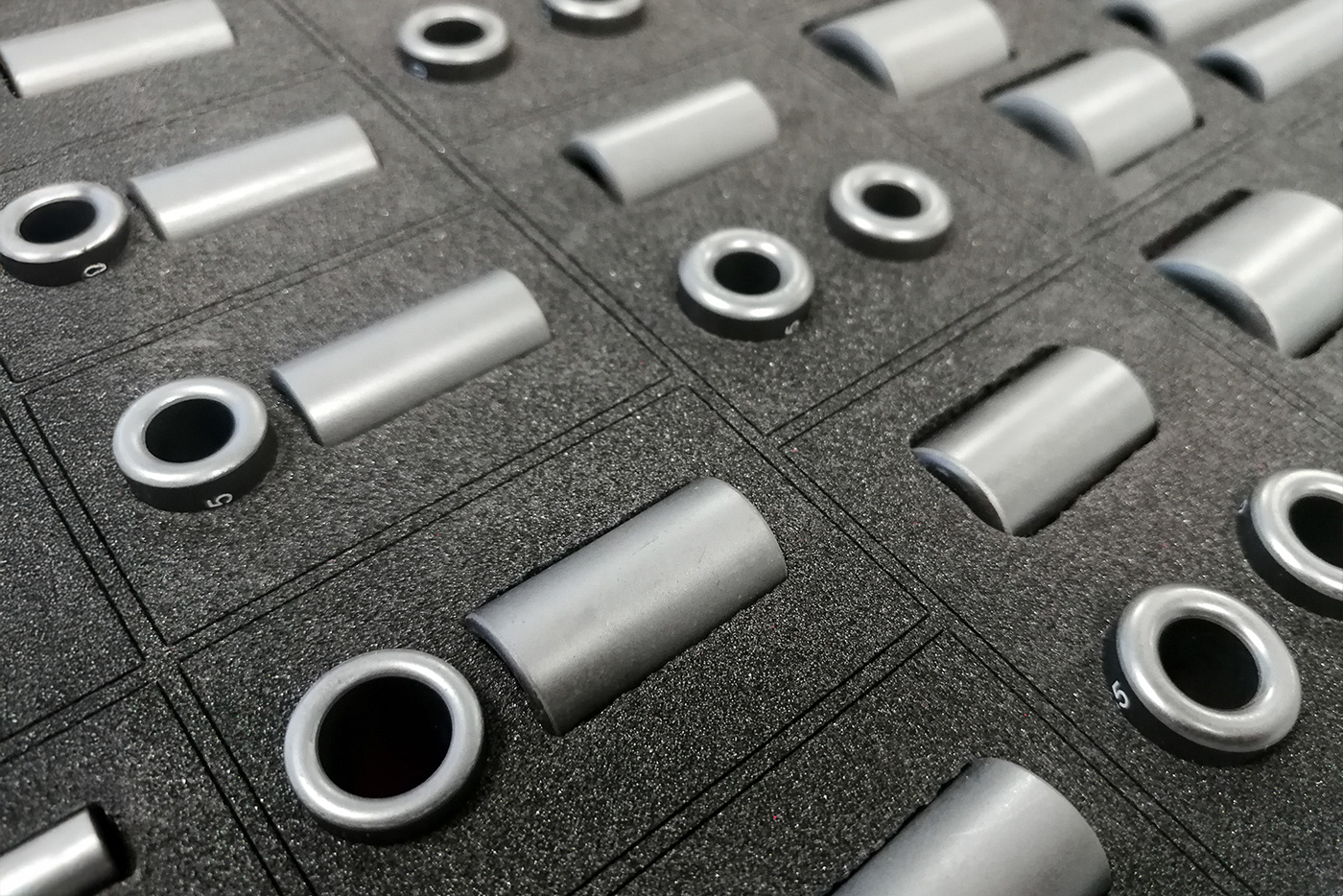

Sintered moulded parts

Precise and robust sintered moulded parts are produced by pressing and sintering metal powders such as Stainless steel 316L. This technology delivers components with excellent dimensional accuracy and high mechanical strength.

Metal injection moulding

Metal injection moulding combines powder metallurgy with injection moulding technology and enables the cost-efficient production of complex components in large series - ideal for the automotive and electronics sectors.

Solid lubricants

Metal sulphides such as Tungsten and Molybdenum disulphide significantly improve the friction conditions of moving parts and extend their service life in machines and vehicles.

Surface coating

The use platelet-shaped or ultra-fine powder enables high-quality surface coatings that significantly improve the wear and corrosion resistance of components.

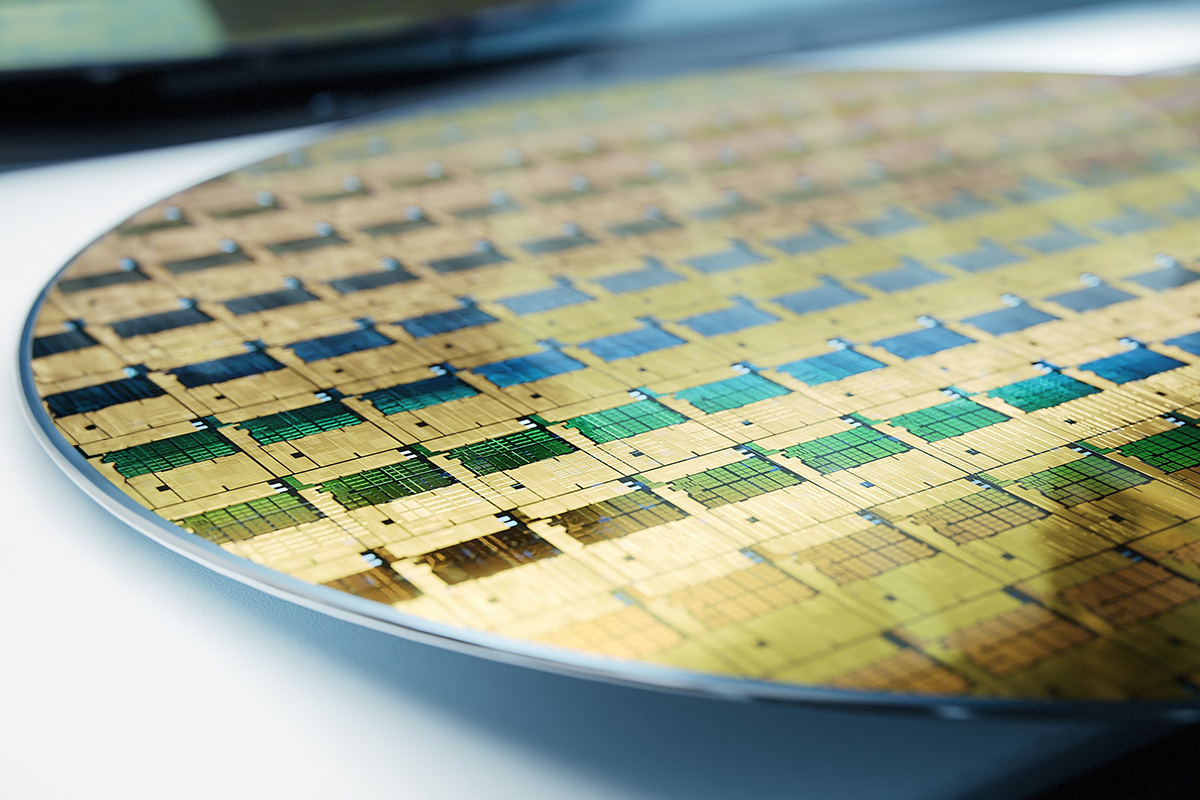

Semiconductor Technology & Electronics

High-purity metal powders are indispensable for electronics production. They ensure Excellent electrical conductivity and enable dense circuit designs, especially in semiconductors and electronic components.

Magnetic applications

Ferrite powder, in particular NiZn and MnZn Ferritesare essential for electromagnetic applications. They are used in electric motors, transformers and various sensors.

Potentials & solutions through powder metallurgy

The continuous development of powder metallurgy opens up great potential for optimising industrial production processes. In times of increasing globalisation, disrupted supply chains and rising quality requirements for industrial components, powder metallurgy is gaining in importance. Quality and reliability of metal powders increasingly important.

Through the targeted use of high-quality metal powders, companies can make their production processes significantly more efficient while at the same time minimising costs. Increase the quality of your components and decisive Competitive advantages achieve.

High-quality powder solutions make it possible to achieve exactly the material properties that are required for specific applications and at the same time reduce Production risks and downtimes.

Particularly in this day and age, when companies with unforeseeable supply bottlenecks and growing customer requirements When faced with a wide range of challenges, high-quality and reliably available metal powders offer decisive advantages. Nevertheless, quality problems with metal powders are a serious challenge that needs to be overcome.

Avoid quality problems with metal powders

The use of inferior metal powders can have serious consequences: Low purity, Poor flowability and Uneven particle size distribution lead to quality losses, production downtime and increased costs.

NMD offers high-quality, customised metal powder solutions and individual advice to meet these challenges. Customers benefit from over 25 years of experience, reliable supply chains and a collaborative partnership.